Device and method for measuring furnace top charge level of bell-less blast furnace

A blast-furnace, bell-less technology is applied in the field of blast-furnace ironmaking testing, which can solve the problems of high maintenance and use costs, many auxiliary equipment, influence on measurement accuracy, etc., and achieves the effects of strong real-time performance, high accuracy, and safe and reliable measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

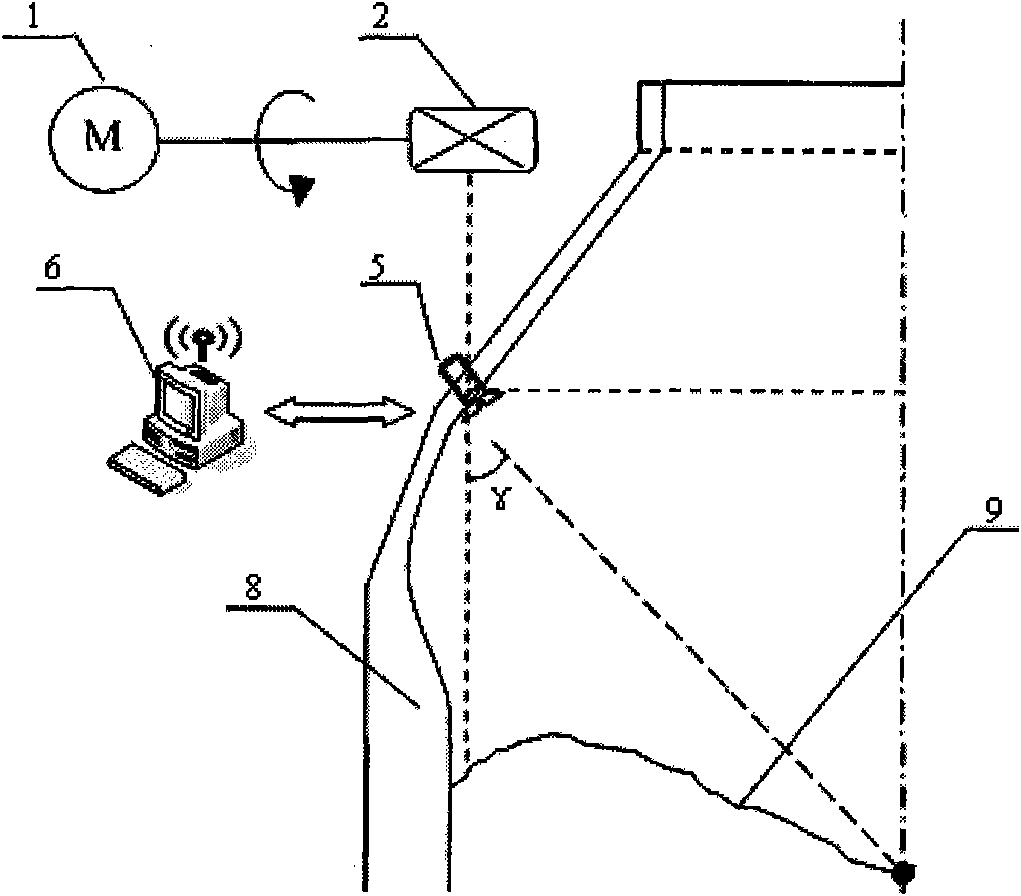

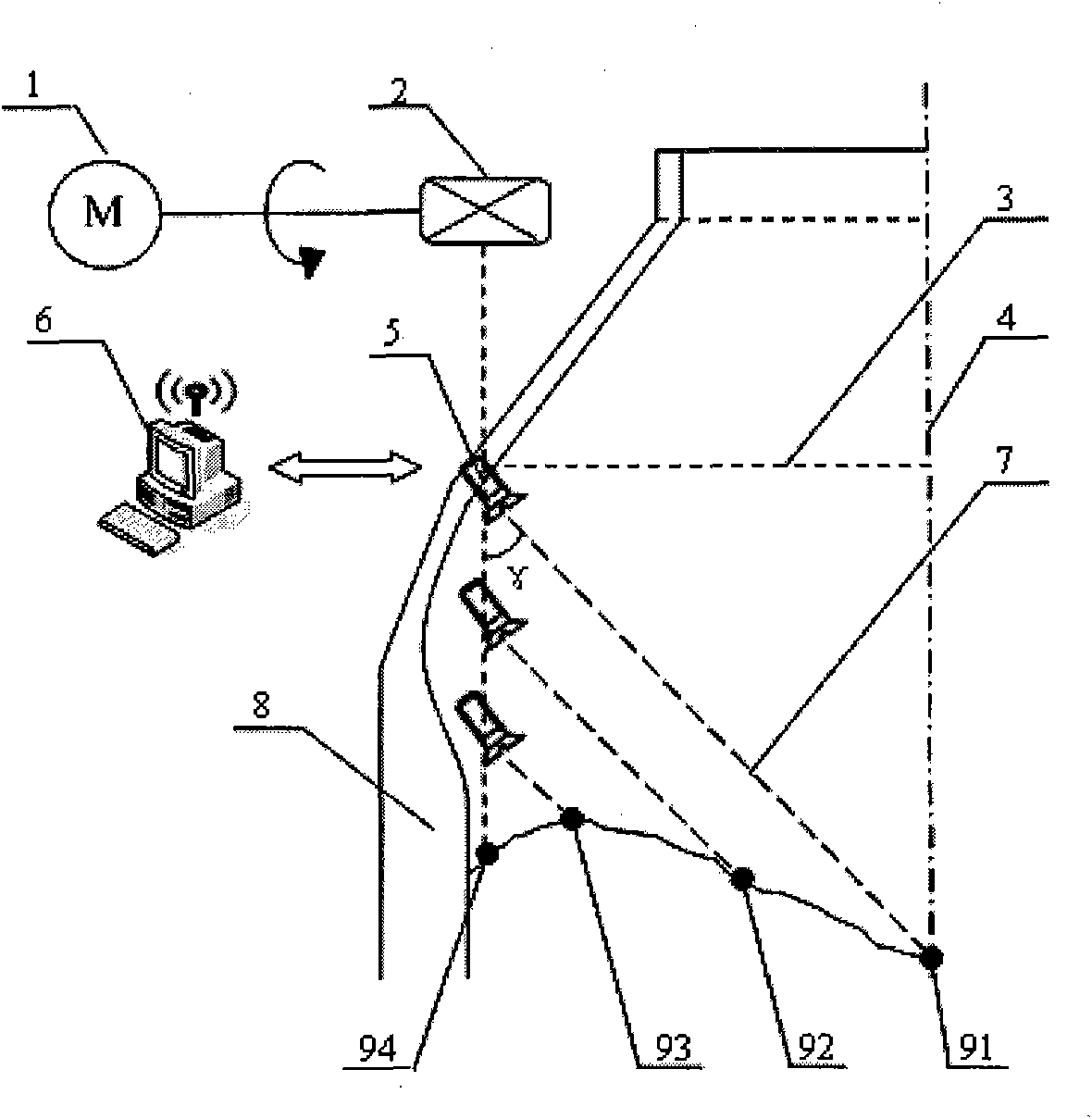

[0026] Below in conjunction with accompanying drawing, bellless blast furnace top charging surface measuring device and measuring method of the present invention are further described:

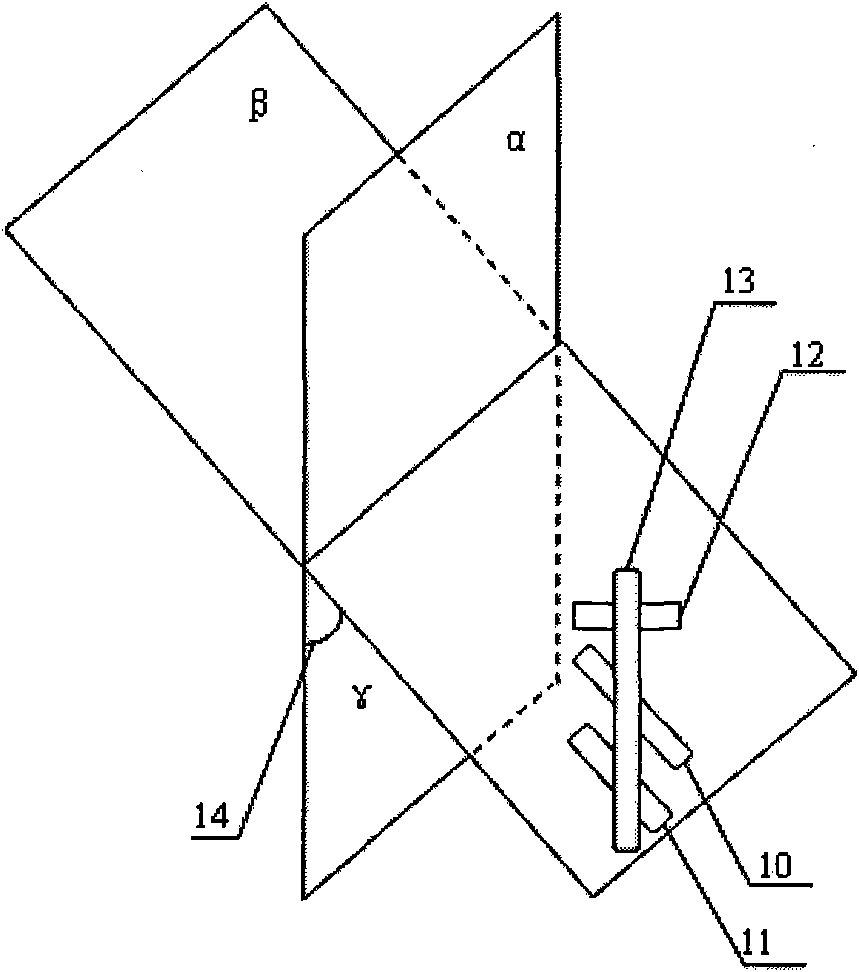

[0027] The bellless blast furnace roof material level measuring device of the present invention mainly includes a blast furnace probe device, a laser distance measuring device 5 and an external computer 6 . As shown in the accompanying drawings, the blast furnace probe device is mainly composed of a three-phase asynchronous motor 1, a probe transmission mechanism 2 and a probe 13. The probe transmission mechanism 2 is responsible for lowering or lifting the probe 13, and recording the distance between the probe 13 and zero. The distance of line zero position 3. The laser distance measuring device 5 is mainly composed of a laser distance measuring instrument 10 , a gyroscope 11 , a wireless communication instrument 12 and a probe 13 .

[0028] Before the measurement, the laser range finder 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com