A zirconium-based amorphous alloy and its preparation method

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of zirconium-based amorphous alloy material and its preparation, can solve the problems of high manufacturing cost, difficult post-processing procedures of amorphous alloy products, improved amorphous forming ability, and the like, Achieve the effect of reducing the cost of raw materials, compact structure, and good amorphous forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1. Embodiment of the present invention

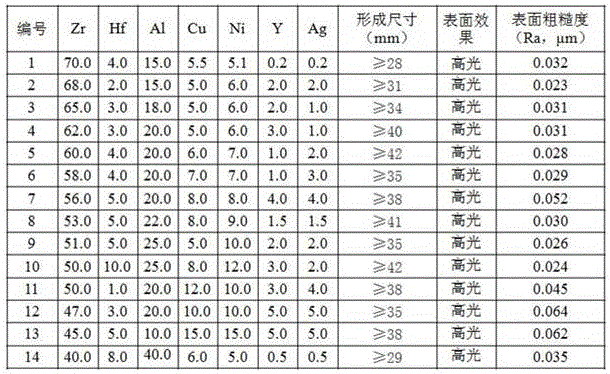

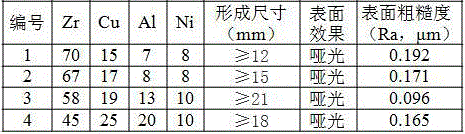

[0033] The preparation method of the zirconium-based amorphous alloy product of the present invention is as follows: the amorphous raw materials are smelted under vacuum conditions or in an argon atmosphere according to the proportion, and the vacuum degree is 10 -1 -10 -2 Any pressure within the Pa range is acceptable. If the argon atmosphere is selected, the argon pressure can be adjusted within the range of 0.01-0.1 MPa, preferably 0.05-0.08 MPa. As long as the vacuum degree or argon pressure is within the range, the melting effect can be guaranteed. Cooldown rate is set to 10 2 -10 3 K / s can be used without any significant effect. The raw materials of Zr and Hf are selected from zircon raw ore dressing and smelting without removing Hf. The common purity of Zr and Hf in this product can reach more than 99.9%; the purity of Al, Cu, Ni, Y and Ag metal raw materials is selected as More than 99.9%.

[0034] After smelting a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com