Dustproof elevating device and concrete production apparatus comprising same

A technology of dust-proof device and production equipment, which is applied in hoisting device, clay preparation device, cement mixing device, etc., can solve the problems of inconspicuous dust collection effect of hoist, pollution of main building environment, guide rail, and dust accumulation at the feed port of main engine. , to achieve better dustproof effect and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

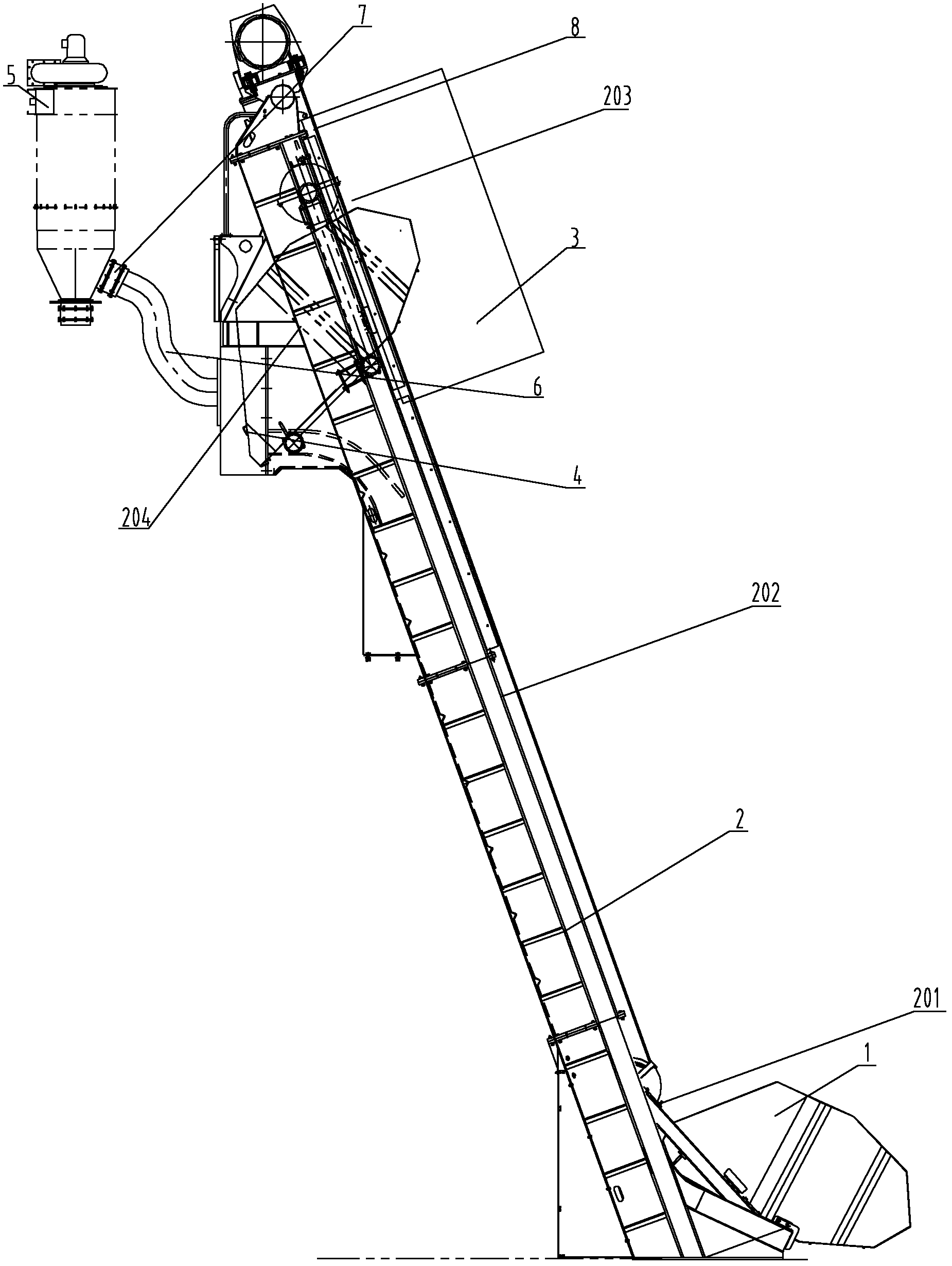

