An inverter heat dissipation system based on semiconductor refrigeration

A heat dissipation system and semiconductor technology, applied in refrigerators, refrigeration and liquefaction, machines using electromagnetic/magnetic effects, etc., can solve problems such as increased machine weight, evaporator volume limitation, and overall machine volume increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

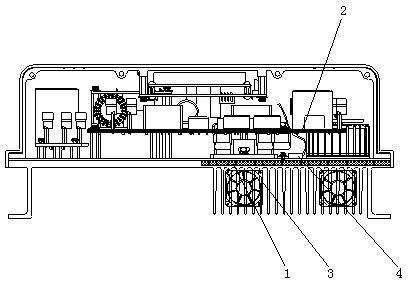

[0016] Such as figure 1 As shown, the present invention provides an inverter heat dissipation system based on semiconductor refrigeration, including a semiconductor refrigerator 1, an intelligent controller 2, and a fan 3, wherein the heat-absorbing surface of the cold end of the semiconductor refrigerator 1 is closely connected to a high-power heating device. contact, and the heat dissipation surface of the hot end is provided with a fan 3, and the fan 3 is started under the control of the intelligent controller 2, thereby forcibly dissipating heat from the hot end of the semiconductor refrigerator 1.

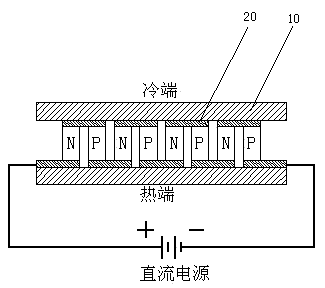

[0017] Cooperate figure 2 As shown, it is a schematic diagram of the principle that semiconductors can realize cooling at one end and heating at the other end. N and P type semiconductors are arranged in pairs, and one end of each pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com