Lithium ion power battery pack for electric automobile and manufacturing method of lithium ion power battery pack

A technology for power battery packs and electric vehicles, which is applied in the field of lithium-ion batteries, can solve the problems that the service life and safety performance of the battery pack cannot be guaranteed, the gap heat dissipation cannot achieve a good effect, and the safety requirements of automobiles cannot be met, and the invention is beneficial to The effect of heat dissipation, low cost and stable internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

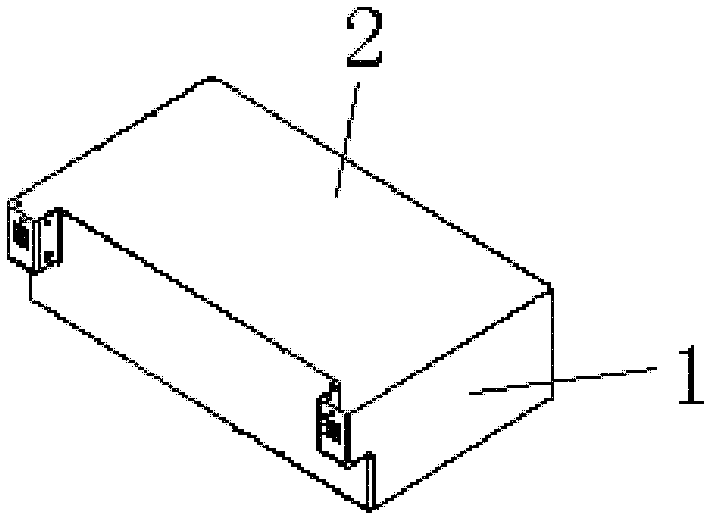

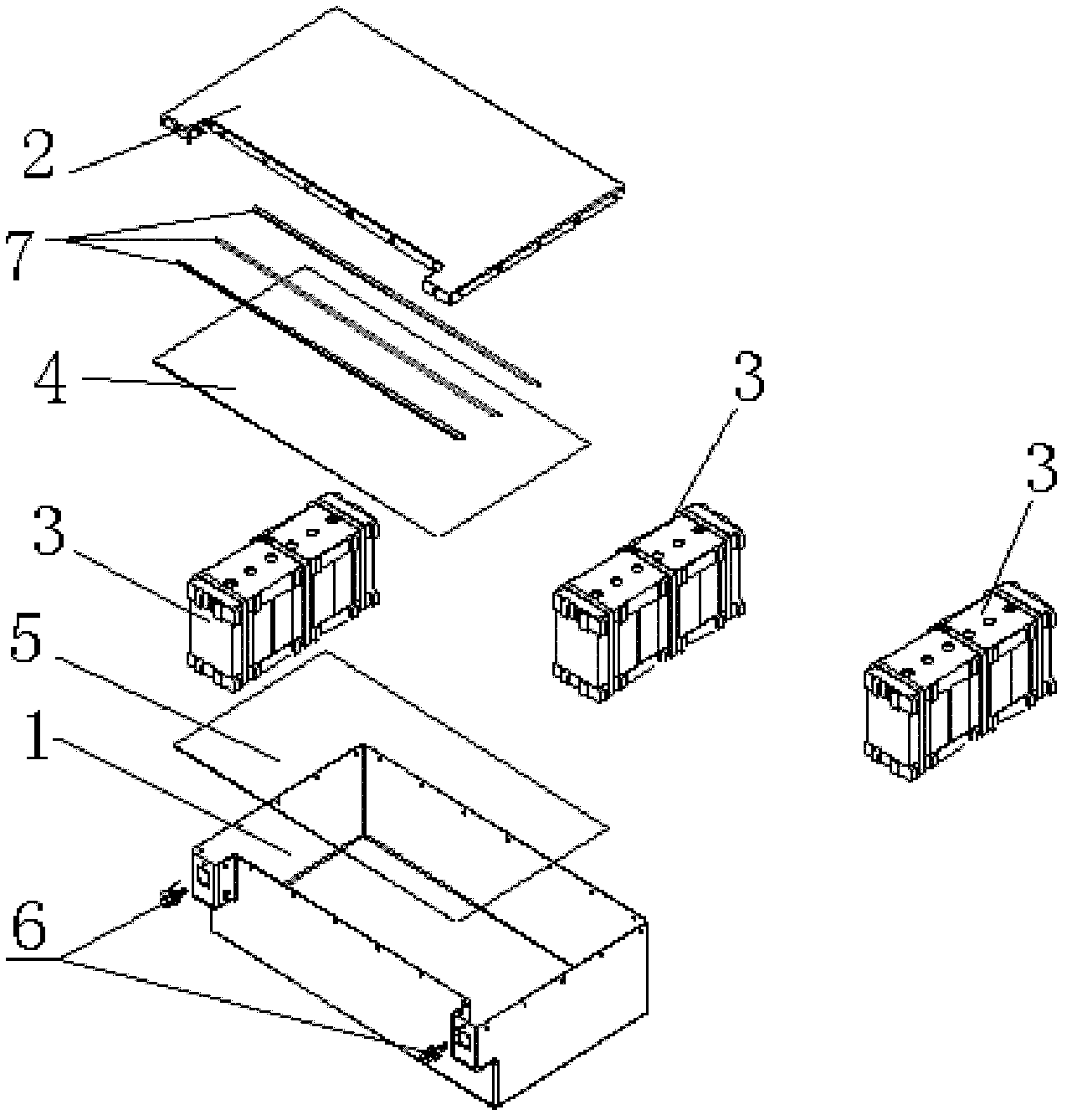

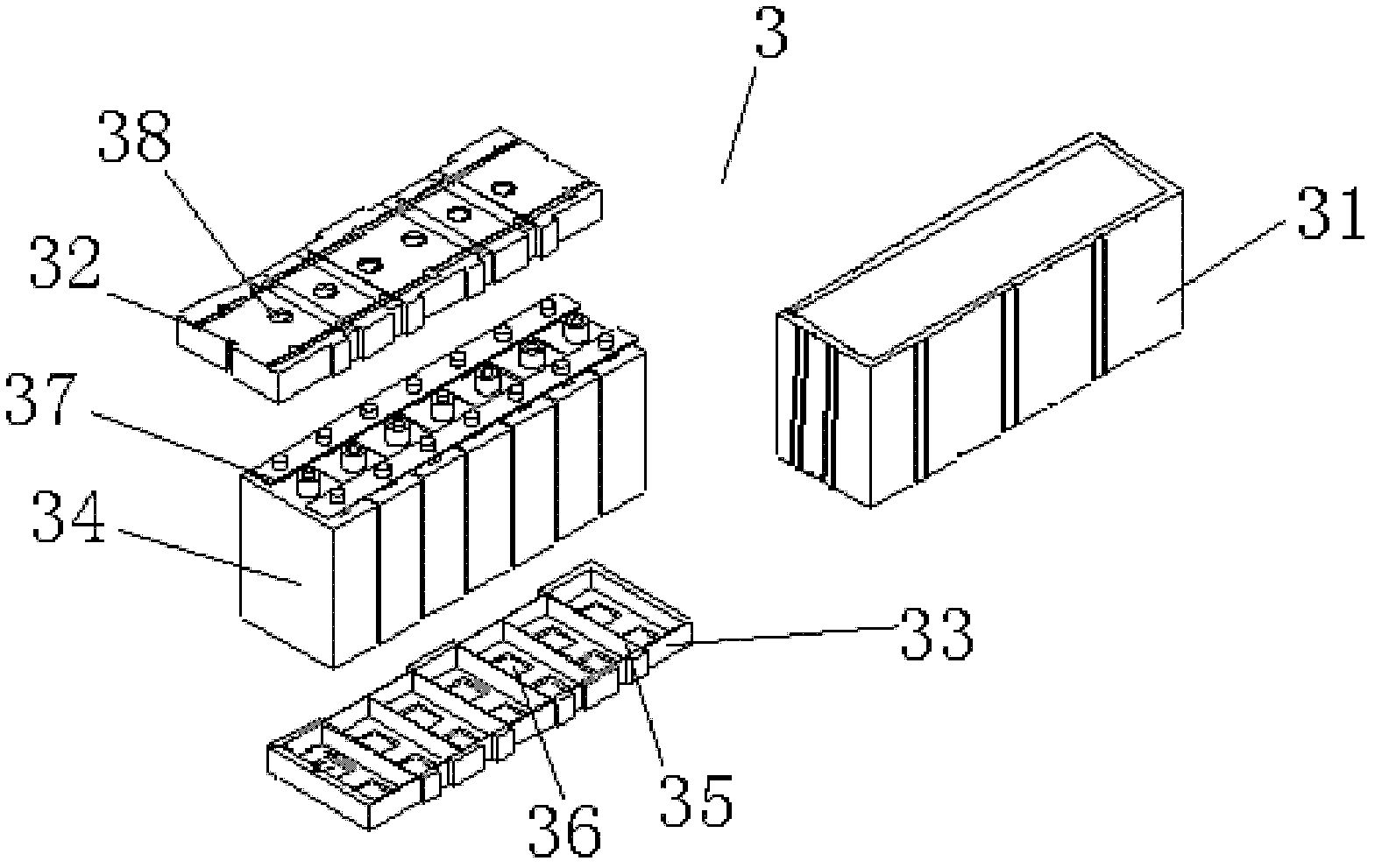

[0042] Such as Figure 1 to Figure 6 As shown, the lithium-ion power battery pack for electric vehicles includes a battery pack case 1 and a battery pack cover 2 adapted to the battery pack case 1, and a battery module 3 is provided inside the battery pack case 1; An insulating layer I 4 is provided between the battery module 3 and the battery pack cover 2, and an insulating layer II 5 is provided between the battery pack shell 1 surface facing the battery pack cover 2 and the battery module 3; the battery pack shell 1 is provided with The quick connector 6 connected to the battery module 3 is engaged with the adjacent battery modules 3 inside the battery pack housing 1 .

[0043] In the lithium-ion power battery pack for electric vehicles, the adjacent battery modules 3 located inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com