Premelting type desulfurizing agent suitable for high-aluminum silicon steel and preparation method thereof

A desulfurizer and pre-melting technology, applied in the field of steelmaking vacuum refining, can solve the problems of decreased desulfurization performance, intensified erosion of magnesia-chromium refractory bricks, and excessive titanium content, and achieves the effects of high desulfurization rate, small erosion and easy preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

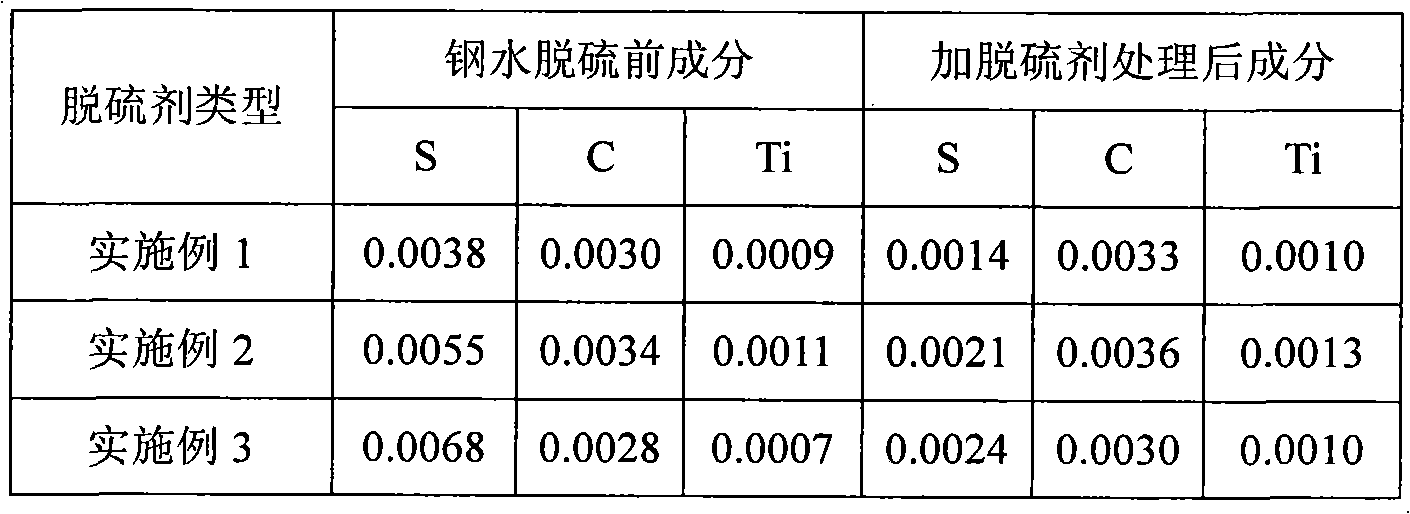

Examples

Embodiment Construction

[0013] The present invention will be further described below by way of examples.

[0014] The embodiment of the present invention carries out material selection, preparation and smelting according to the following methods:

[0015] (1) The raw material is high-quality limestone with a particle size of ≤10mm (including CaCO 3 more than 98%) and high-quality Al 2 o 3 (including Al 2 o 3 more than 98%).

[0016] (2) Add the raw materials into the mixer for mechanical mixing according to the following percentage by weight: limestone: 87% to 90%, Al 2 o 3 : 10% to 13%, the mixing time is 2 to 4 hours, ensure full mixing.

[0017] (3) Put the mixture into the smelting furnace and inject fuel oil for heating and smelting. The fuel oil used is low-sulfur heavy oil with a calorific value greater than 41840 kJ and a weight percentage of sulfur content less than 1.5%. The temperature of the furnace is raised to 1500-1600 ℃.

[0018] (4) Take it out of the oven, cool it down, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com