Baffle plate in stirring tank

A stirring tank and baffle technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., to achieve the effects of improving mixing efficiency, reducing energy consumption of baffles, and eliminating over-baffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

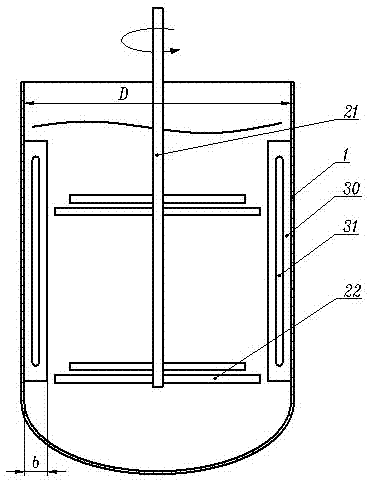

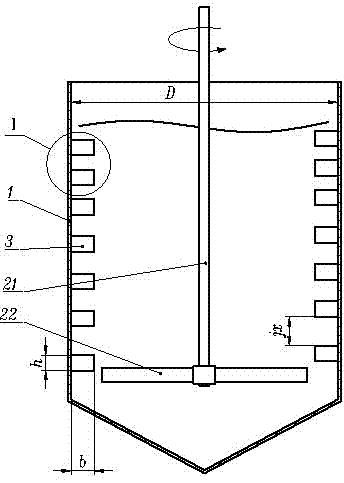

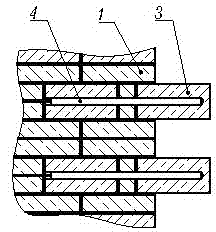

[0010] A baffle in a stirring tank (refer to figure 2 ), the baffles are arranged on the inner wall of the stirring tank 1 in the form of being evenly distributed in two to four places, and are parallel to the rotating shaft 21 of the stirring paddle in the stirring tank 1; the width of each baffle b Both are the inner diameter of the stirring tank D 1 / 12~1 / 10 of that. In the present invention, each baffle is a baffle group formed by several small baffles 3 with gaps between them; the height of each small baffle 3 h for its width b 1 / 2~2 / 3 of , the gap between two adjacent small baffles 3 jx 3 heights for small baffles h 1 to 2 times of that.

[0011] So far, those skilled in the art combined with the understanding of the principles of the beneficial effects of the present invention, have been able to manufacture the baffles in the stirring tank that are substantially the same as the present invention according to other different conditions and / or requirements.

[0012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com