Start-stop control method for double air compressor of locomotive

An air compressor, start-stop control technology, applied in the direction of pump control, machine/engine, mechanical equipment, etc., can solve the problems of poor water separation effect and high failure rate, and achieve the effect of reducing the number of start-stop times and prolonging the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

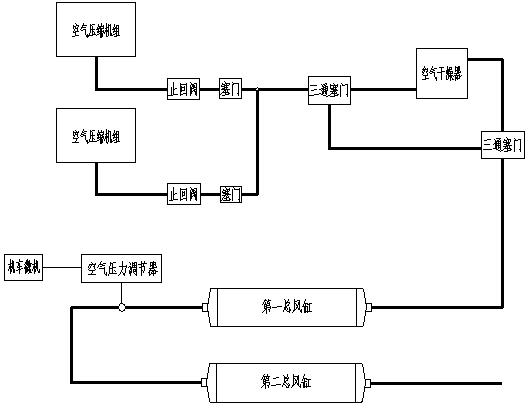

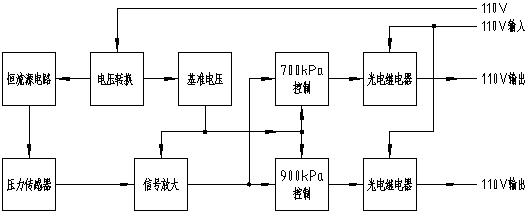

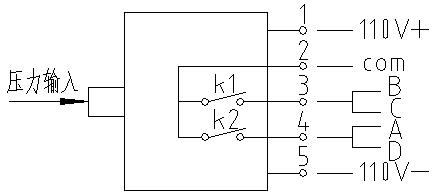

[0014] A method for controlling the start and stop of dual air compressors on a locomotive, comprising connecting an air pressure regulator to the first main air cylinder, the air pressure regulator is connected to the locomotive microcomputer, and the air pressure regulator and the control system in the locomotive microcomputer are jointly To control the start and stop of the air compressor, the information transmission process of the air pressure regulator is as follows: use the pressure sensor inside the air pressure regulator to take pressure sampling → convert the circuit → switch the pressure of the first main air cylinder through its internal photoelectric relay The signal is transmitted to the locomotive microcomputer, and the air pressure regulator pre-sets four pressure levels of A, B, C, and D for the first master air cylinder, and the control system in the locomotive microcomputer automatically implements the control strategy according to the pressure value of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com