Given method for on-line detection of additional starting moment loaded mine hoist

A mine hoist, starting torque technology, applied in the direction of elevators, transportation and packaging, etc., can solve problems such as inversion, achieve the effect of avoiding inversion, solving delay problems, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

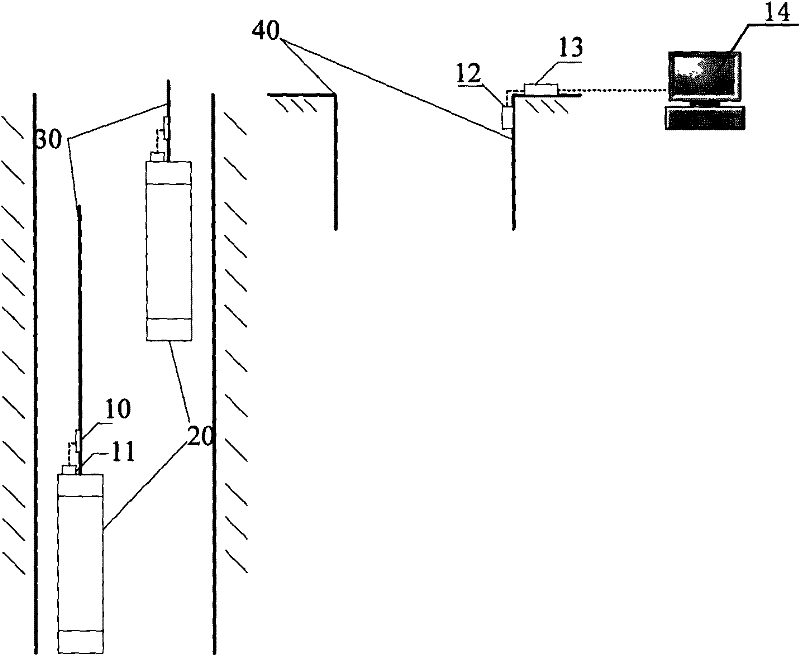

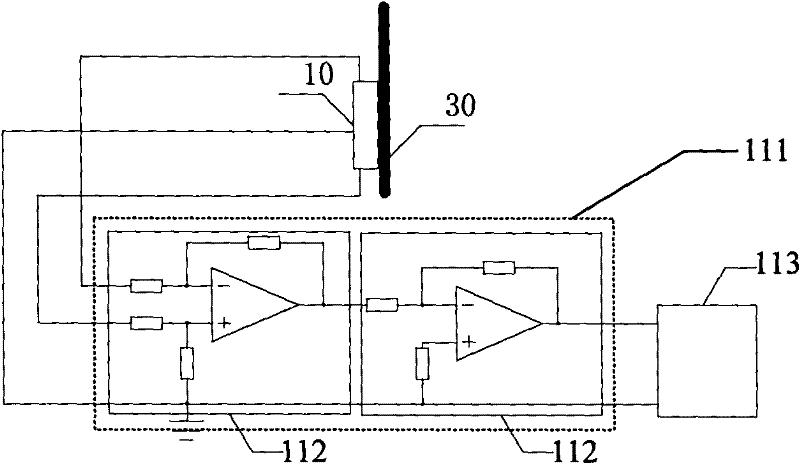

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] The following examples are implemented on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are provided, but the protection scope of the present invention is not limited to the following examples.

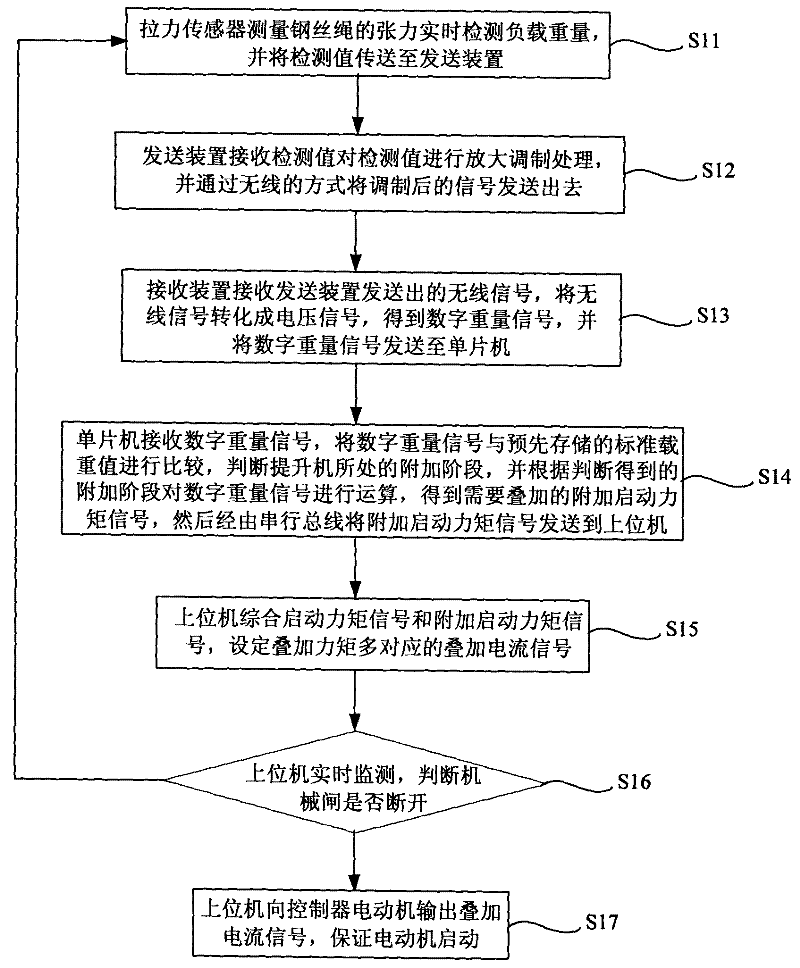

[0042] see figure 1 , a mine hoist additional starting torque given method for online load detection, comprising the following steps:

[0043] S11: The tension sensor measures the tension of the wire rope to detect the load weight in real time, and transmits the detected value to the sending device;

[0044] S12: The sending device receives the detected value, performs amplification and modulation processing on the detected value, and sends the modulated signal wirelessly;

[0045] S13: The receiving device receives the wireless signal sent by the sending device, converts the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com