Supersonic velocity spray pipe with shared throat part and design method of supersonic velocity spray pipe

A design method and supersonic technology, applied in the direction of injection device, injection device, etc., can solve the problems that the flow field quality of supersonic/hypersonic nozzle can not meet the test requirements well, and it is difficult to generate flow field test conditions with different parameters, etc. Achieve the effect of saving processing costs, improving quality and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0047] In the present invention, the subsonic section refers to the part where the flow velocity of the airflow is less than the speed of sound after entering the constriction section of the nozzle, and the subsonic section is also the transonic section, which refers to the junction between the airflow entering the supersonic state from the subsonic state, Generally, the Mach number in the subsonic section is less than 0.8, the Mach number in the subsonic section is between 0.8 and 1.2, and the Mach number in the supersonic section is greater than 1.2.

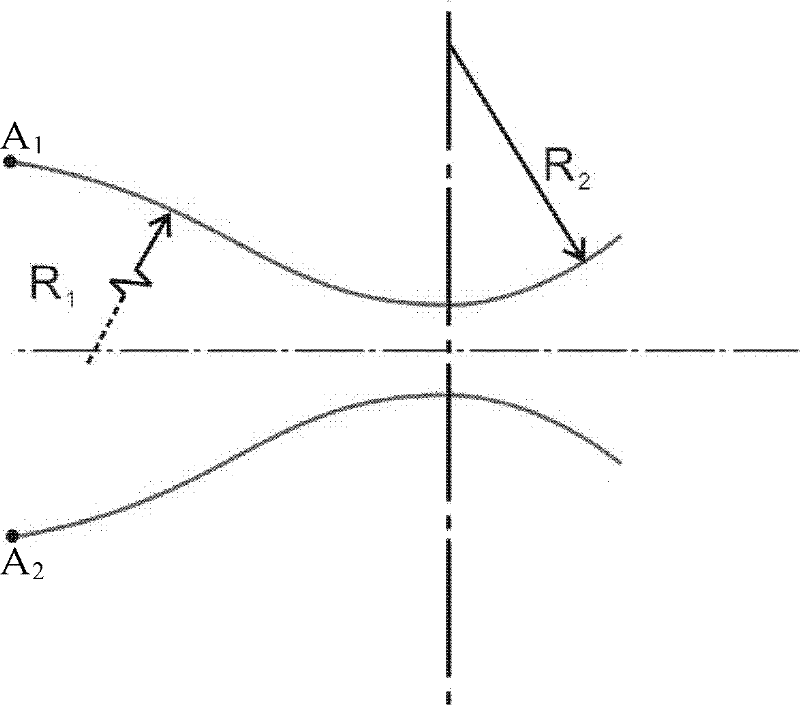

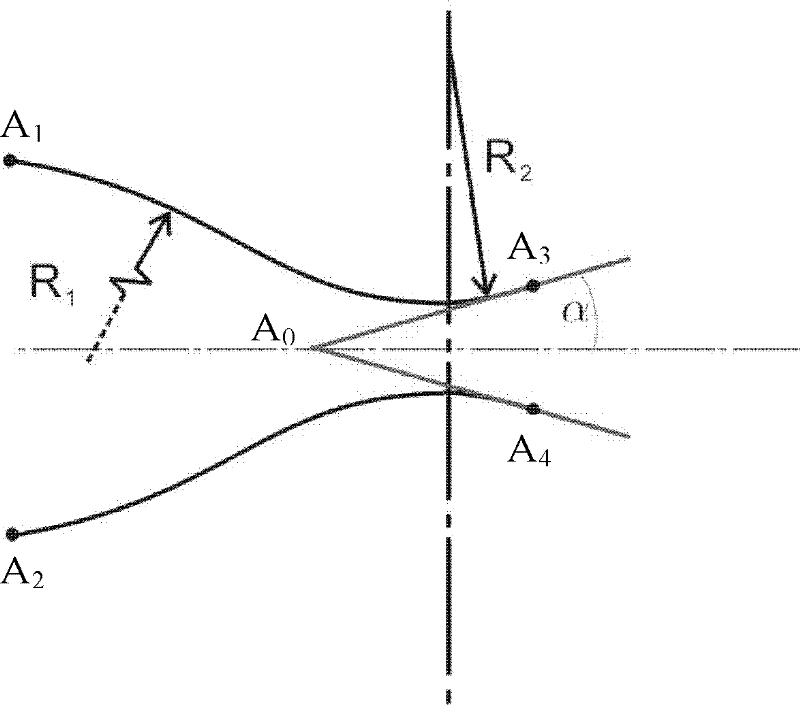

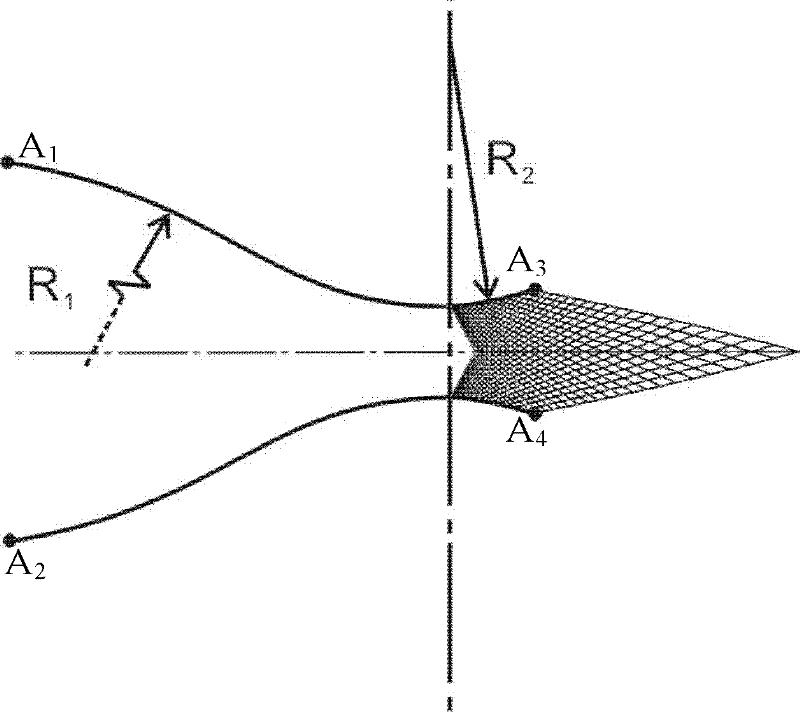

[0048] Such as figure 1 As shown, according to the supersonic nozzle design method of the shared throat of the present invention, firstly, accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com