Method for separating loin from backbone meat of crisp grass carp

A spine meat and fish back technology, applied in fish processing, slaughtering, food science, etc., can solve the problems of unfavorable added value of grass carp, impact on demand and value, inconvenient eating, etc., so as to improve utilization rate and added value, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

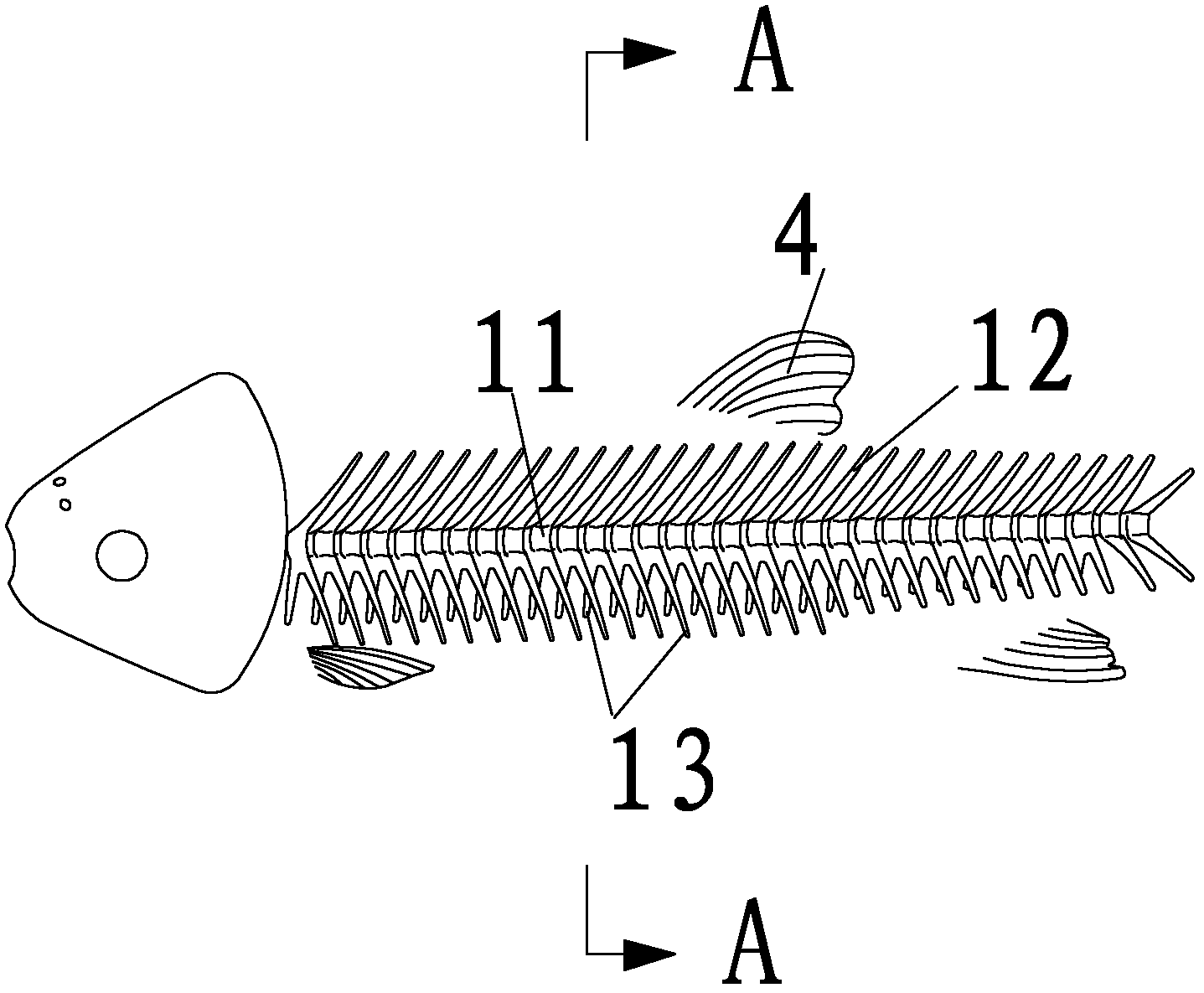

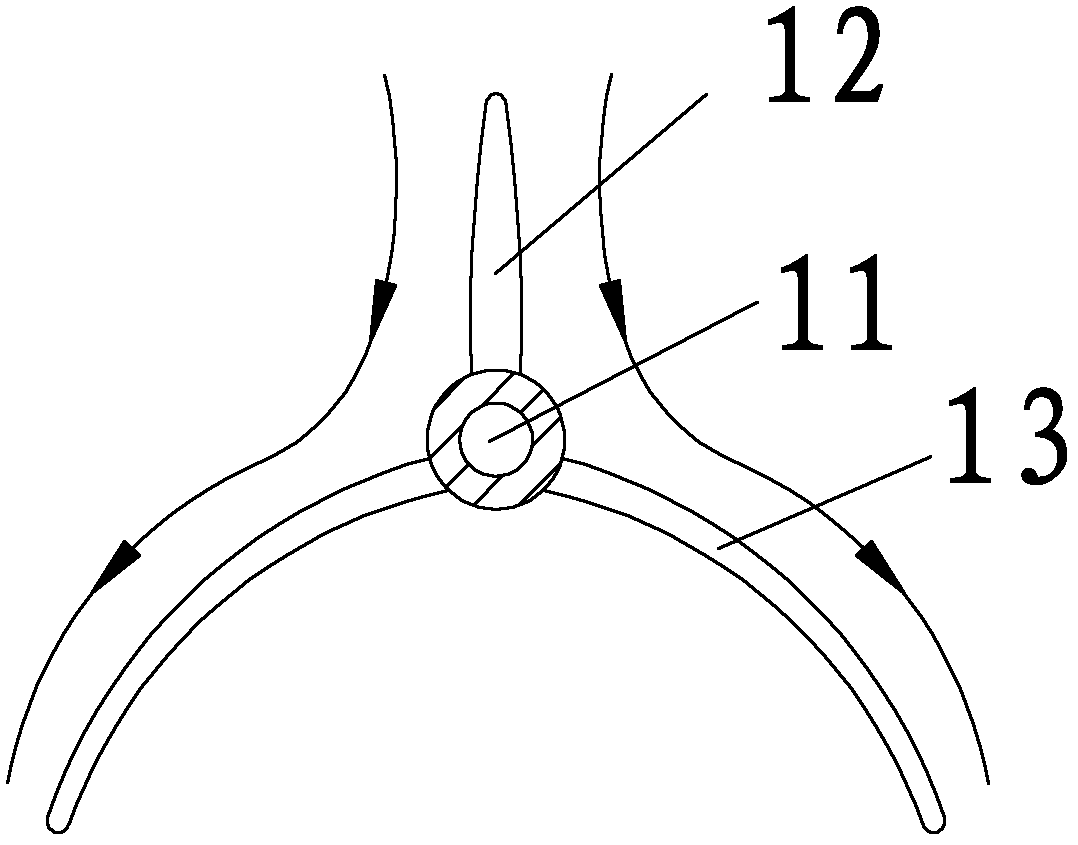

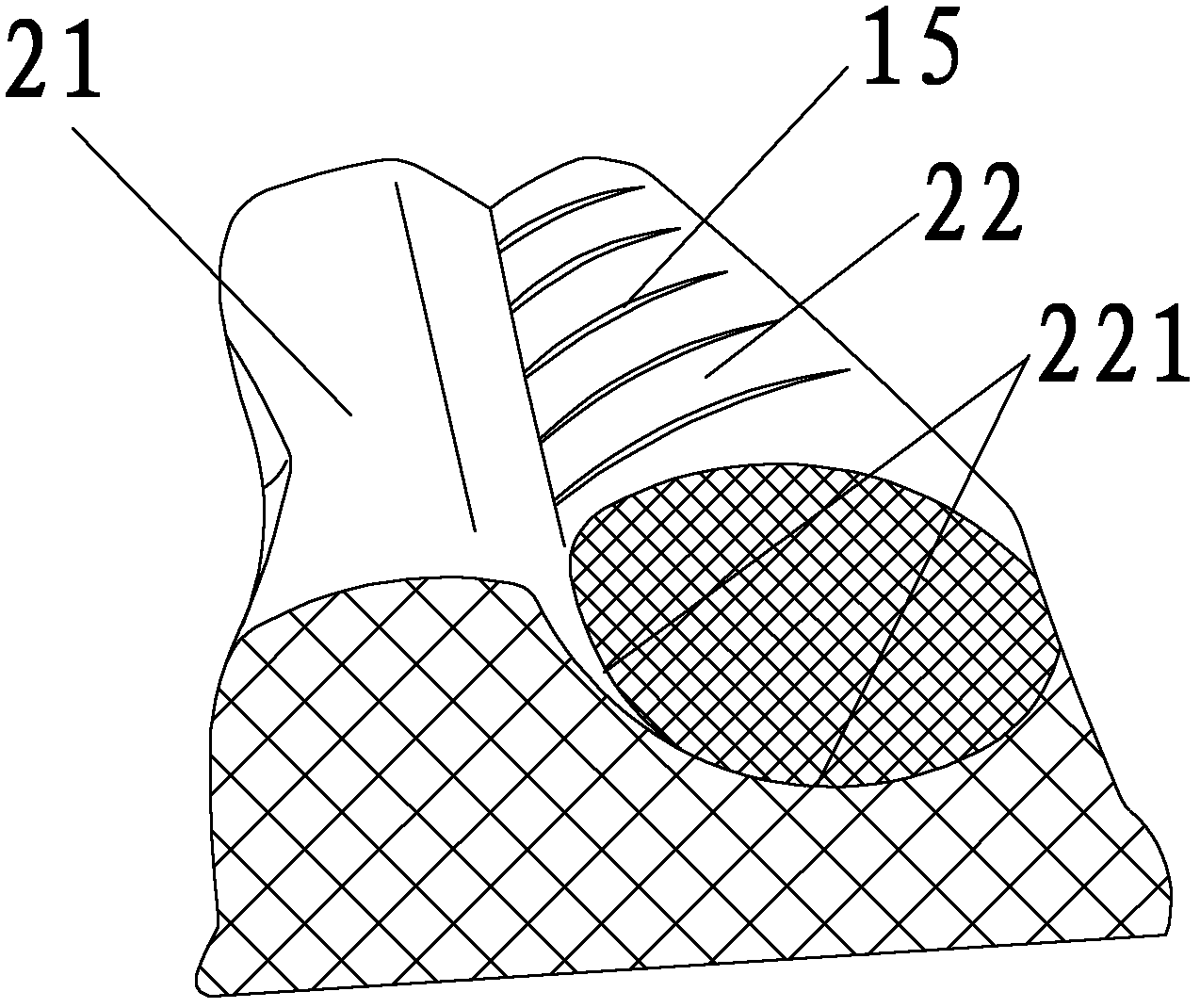

[0014] like figure 1 As shown, the main bones of the grass carp body include fish vertebrae 11 , upper vertebrae 12 , and ribs 13 . like image 3 As shown, there is a strip of fish spine meat 22 surrounded by intermuscular spines 15 near the fish back meat 21.

[0015] like Figure 1 to Figure 4 As shown, follow the steps below to separate the back meat and spine meat of grass carp with crispy meat:

[0016] 1) Cut the knife along the two sides of the dorsal fin 4 of the fish first, and the edge of the knife is close to the upper edge bone 12 of the spine to cut to the spine bone 11, and the fish back meat 21 and the strip fish spine meat 22 surrounded by the intermuscular spines 15 are together with the upper edge bone of the spine. 12 is separated, and then the edge of the knife is cut close to the rib 13, and the fish belly is separated from the rib 13, and then the fish belly is cut off from the whole piece of fish.

[0017] 2) Strip the back meat of the fish along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com