Production method of sodium copper chlorophyllin

A copper chlorophyllin sodium salt and a production method technology are applied in the fine chemical industry to prepare natural pigments, which can solve the problems of large solvent consumption, multiple equipment, and lower yields, and reduce equipment investment, increase product yields, and save energy. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

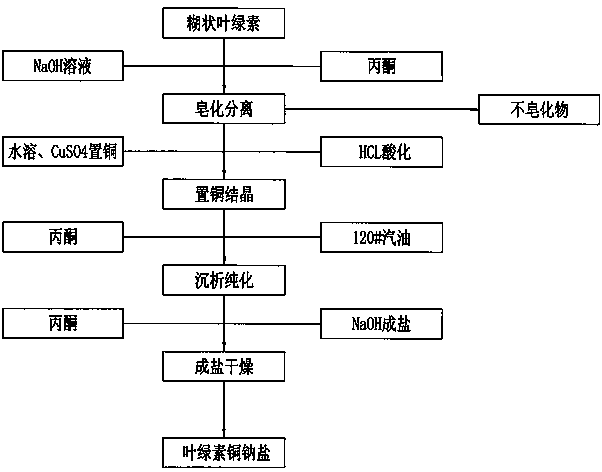

[0021] Such as figure 1 As shown, Example 1: A method for producing sodium copper chlorophyllin, using pasty chlorophyll as a raw material, including the following steps:

[0022] a. Saponification separation: directly add NaOH solution to the paste chlorophyll and stir to PH=12~14, control the temperature at 50℃, react for 60 minutes, control the stirring speed to 80 r / min, add paste to the reactant after the saponification reaction Dissolve 3 times the weight of chlorophyll in acetone, the temperature is controlled at 40℃, the stirring speed is controlled at 100 r / min to form a solid and liquid phase. The saponified solid is obtained by solid-liquid filtration, and then 1 to 2 times the acetone is added to repeatedly wash 2~4 times;

[0023] b. Copper crystals: Add 4 times the weight of pure water to the saponified solid obtained after saponification and separation to dissolve, and then add 3% CuSO by weight of paste chlorophyll 4 , Control the temperature to 50°C, and place the...

Embodiment 2

[0027] Example 2: A method for producing sodium copper chlorophyllin, using pasty chlorophyll as a raw material, including the following steps:

[0028] a. Saponification separation: directly add NaOH solution to the paste chlorophyll and stir to PH=12~14, control the temperature at 40℃, react for 90 minutes, control the stirring speed to 120 r / min, add the paste to the reactant after the saponification reaction Dissolve 5 times the weight of chlorophyll in acetone, the temperature is controlled at 45℃, and the stirring speed is controlled at 160 r / min to form a solid and liquid phase. The saponified solid is obtained through solid-liquid filtration, and then 1 to 2 times of acetone is added to repeatedly wash 2~4 times;

[0029] b. Set copper crystals: add 5 times the weight of pure water to dissolve the saponified solid obtained after saponification and separation, and then add 4% CuSO by weight of paste chlorophyll 4 , Control the temperature to 60°C, and set the copper for 30 m...

Embodiment 3

[0032] Example 3: A method for producing sodium copper chlorophyllin, using pasty chlorophyll as a raw material, including the following steps:

[0033] a. Saponification separation: directly add NaOH solution to the paste chlorophyll and stir to PH=12~14, control the temperature at 60℃, react for 70 minutes, control the stirring speed to 60 r / min, add paste to the reactant after the saponification reaction Dissolve 4 times the weight of chlorophyll in acetone, the temperature is controlled at 35℃, the stirring speed is controlled at 80 r / min to form a solid and liquid phase, the saponified solid is obtained by solid-liquid filtration, and then 1 to 2 times of acetone is added to repeatedly wash 2~4 times;

[0034] b. Copper crystals: Add 4 times the weight of pure water to the saponified solid obtained after saponification and separation to dissolve, and then add 3% CuSO by weight of paste chlorophyll 4 , Control the temperature to 55°C, set the copper for 30 minutes, after the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com