Inductance coupling apparatus and plasma processing equipment applying same

A technology of inductive coupling and plasma, applied in the field of microelectronics, can solve problems such as chip pollution and consumption of built-in inductive coupling coils, and achieve the effect of avoiding consumption and chip pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

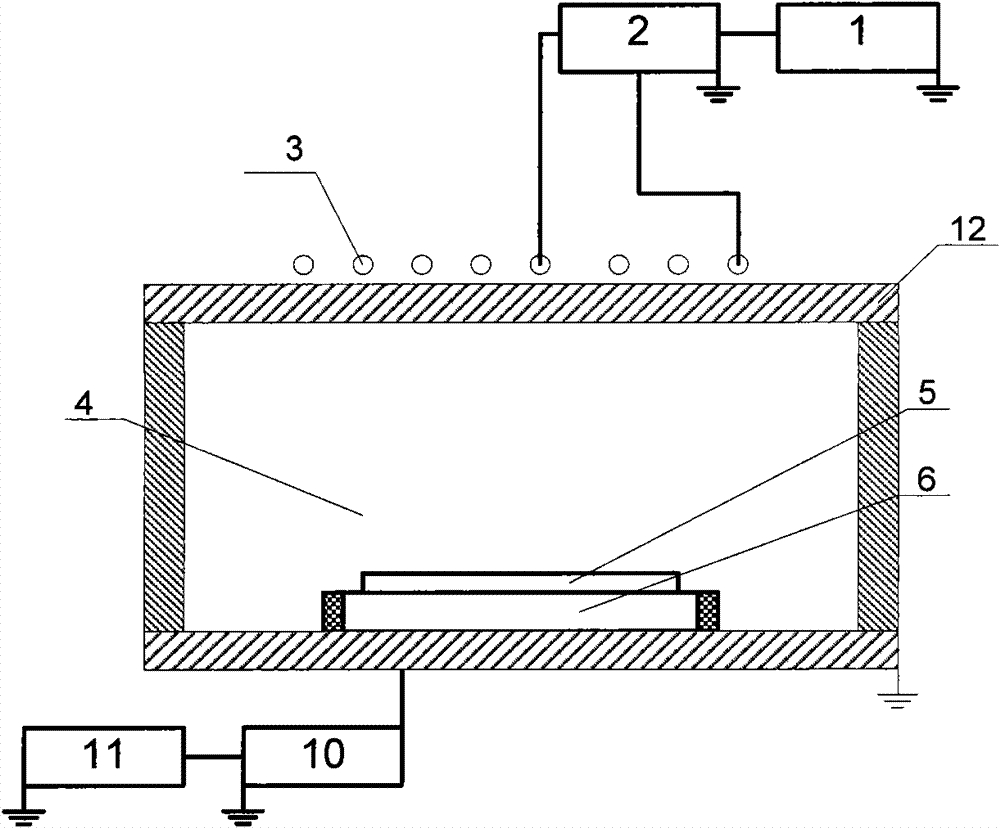

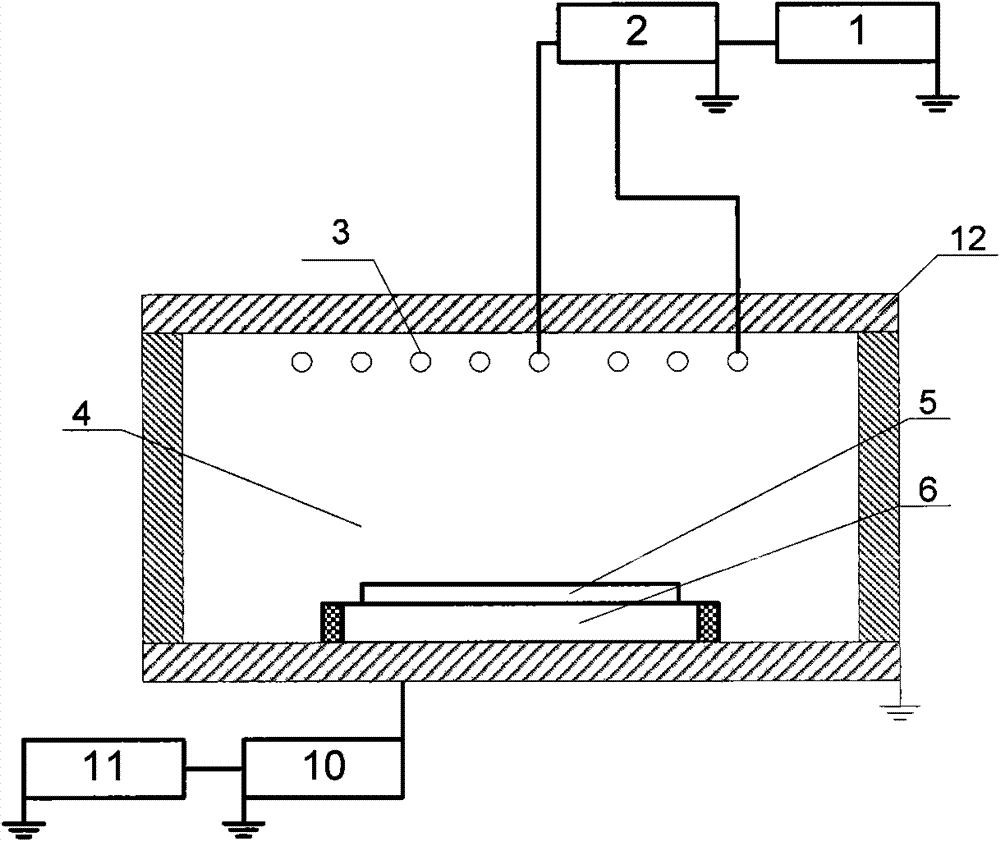

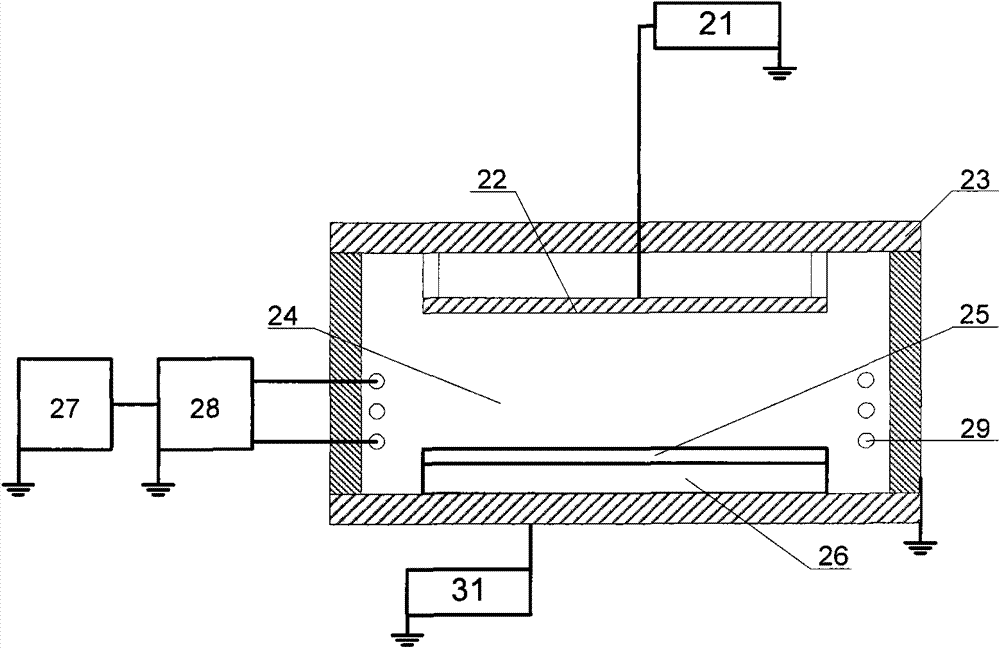

[0029] The inductive coupling device provided by the present invention is mainly used for releasing radio frequency power in the process chamber of plasma processing equipment, so as to excite and maintain plasma. The inductive coupling device includes an inductive coupling coil arranged inside the process chamber, and a radio frequency power supply and a voltage regulation power supply connected to the inductive coupling coil. Wherein, the output end of the radio frequency power supply is connected to a matching device, and then connected to the two ends of the inductively coupled coil via the two output ends of the matching device. The output end of the voltage-regulating power supply can be connected to any end of the inductive coupling coil, which is used to load a positive bias voltage to the inductive coupling coil, thereby suppressing the negative self-bias of the inductive coupling coil. The voltage-regulating power supply can use a DC power supply or a DC pulse power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com