A kind of smelting process of master alloy containing phosphorus and carbon

A master alloy and process technology, which is applied in the field of master alloy smelting technology, can solve the problems such as difficult to obtain master alloy, and achieve the effect of excellent amorphous forming performance, good amorphous forming ability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

[0049] This example uses factory-produced raw materials.

[0050] Add low-carbon steel, industrial FeB, and pig iron together into an electric arc furnace for melting to form the first pre-alloyed molten liquid, wherein the mass ratio of low-carbon steel, industrial FeB, and pig iron is 12.8:1:2.3, and the melting temperature is 1450 ℃ or so. Then remove S, Al, Ti, Zr impurities from the first pre-alloyed molten liquid.

[0051] The industrial FeP is refined to reduce the contents of Mn and S to obtain refined FeP. The refined FeP is mixed with the first pre-alloyed molten liquid after removing impurities according to the mass ratio of 8.6:100, and the alloy is melted in an electric furnace. The melting temperature is about 1250°C. During the smelting process, argon is blown from the bottom and vacuum is drawn from the top, so as to reduce the gas content in the second pre-alloyed molten liquid and make the second pre-alloyed molten liquid more uniform.

[0052] After the ...

Embodiment (2

[0056] This example uses factory-produced raw materials.

[0057] Add industrial pure Fe, industrial FeB, and graphite together into an electric arc furnace for melting to form the first pre-alloyed molten liquid, wherein the mass ratio of industrial pure Fe, industrial FeB, and graphite is 316:53.4:1, and the melting temperature is 1470 ℃.

[0058] The industrial FeP is mixed with the first pre-alloyed melt at a mass ratio of 1:11, and the alloy is smelted in a high-frequency induction furnace under the protection of vacuum argon. The melting temperature is about 1260°C.

[0059] After smelting evenly, pour it into a suitable mold and cool it into a master alloy ingot.

[0060] The master alloy ingot is smelted for the second time, and after re-melting, it is sprayed onto the high-speed rotating copper roller through the two-pack or three-pack method to obtain the alloy strip.

