High-density yarn dye jacquard shading fabric

A high-density color and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of affecting normal weft insertion, general shading effect, and different number of warp yarns, so as to reduce pollution, compact structure, and pattern rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

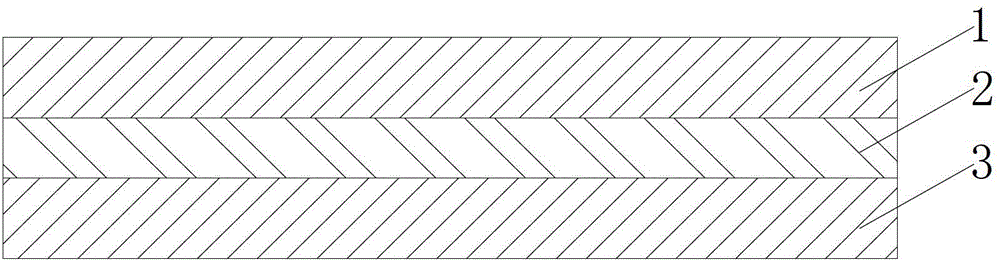

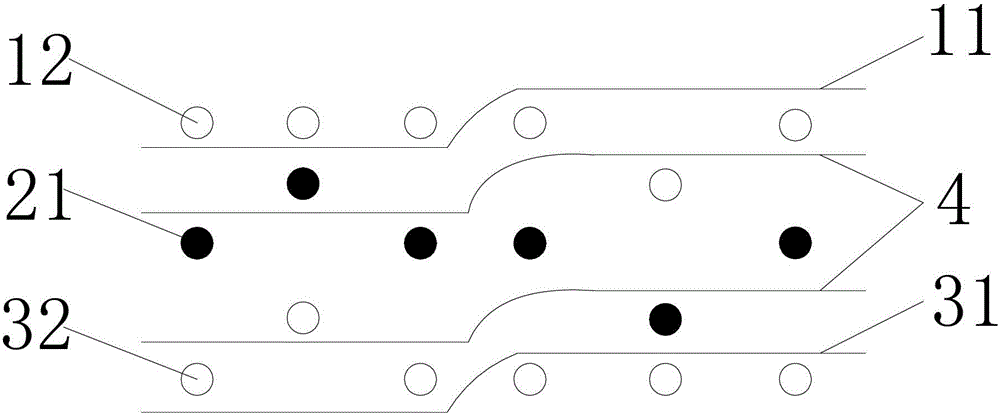

[0014] A high-density yarn-dyed jacquard shading fabric of the present invention comprises an upper structure 1, a middle structure 2 and a lower structure 3, the yarns used in the upper structure 1 and the lower structure 3 are stock solution dyed fibers, and the middle structure 2 is made of black silk 21. The weft yarn of the raw material is formed. The superstructure 1 is formed by interweaving surface warp 11 (warp yarn in the superstructure) and surface weft 12 (weft yarn in the superstructure). The lower structure 3 is formed by interweaving the inner warp 31 (the warp yarn in the lower structure) and the inner weft 32 (the weft yarn in the lower structure), and the inner warp and the inner weft are interwoven to form the inner structure. The upper structure 1 and the lower structure 3 There are a number of floating long lines inside, and the floating long lines cover the surface tissue and the inner tissue. The upper structure 1 is connected to the middle structure 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com