Lithium ion electrical core and lug

A lithium-ion battery, lithium-ion technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of high welding temperature, electrolyte vaporization, high internal resistance, etc., to reduce impedance, reduce heating temperature, increase welding area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

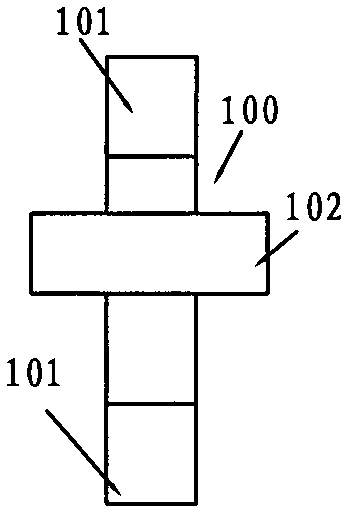

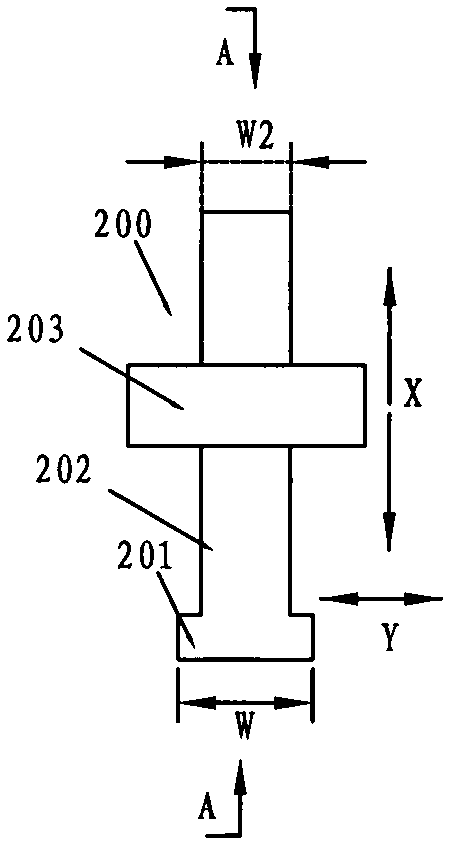

[0049] figure 2 A schematic diagram of the appearance structure of a tab 200 for a lithium ion battery provided in this embodiment. When referring to the figure, the tab 200 includes a metal strip and tab glue 203 pasted on the front and back of the metal strip, and tabs on both sides The positions of the glue 203 are facing and overlapping, and the structure of the tab 200 in this embodiment is different from the prior art mainly including:

[0050] In this embodiment, the longitudinal direction of the metal strip 202 in the tab 200 ( figure 2 One end of the end of X-axis direction) is provided with a protruding portion 201 protruding along the transverse direction of the metal strip 202, so that the width of the entire metal strip 202 at the protruding portion 201 at the two ends of the metal strip 202 is greater than that of the metal strip The width W2 of the middle part of 202 . For example: the metal belt 202 is as a whole figure 2 The "T" shape structure shown in ...

Embodiment 2

[0062] Figure 5 For the schematic diagram of another tab shape structure provided in this embodiment, see Figure 5 As shown, the tab 500 of this embodiment includes a metal strip 504 and overlapping tab glue 503 pasted on the front and back of the metal strip. The differences between the tab 500 of this embodiment and the prior art include the following:

[0063] Both ends of the metal strip 503 in this embodiment are provided with protrusions 501 , 502 as shown in Embodiment 1. see Figure 5 As shown, the two ends of the metal strip 503 respectively have a "T" self-shaped protrusion 501, 502, so that the metal strip 503 is in the shape of an "I" as a whole.

[0064] In the figure of this embodiment, the embodiment is described by taking the tab of the metal strip 504 in the shape of "I" as an example, but it is not limited thereto. For example: as described in Embodiment 1, the protrusions 501, 502 at both ends of the metal strip 504 are in the shape of a "T" at one end ...

Embodiment 3

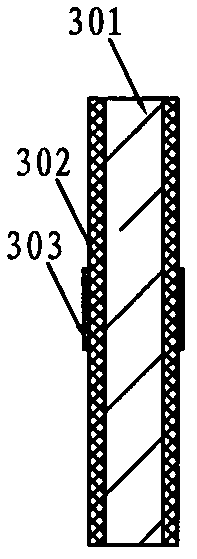

[0073] Figure 6 A schematic structural diagram of a lithium-ion battery cell provided for this implementation. The lithium ion battery cell provided in this embodiment adopts the tab 200 with the structure of Embodiment 1.

[0074] see Figure 6 As shown, the lithium-ion cell mainly includes a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte, a positive electrode tab 601 , a negative electrode tab 602 , and an aluminum-plastic packaging film 603 . Its specific structure is:

[0075] The diaphragm is spaced between each positive electrode piece and the negative electrode piece, and the positive pole tab 601 and the negative pole tab 602 are respectively welded to the tab welding part reserved on the positive pole piece and the negative pole piece, on the front side of the middle part of the metal strip of the positive pole tab 601 and the negative pole tab 602 And the opposite side is all pasted with lug glue 605 (insulating material of nylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com