Apparatus for producing Ic chip mounter

A technology for manufacturing devices and chip mounting, which is applied to record carriers, instruments, computer parts, etc. used in machines. It can solve the problems of damage, prolong the total length of the heating and pressurizing mechanism, weak impact ability, etc., and reduce friction. coefficient, improve yield, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

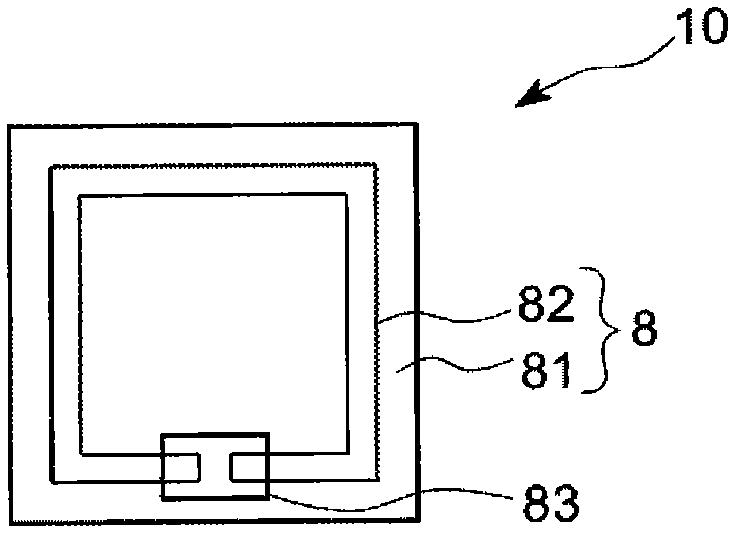

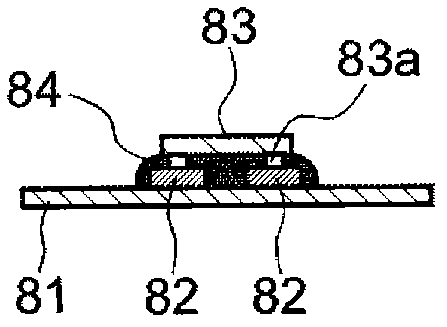

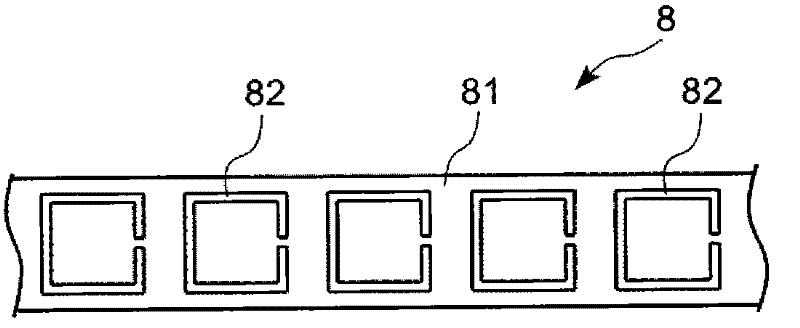

[0031]First, the IC tag 10 which is an example of the IC chip package manufactured by the manufacturing apparatus of the IC chip package of this invention is demonstrated. figure 1 It means from the IC chip package 9 (refer to Figure 4 ) is a top view of an IC tag 10 cut out, figure 2 is a schematic diagram showing a longitudinal cross-sectional view of the IC tag. The antenna circuit 82 is preformed on the substrate 81 by printing and etching, such as image 3 As shown, a plurality of antenna circuits 82 are continuously formed on the substrate 81 at intervals (for example, at equal intervals). The IC tag 10 includes a thin film substrate 8 and an IC chip 83, the thin film substrate 8 is formed with an antenna circuit 82 at a predetermined position on one surface of the substrate 81; load. Figure 4 It is a top view schematically showing the sheet-shaped IC ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com