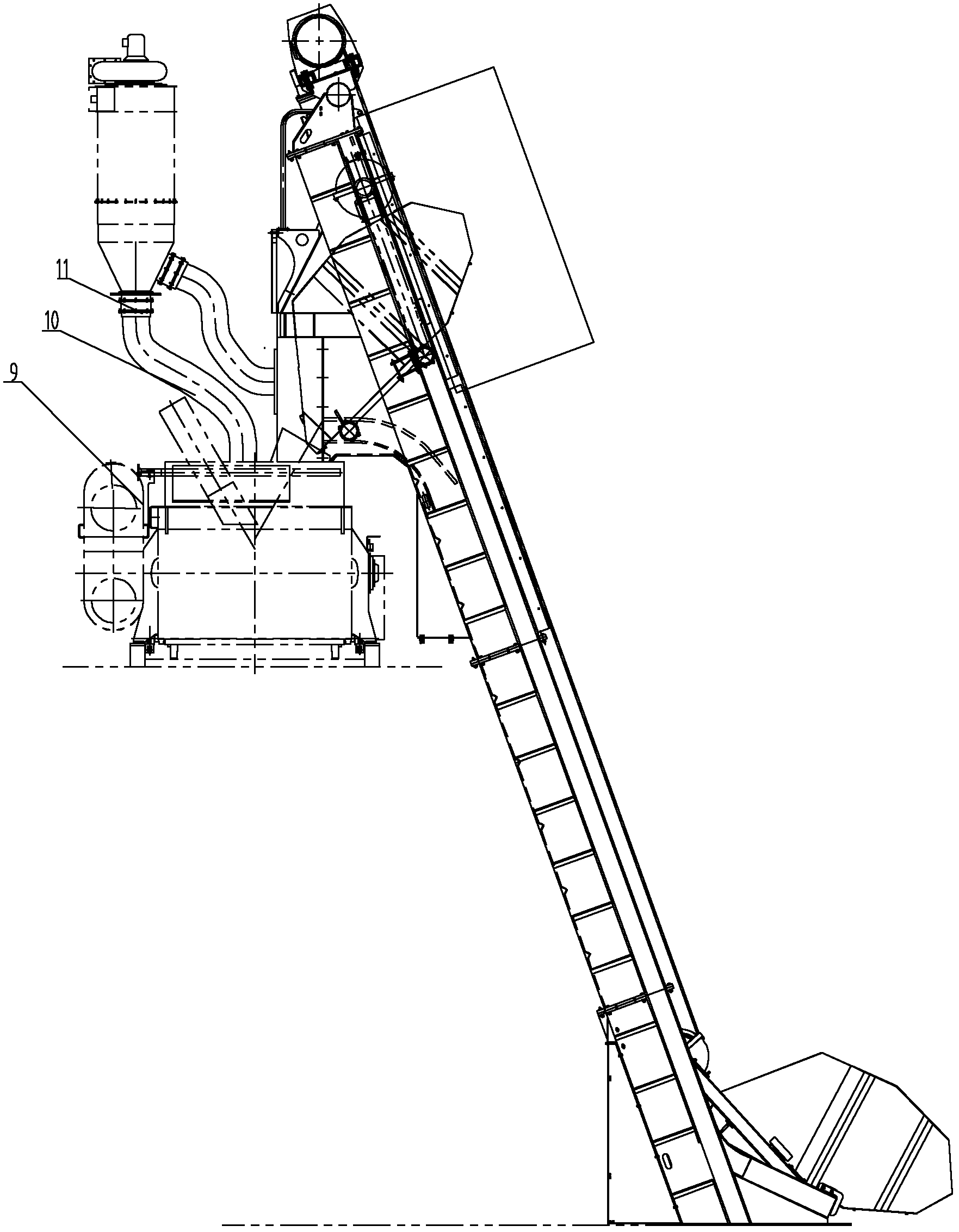

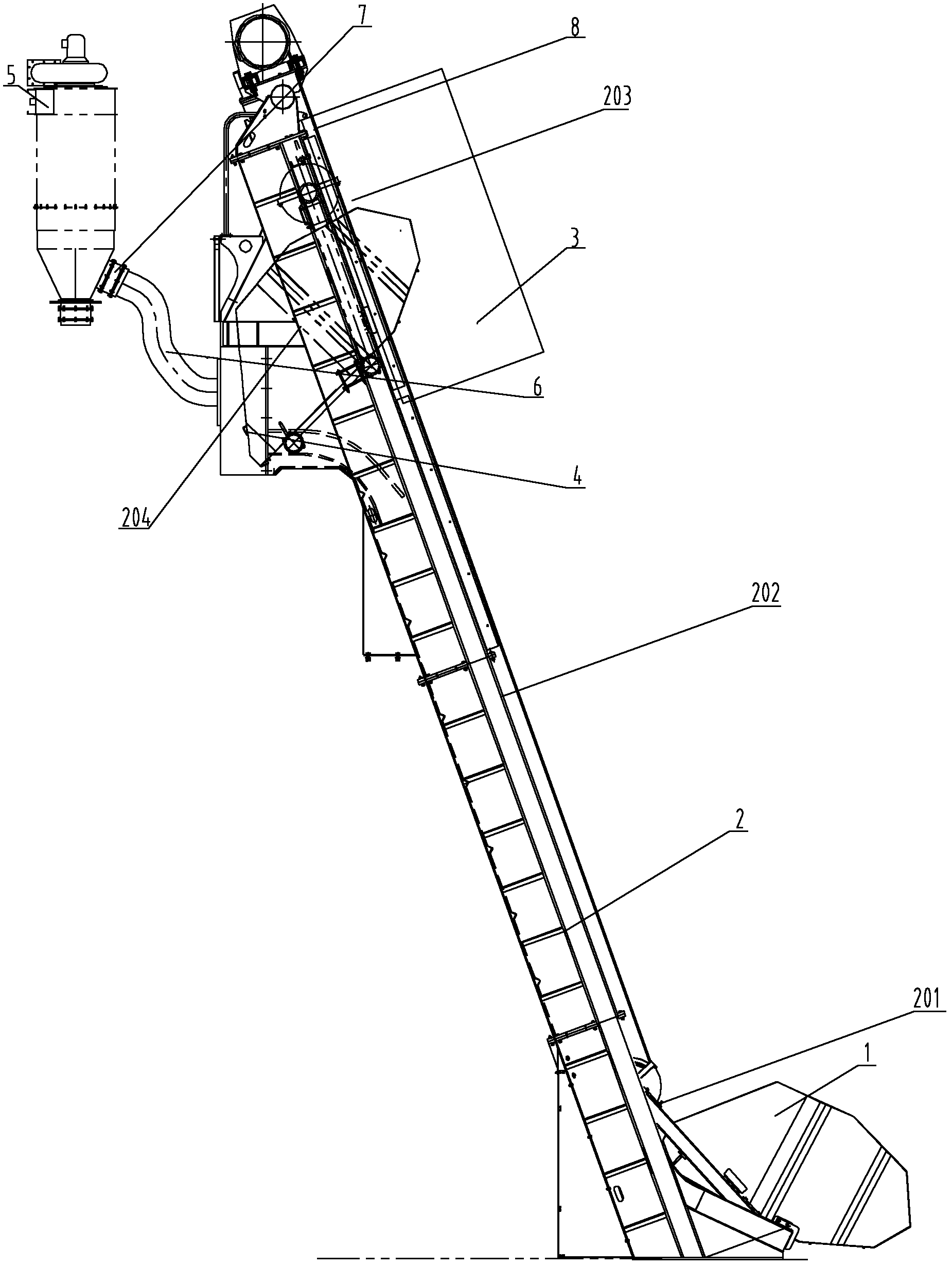

[0028] like figure 1 As shown, the dust-proof lifting device of the present invention includes: a lifting bucket 1, a lifting track 2, a dust-proof device 3, a second dust-proof device 4, a dust collector 5, a bellows 6, a pneumatic butterfly valve 7, and an induction switch 8. The lifting track 2 is divided into four areas: the lifting bucket feeding area 201 , the lifting bucket lifting area 202 , the lifting bucket turning area 203 and the lifting bucket discharge port area 204 .

[0029] The lifting bucket 1 is lifted in the lifting bucket feeding area 201, then lifted in the lifting bucket lifting area 202, lifted to the lifting bucket turning area 203, and then turned over to the lifting bucket discharge opening area 204 for discharging. As a preferred embodiment of the present invention, the dust-proof device 3 is arranged in the turning area 203 of the lifting bucket, because more dust will be generated when the lifting bucket is turned over, and the dust-proof effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com