Multielement Mg-based amorphous alloy

An amorphous alloy and amorphous technology, which is applied in the field of multi-component Mg-based amorphous alloys, can solve the problems of unpublished patents and high prices of Y elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

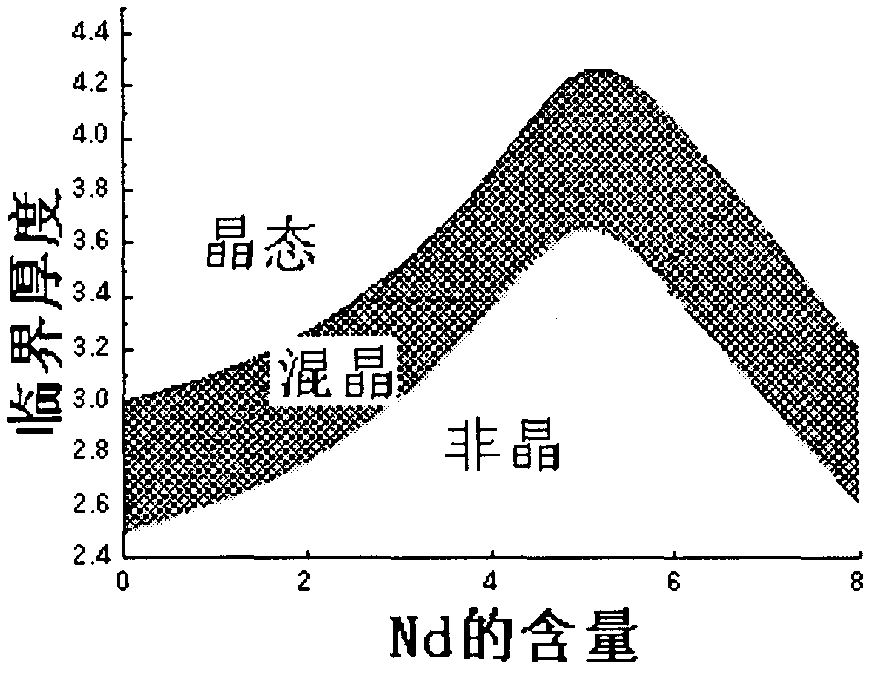

[0009] After the same smelting method as in Comparative Example 1, Mg can be obtained by adding Nd (99.95%) to replace part Y 65 Cu 22 Ni 3 Y 8 Nd 2 amorphous alloy. The critical thickness for amorphous formation is 2.6 mm, which is higher than that of Mg 65 Cu 22 Ni 3 Y 10 The critical thickness of amorphous alloys is comparable. However, the thermal stability of these two amorphous alloys is completely different. Supercooled liquid region ΔT x Indicates the tendency of devitrification of the amorphous alloy after it is heated above the glass transition point, and is an important index to measure the thermal stability of the amorphous alloy, ΔT x The larger the value, the better the thermal stability of the amorphous alloy. in Mg 65 Cu 22 Ni 3 Y 10-x Nd x (x=0, 2, 4, 5, 6, 8) In the amorphous alloy, the amorphous alloy Mg 65 Cu 22 Ni 3 Y 8 Nd 2 ΔT x Maximum, up to 61.5, amorphous alloy Mg 65 Cu 22 Ni 3 Y 10 ΔT x is 57.6. Therefore, the amorphous al...

Embodiment 2

[0011] After the same smelting method as in Comparative Example 1, Mg can be obtained by adding Nd (99.95%) to replace part Y 65 Cu 22 Ni 3 Y 5 Nd 5 amorphous alloy. The critical thickness of amorphous formation is 3.6 mm, reaching the maximum value, and the thickness is much larger than that of Mg 65 Cu 22 Ni 3 Y 10 The critical thickness of amorphous alloy, but its thermal stability is better than that of Mg 65 Cu 22 Ni 3 Y 8 Nd 2 Worse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com