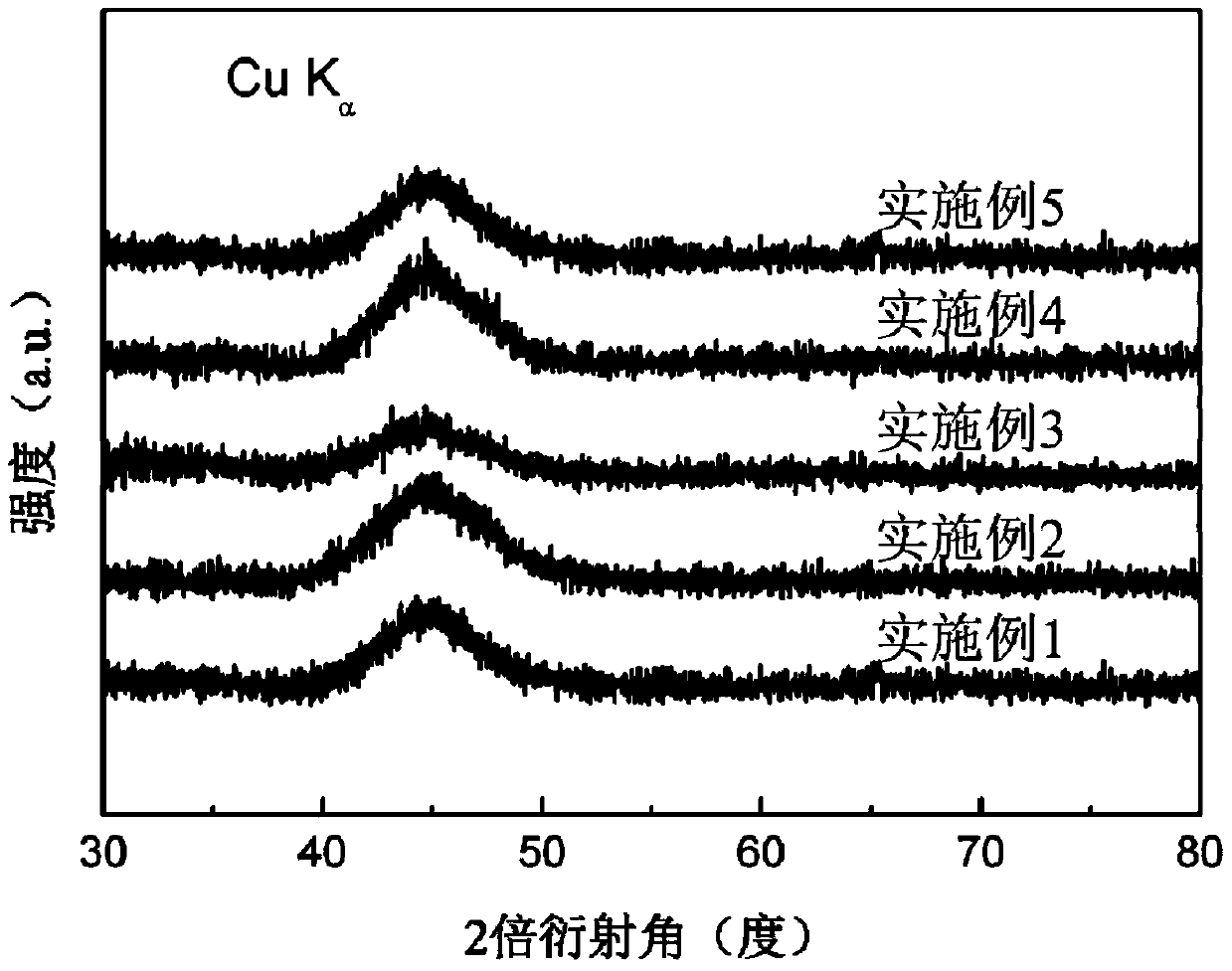

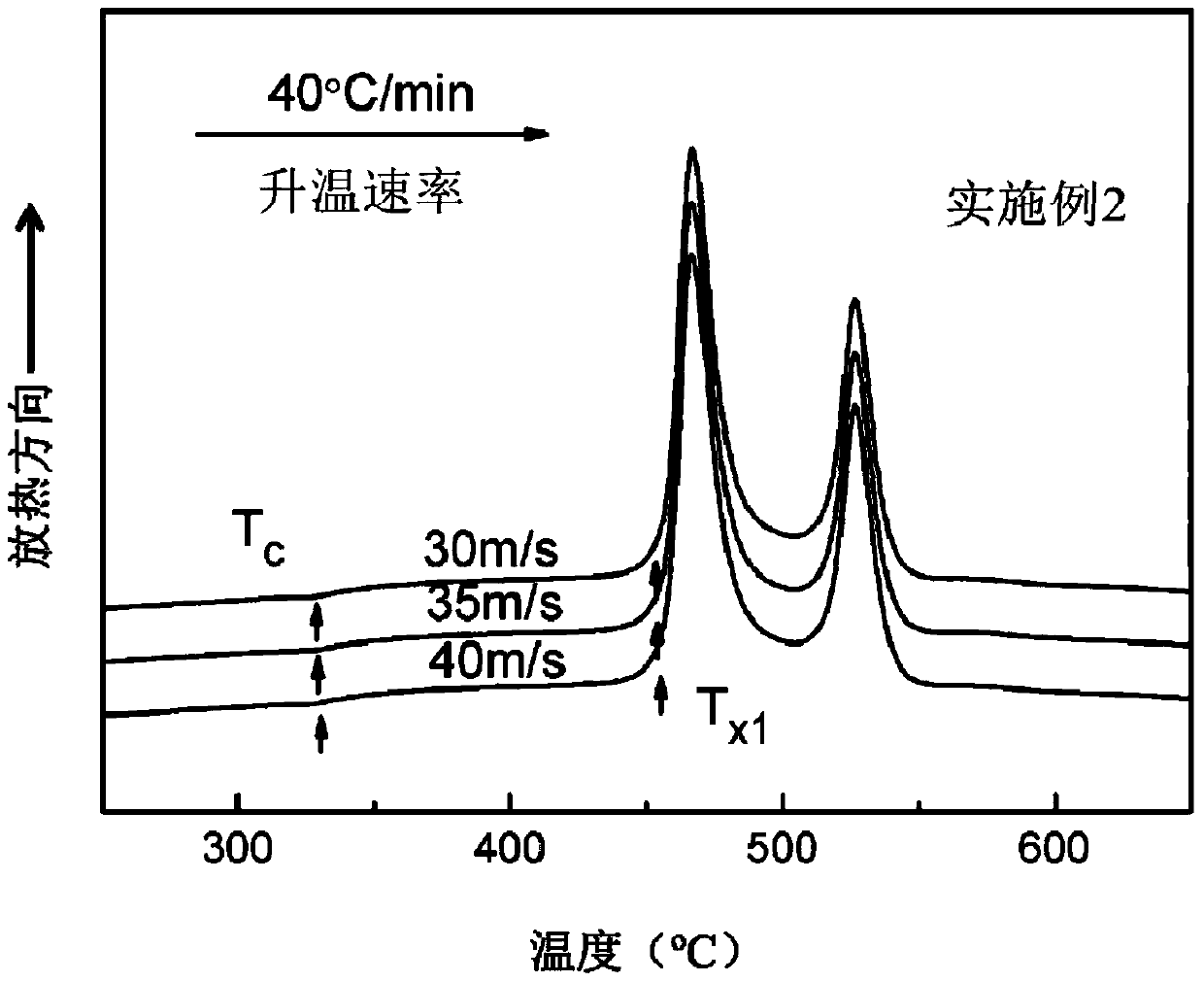

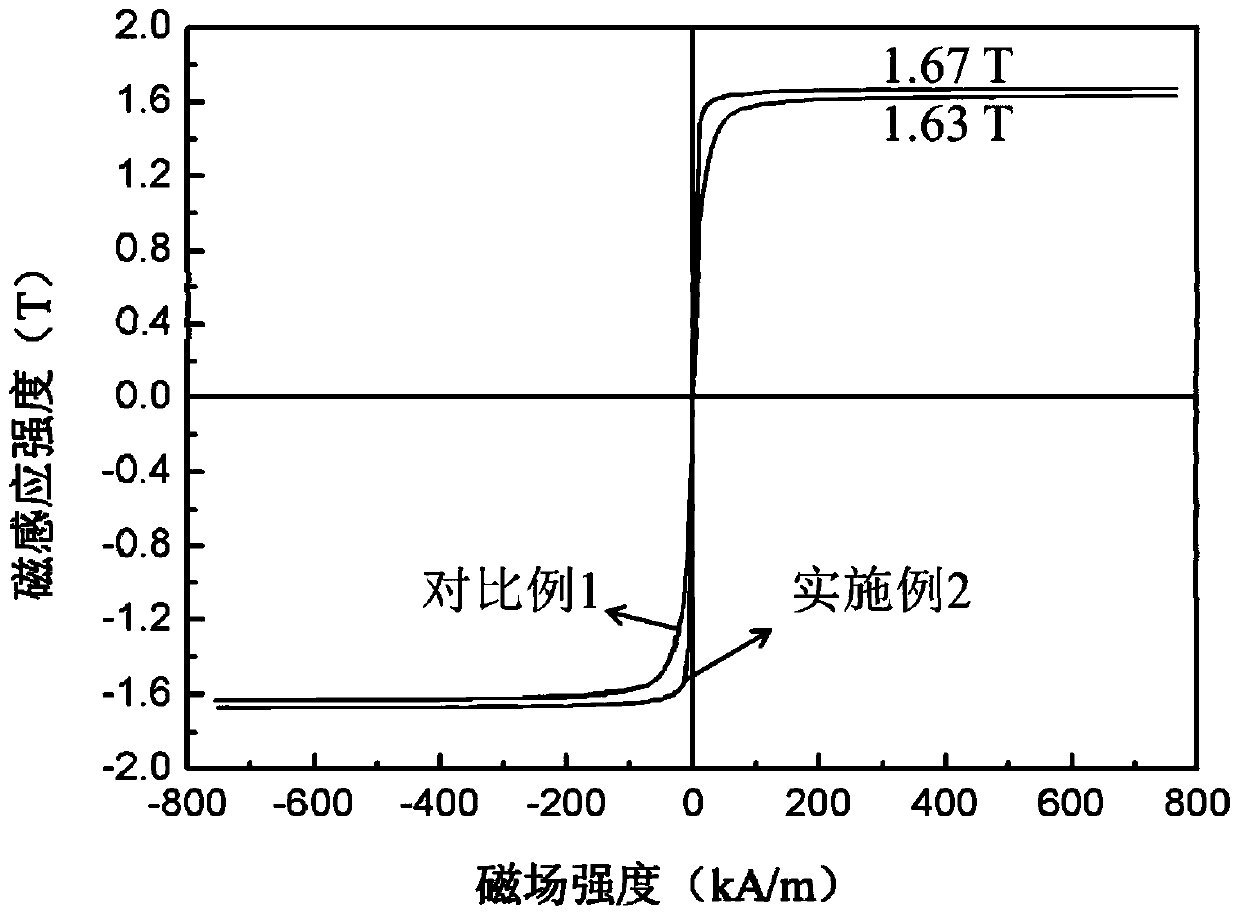

[0061] Performance tests were performed on the obtained alloy strip. Specifically, X-ray diffr...

Embodiment (3

[0063] This example uses factory-produced raw materials.

[0064] Add industrial pure Fe and medium-high carbon steel together into the electric arc furnace for melting to form the first pre-alloyed molten liquid, in which the mass ratio of industrial pure Fe and medium-high carbon steel is 1.56:1, and the melting temperature is about 1600°C.

[0065] Industrial FeP, industrial FeB, and Si are pre-alloyed and smelted repeatedly in an electric arc furnace to obtain a smelting mixture. Among them, the mass ratio of industrial FeP, industrial FeB, and Si is 12.7:20.1:1, and the melting temperature is about 1350°C.

[0066] The smelting mixed liquid is mixed with the first pre-alloyed molten liquid at a mass ratio of 3.6:1, and the alloy is smelted in a high-frequency induction furnace under the protection of vacuum argon. The melting temperature is 1260°C.

[0067] After smelting evenly, pour it into a suitable mold and cool it into a master alloy ingot. The master alloy is sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com