Pleura biopsy puncture sampling brush

A technique for pleural biopsy and puncture needle, which is applied to trocars and other directions, can solve the problems of low success rate of sampling and inspection, and achieve the effects of simple structure, reasonable design and increased possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

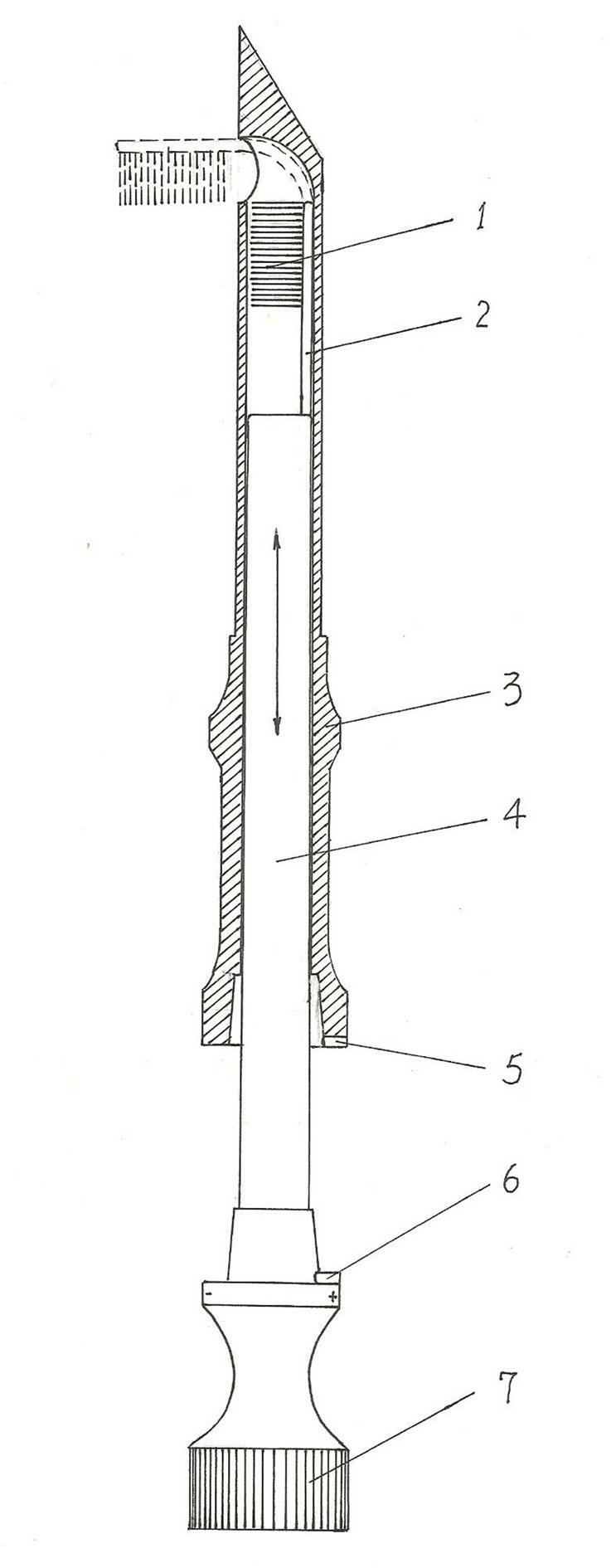

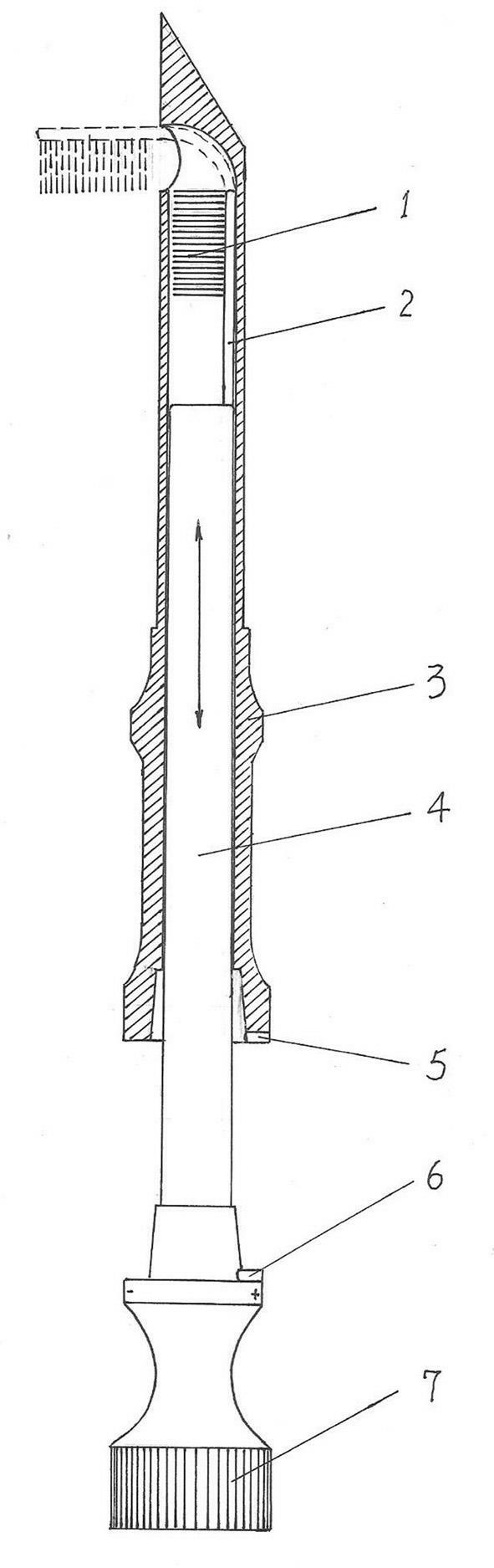

[0013] like figure 1 As shown, the present invention includes three parts: a puncture needle barrel 3 , a needle bar 4 and a brush positioned at the front end of the needle bar 4 . The front end of the puncture needle cylinder 3 is the puncture tip, and the outer periphery of the rear part is a reinforced section for easy gripping. The top opening of the core hole of the puncture needle cylinder 3 is opened at the front end of the puncture needle cylinder after being turned by not less than 90° on the side wall. Because if the steering angle is less than 90°, the protruding brush will be in an upwardly inclined posture, which is not conducive to scraping the inner wall of the pleural cavity. Therefore, it is advisable to generally control the turning angle of the top opening of the core hole of the puncture needle barrel 3 at 91-95°.

[0014] The needle bar 4 is in the shape of a round rod with a straight handle. A control handle 7 is connected to the lower end of the needle...

Embodiment 2

[0017] like figure 1 As shown, the present invention includes three parts: a puncture needle barrel 3 , a needle bar 4 and a brush positioned at the front end of the needle bar 4 . The front end of the puncture needle cylinder 3 is the puncture tip, and the outer periphery of the rear part is a reinforced section for easy gripping. The top opening of the core hole of the puncture needle cylinder 3 is opened at the front end of the puncture needle cylinder after being turned by not less than 90° on the side wall.

[0018] The needle bar 4 is in the shape of a round rod with a straight handle, and a control handle 7 is connected to the lower end of the needle bar 4, and positioning marks are engraved on the outer surface of the control handle 7 and the lower end outer surface of the puncture needle barrel 3 respectively. In addition, radial positioning marking lines are engraved on the lower part of the needle bar 4 to determine the initial position of the needle bar advance; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com