Image sensor and forming method thereof

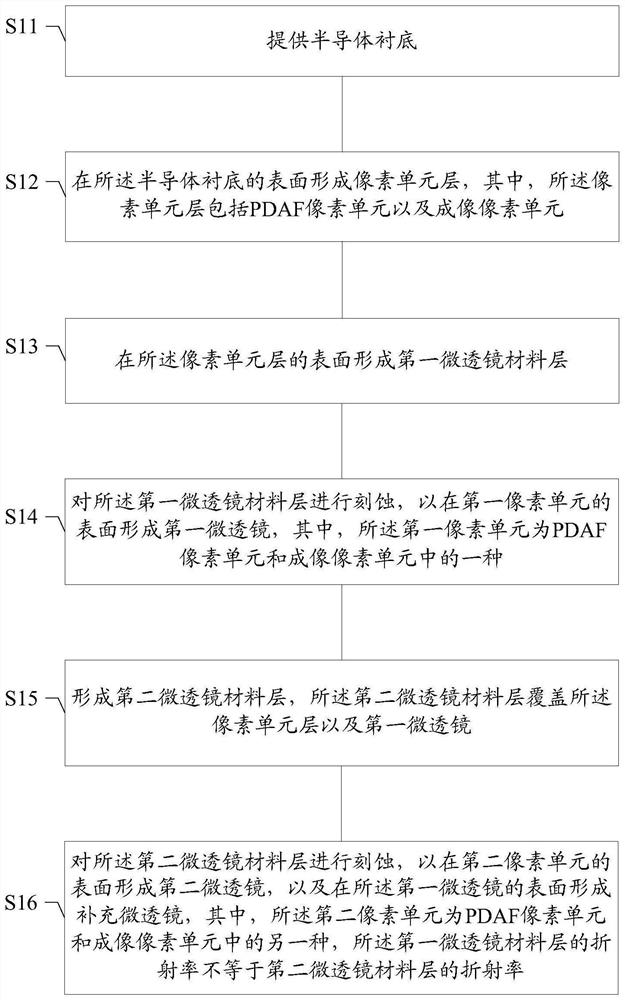

An image sensor and graphic technology, applied in radiation control devices, etc., can solve problems such as abnormal imaging of imaging pixel units and deformation of microlens shapes, and achieve the effects of avoiding damage, improving imaging quality, and realizing PDAF and imaging functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

