Corn threshing method and corn threshing machine

A corn threshing and thresher technology, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low threshing class, interrupted or crushed, and large broken rate, etc., and achieves long service life and simple structure. , good threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

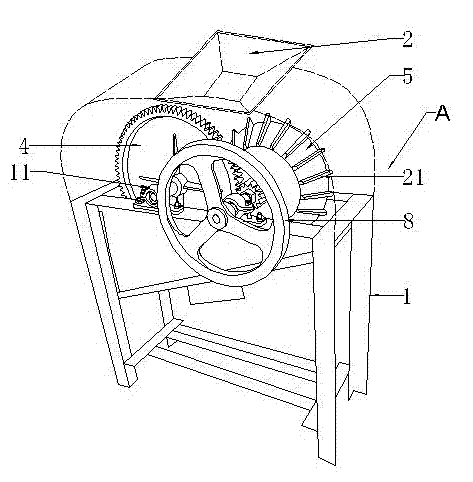

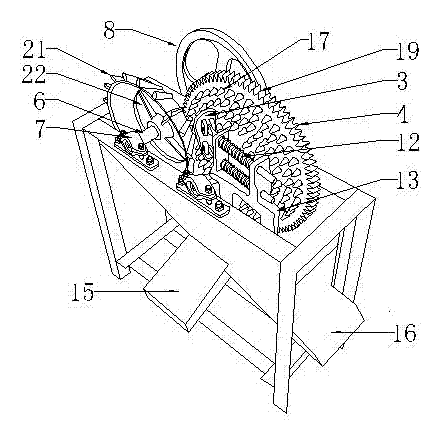

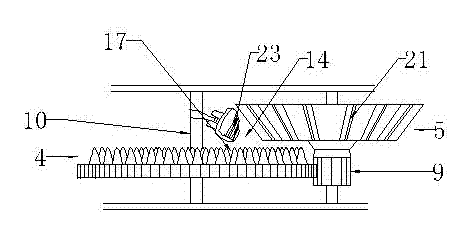

[0023] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , the corn threshing method described in the present embodiment, at first, manually shake or adopt the electric motor to drive the threshing machine to run; put corn cobs in the hopper, and when the corn cobs fall into the machine cavity along the hopper, the corn cobs are guided by the guide plate to make the corn The cobs fall into the threshing chamber, and the corn cobs are threshed by the threshing teeth on the threshing disc and the threshing strips on the guide disc. After threshing, the corn and corn cobs fall onto the corn mesh sieve and are screened out through the corn mesh sieve. , the corn and the corncob flow out from the corn outlet and the corncob outlet respectively to complete corn threshing. The invention has the advantages of good threshing effect, long ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com