A method for purifying sewage in the production of sodium fluorosilicate

A sodium fluorosilicate and sewage purification technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increased viscosity of extraction slurry, fouling of filters and blockage of filter cloth , unfavorable rapid filtration of extraction slurry and other problems, to achieve the effect of reducing production cost, reducing usage, and good flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

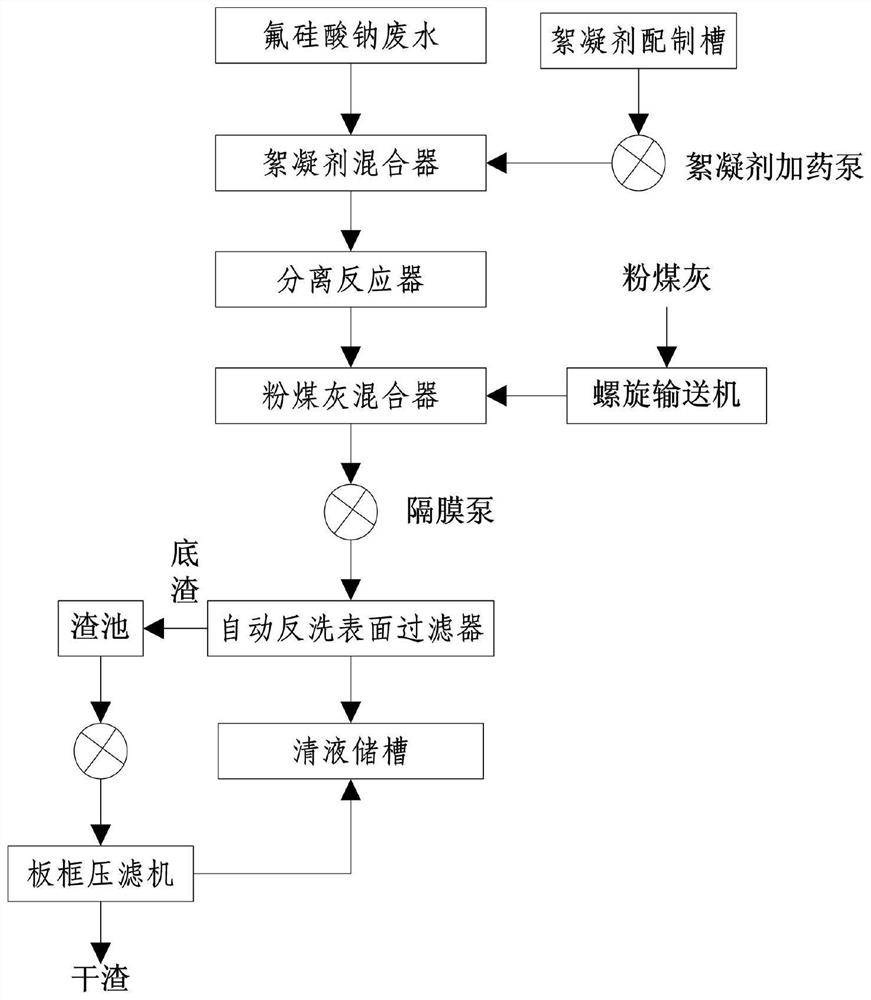

[0027] Such as figure 1 Shown, a kind of method for sewage purification in the production of sodium fluorosilicate comprises the following steps:

[0028] 1) Regulating Na in sewage + Content: In the preparation process of sodium fluorosilicate, the production process of sodium fluorosilicate was changed, the excessive precipitation method of sodium sulfate was changed to the excessive precipitation method of acid fluorosilicate, the conversion rate of sodium sulfate was improved, and the Na in the sewage of sodium fluorosilicate production was greatly reduced. + Content, Na in sewage + Content <500 mg / L, get sodium fluorosilicate production sewage;

[0029] 2) Flocculant settling: the sewage obtained in step 1) is mixed and reacted with the flocculant in the flocculant mixer, and the reaction liquid enters the separation reactor to remove a part of the suspended matter, and the filtrate 1 is obtained;

[0030] 3) Fly ash mixing: the filtrate 1 obtained in step 1) is mixed ...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of method for sewage purification in the production of sodium fluorosilicate comprises the following steps:

[0046] 1) Regulating Na in sewage + Content: In the preparation process of sodium fluorosilicate, the production process of sodium fluorosilicate was changed, the excessive precipitation method of sodium sulfate was changed to the excessive precipitation method of acid fluorosilicate, the conversion rate of sodium sulfate was improved, and the Na in the sewage of sodium fluorosilicate production was greatly reduced. + Content, Na in sewage + Content <500mg / L, get sodium fluorosilicate production sewage;

[0047] 2) Flocculant settling: the sewage obtained in step 1) is mixed and reacted with the flocculant in the flocculant mixer, and the reaction liquid enters the separation reactor to remove a part of the suspended matter, and the filtrate 1 is obtained;

[0048] 3) Fly ash mixing: the filtrate 1 obtained in step 1) is mixed w...

Embodiment 3

[0063] Such as figure 1 Shown, a kind of method for sewage purification in the production of sodium fluorosilicate comprises the following steps:

[0064] 1) Regulating Na in sewage + Content: In the preparation process of sodium fluorosilicate, the production process of sodium fluorosilicate was changed, the excessive precipitation method of sodium sulfate was changed to the excessive precipitation method of acid fluorosilicate, the conversion rate of sodium sulfate was improved, and the Na in the sewage of sodium fluorosilicate production was greatly reduced. + Content, Na in sewage + Content <500mg / L, get sodium fluorosilicate production sewage;

[0065] 2) Flocculant settling: the sewage obtained in step 1) is mixed and reacted with the flocculant in the flocculant mixer, and the reaction liquid enters the separation reactor to remove a part of the suspended matter, and the filtrate 1 is obtained;

[0066] 3) Fly ash mixing: the filtrate 1 obtained in step 1) is mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com