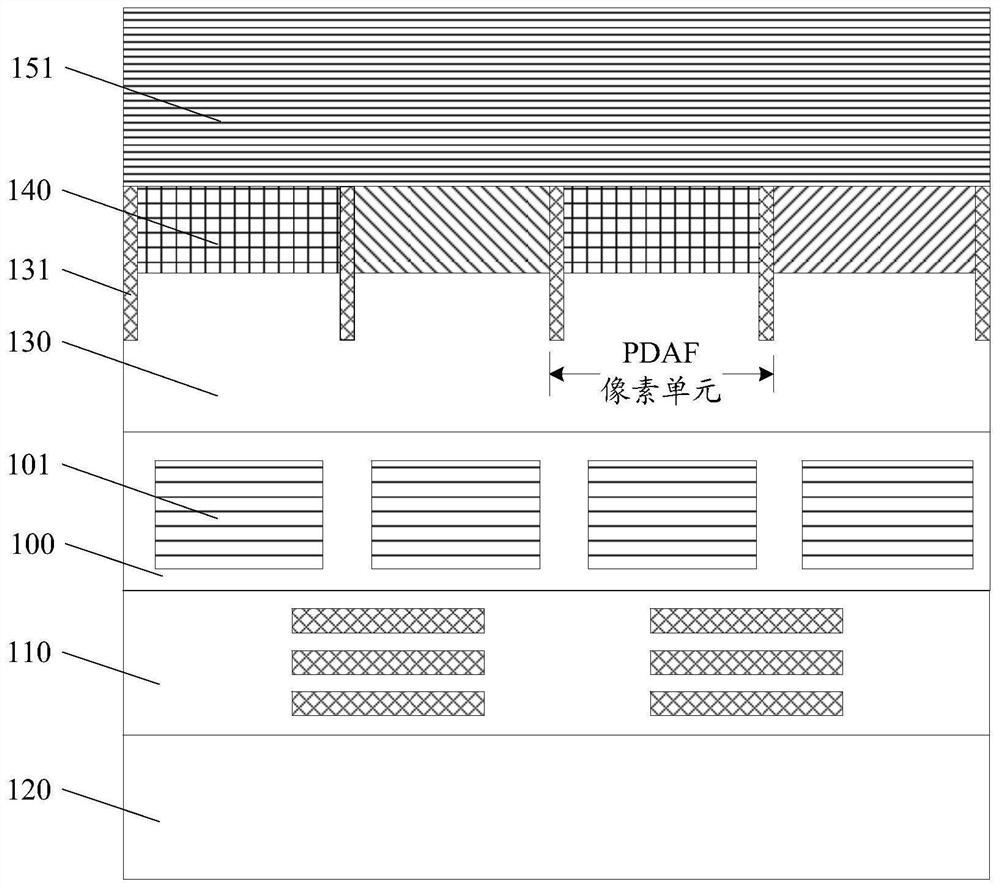

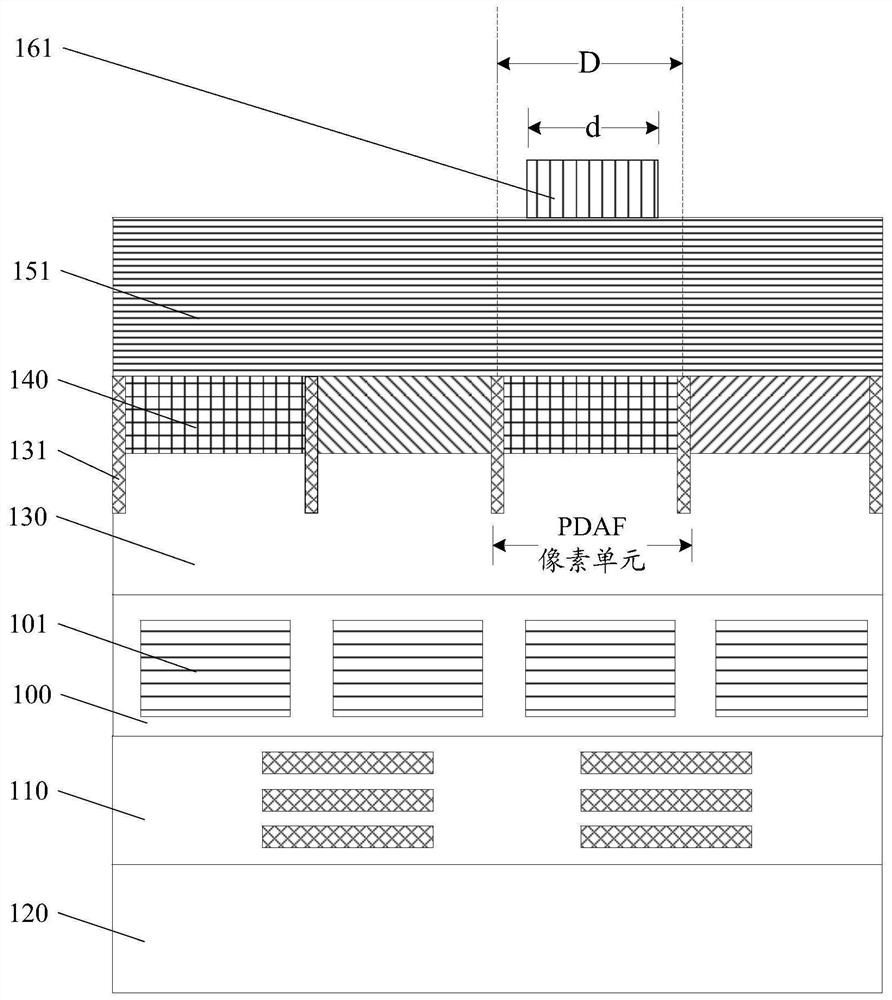

[0027] As mentioned above, in the prior art, in order to improve the performance of the optical image sensor, the PDAF technology is used for focusing. Lenses, different microlens curvatures can be used. For example, the surface of the microlens on which the PDAF pixel unit is arranged has a higher degree of curvature and a larger curvature.

[0028] The inventor of the present invention has found through research that in the prior art, the PDAF function and the imaging function are realized by using different microlens curvatures, and the processes of forming different curvatures usually have an impact on the microlenses of the imaging pixel unit, resulting in PDAF pixels. The shape of the microlens of the imaging pixel unit around the unit is deformed. For example, when the surface curvature of the microlens of the PDAF pixel unit is higher, the surface curvature of the microlens of the imaging pixel unit around the PDAF pixel unit is also higher than normal. The degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com