Polar plate drying equipment

A technology for drying equipment and plates, applied in progressive dryers, drying solid materials, lighting and heating equipment, etc., can solve problems such as increased rework rate, unqualified plates, and operators are prone to occupational diseases, etc., to improve Effect of drying efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

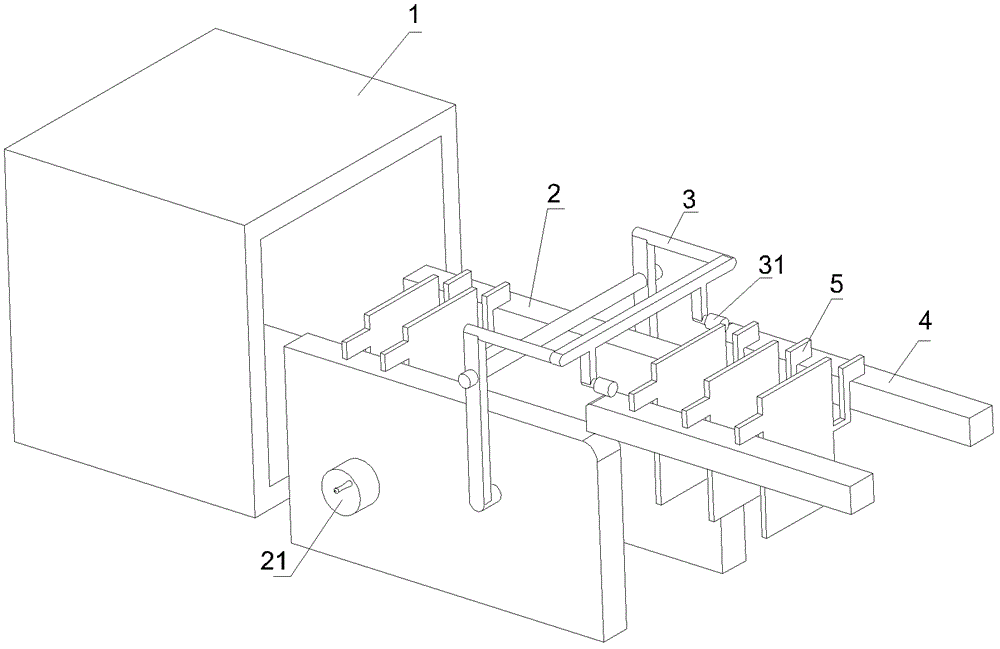

[0021] Please refer to figure 1 , a kind of pole plate drying equipment of the present invention, comprises the oven 1 that is used for drying process to pole plate 5, the transmission device that is connected with the input end of oven 1, is used for the upper plate rack of input pole plate 5 and is used for automatically The pole plate 5 is separated from the upper plate frame and sequentially transported to the plate suction machine 3 of the conveying device, and the oven is a circulating hot air oven.

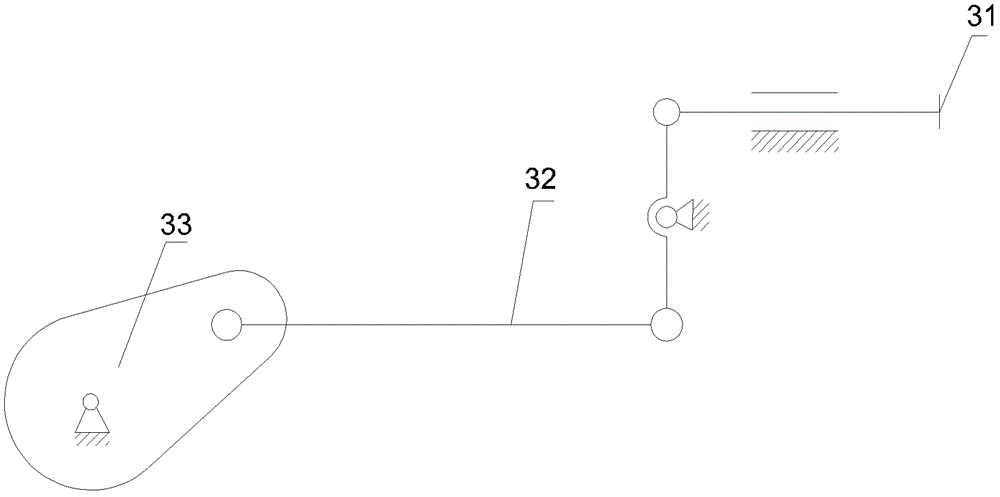

[0022] The plate suction machine 3 includes a machine base, a driving mechanism capable of outputting reciprocating motion, a suction nozzle 31 for suctioning the electrode plate 5 and an air pipe communicating with the suction nozzle 31 . Please refer to figure 2 , the drive mechanism includes a motor forming a cam linkage mechanism, a cam 33 and a transmission rod 32, the motor is fixed on the base, the output end of the motor is fixedly connected to the cam 33, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com