Method and equipment for detecting appearance quality of product

A technology of appearance quality and detection method, applied in the direction of optical testing defect/defect, sorting, etc., can solve the problems of product detection and rejection on the production line that cannot be automated, and achieve the effect of high degree of equipment automation, clear imaging, and comprehensive detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

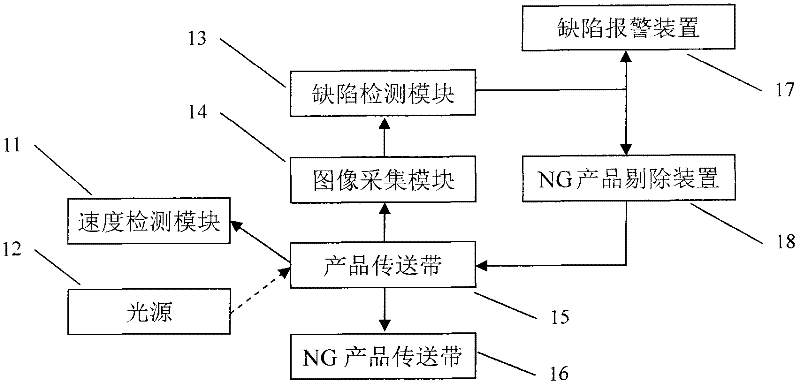

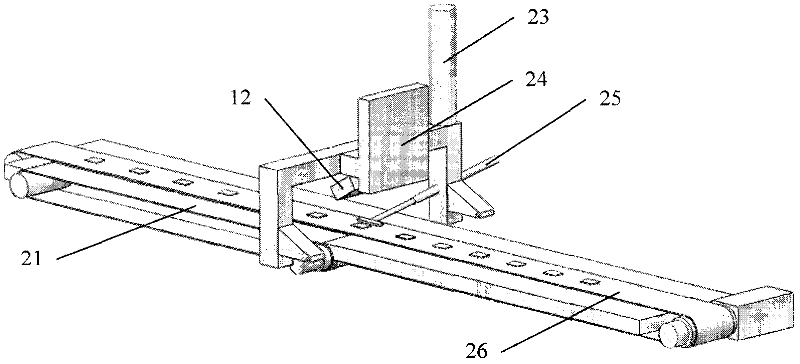

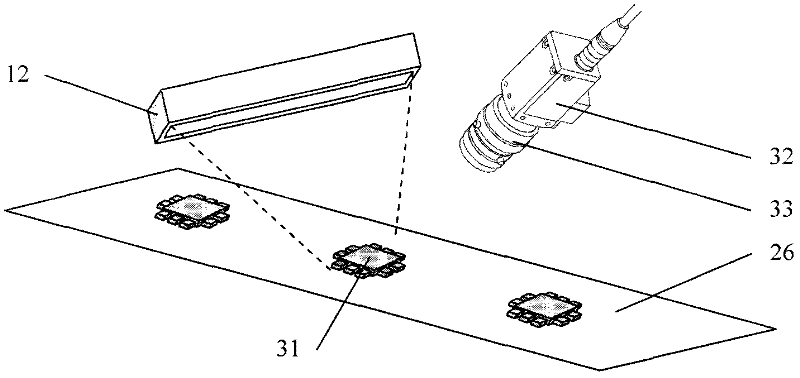

[0035] figure 1 A schematic flow chart of the automatic product appearance quality detection method of the present invention is given, the method involves: a light source 12, a speed detection module 11, an image acquisition module 14, a defect detection module 13, a defect alarm device 17, an NG product rejection device 18, Product conveyor belt 15, NG product conveyor belt 16. Wherein, the image acquisition module 14 is fixed above the product conveyor belt 15, and is connected with the defect detection module 13; the defect alarm device 17 is connected with the defect detection module 13; NG product conveyor belt 16 is connected with product conveyor belt 15; light source 12 is relatively fixed with product conveyor belt 15; speed detection module 11 is connected with product conveyor belt 15.

[0036] The light source 11 provides uniform, consistent illumination to the product being inspected. This embodiment adopts a strip-shaped green LED light source with a wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com