Terylene jacquard blackout face fabric

A fabric, polyester technology, applied in the field of polyester jacquard shading fabrics, to achieve the effect of clear pattern, good shading and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

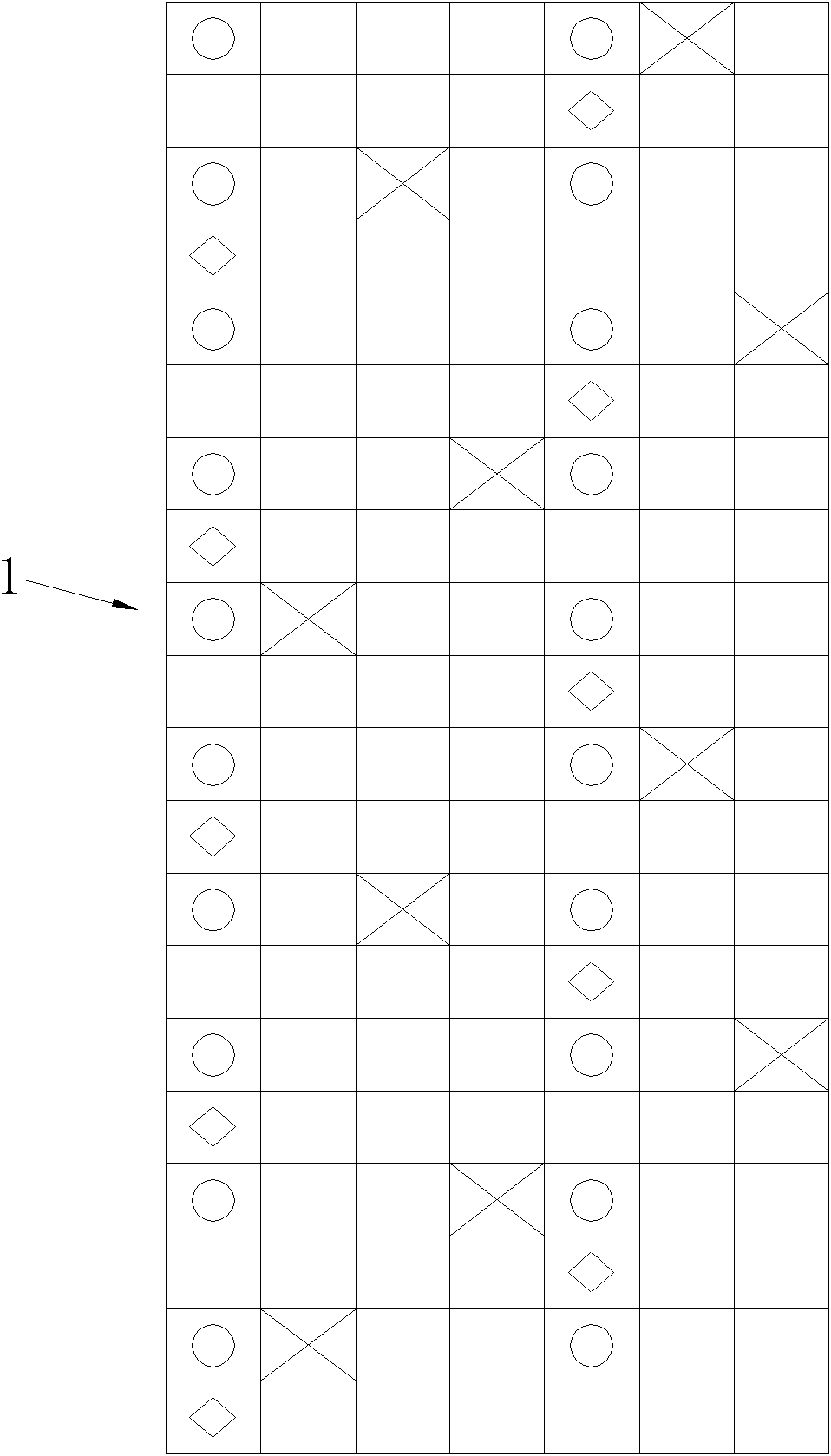

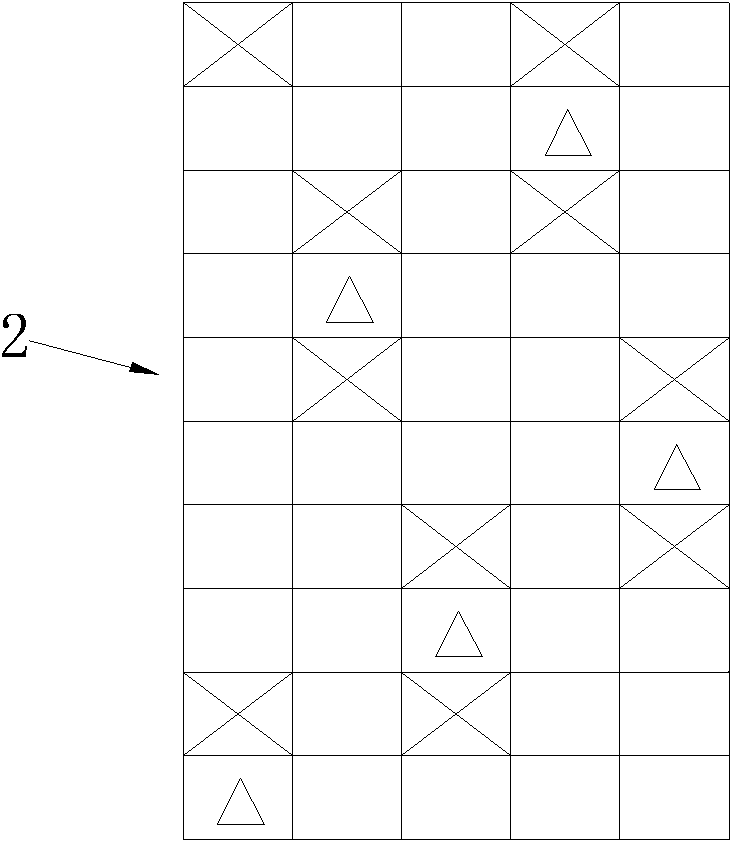

Image

Examples

Embodiment 1

[0015] Example 1: A polyester jacquard shading fabric, woven with 1 set of warp yarns and 3 sets of weft yarns, 1 set of warp yarns using 75D / 36F semi-dull polyester filaments, and the first weft in the 3 sets of weft yarns using 150D / 96F polyester black silk , B weft is 150D / 48F polyester low elastic yarn, C weft is 300D / 96F cationic polyester low elastic yarn; the warp density is 150 teeth; the weft density is 90 teeth; the total number of warp yarns is 47040; The arrangement ratio with the weft yarn in the ground tissue 1 is 1:1.

Embodiment 2

[0016] Embodiment 2: A polyester jacquard shading fabric, which is woven with 1 set of warp yarns and 3 sets of weft yarns, 1 set of warp yarns is made of 120D / 65F semi-dull polyester filaments, and the first weft of the 3 sets of weft yarns is made of 300D / 160F polyester black silk , B weft is 200D / 78F polyester low elastic yarn, C weft is 400D / 576F cationic polyester low elastic yarn; the warp density is 160 teeth; the weft density is 85 teeth; the total number of warp yarns is 55000; The arrangement ratio with the weft yarn in the ground tissue 1 is 2:1.

Embodiment 3

[0017] Example 3: A polyester jacquard shading fabric, which is woven with 1 set of warp yarns and 3 sets of weft yarns, 1 set of warp yarns is made of 100D / 78F semi-dull polyester filaments, and the first weft of the 3 sets of weft yarns is made of 260D / 180F polyester black silk , the second weft is 320D / 144F polyester low elastic yarn, the third weft is 350D / 288F cationic polyester low elastic yarn; the warp density is 130 teeth; the weft density is 120 teeth; the total number of warp yarns is 62030; the flower structure is 2 The arrangement ratio of the weft yarns in the ground structure 1 is 2:3.

[0018] The fabric adopts three processes of warp drawing, heald drawing, and machine weaving. Among them, the upper machine weaving adopts a wide-width double-warp double-axis electronic jacquard water-jet loom. The upper machine weaving is the key to determine the quality of the fabric. If there is any problem in weaving, It will be directly reflected on the cloth surface, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com