Flat panel detector for X rays

An X-ray and detector technology, which is applied in the field of flat-panel X-ray detector exposure control and X-ray detector, can solve the problems of increasing the complexity of the flat-panel X-ray detector manufacturing process and increasing the manufacturing cost of the flat-panel X-ray detector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

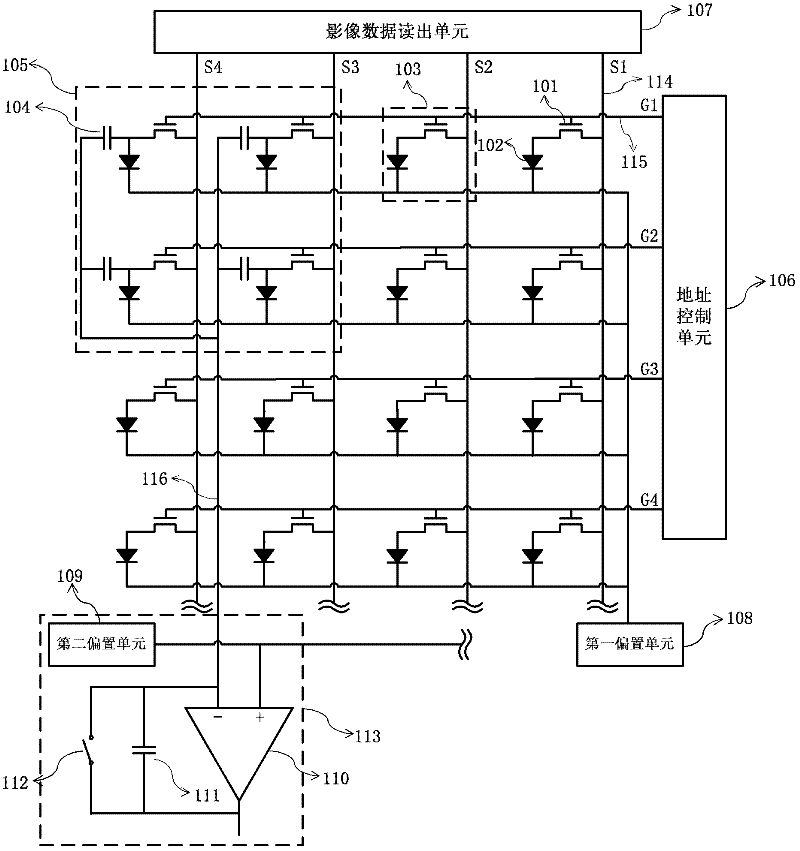

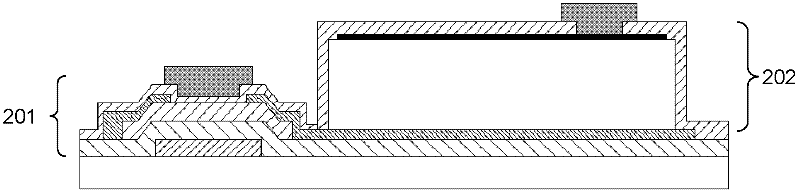

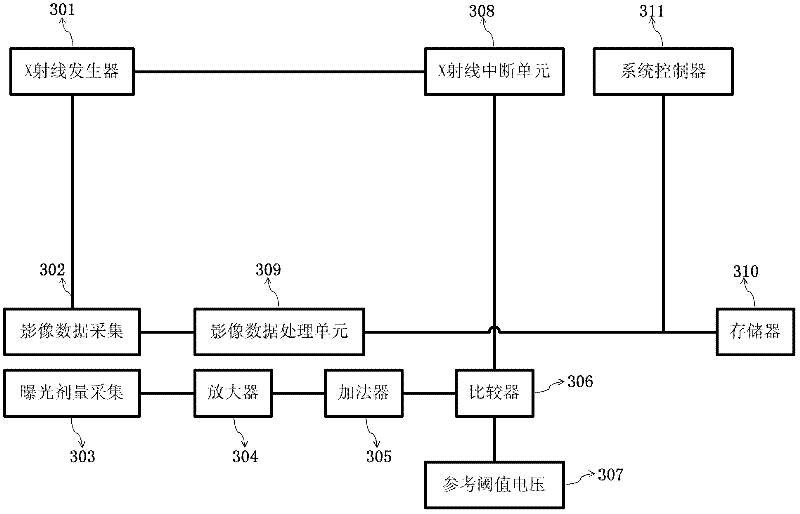

[0044] The technical solution of the present invention is to use the metal electrode fabricated at the same time as the underlying gate metal to form a capacitor with the lower electrode of the photodiode, and generate an image charge equivalent to the image data charge stored in the photodiode on the electrode of the capacitor through the coupling of the capacitor , and then through the exposure dose detection readout unit to read out the image charge on the underlying gate metal, and after further processing, an interrupt signal is formed to control the end of the X-ray exposure. In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] In order to better understand the technical solution of the present invention, firstly, the working principle of the X-ray detector of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com