Suction surface sucking stator blade of air compressor

A technology of stator blades and suction surfaces, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high power suction equipment and high cost of funds, etc., achieve effective suction and save test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

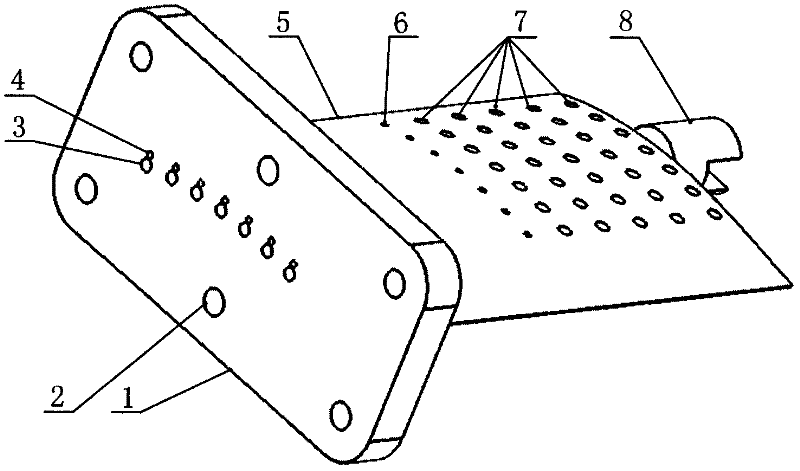

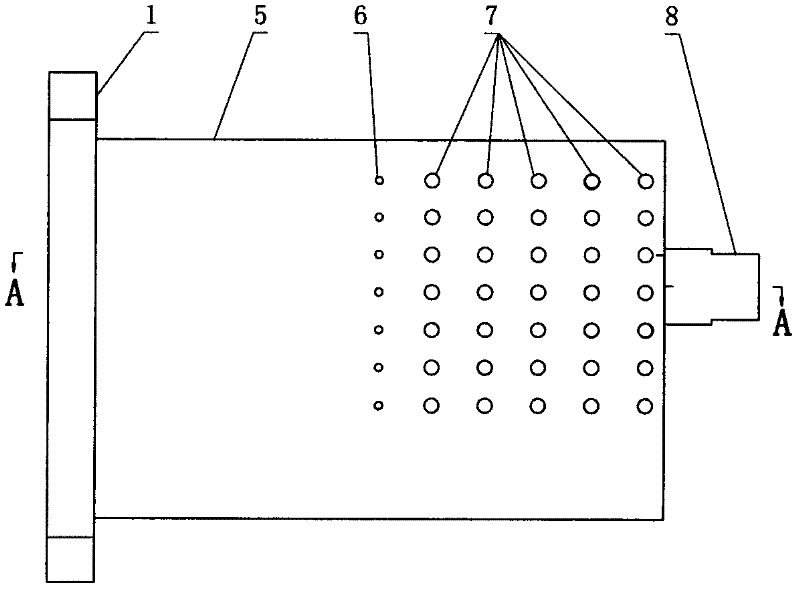

[0024] This embodiment is a compressor stator blade with suction surface suction, which is used for boundary layer suction and testing on the 0-50% span area of the suction surface of the compressor stator blade.

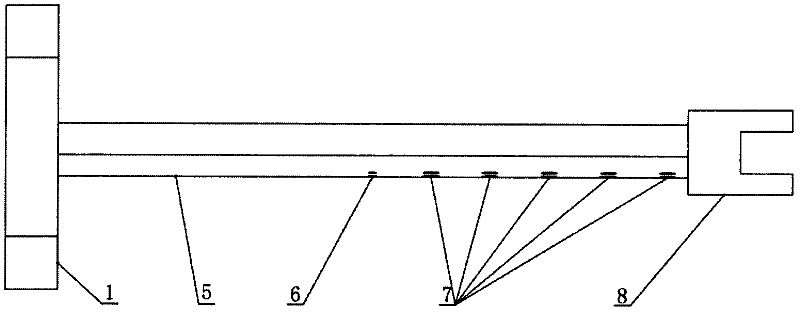

[0025] Such as figure 1 As shown, a stator blade of a suction side suction compressor proposed in this embodiment includes a blade body 5 and a blade shroud 1 . There is a fixed pin 8 at the blade tip. There are 35 suction holes 7 and 7 static pressure holes 6 distributed on the suction surface of the blade body 5 .

[0026] The suction holes 7 are divided into 7 rows, uniformly arranged from the leading edge to the trailing edge of the blade body 5, and the distance between the center of the first row of suction holes 7 and the leading edge of the blade is 12% of the chord length, the seventh The distance between the center of the row of suction holes 7 and the trailing edge of the blade is 28% of the chord length; the distance between the first row of suction ...

Embodiment 2

[0035] This embodiment is a compressor stator blade with suction surface suction, which is used to perform boundary layer suction and test on the 45-100% blade span area of the suction surface of the compressor stator blade.

[0036] Such as figure 1 As shown, a stator blade of a suction side suction compressor proposed in this embodiment includes a blade body 5 and a blade shroud 1 . There is a fixed pin 8 at the blade tip. There are 25 suction holes 7 and 5 static pressure holes 6 distributed on the suction surface of the blade body 5 .

[0037] The suction holes 7 are divided into 5 rows, which are uniformly arranged from the leading edge to the trailing edge of the blade body 5, and the distance between the center of the first row of suction holes 7 and the leading edge of the blade is 50% of the chord length, the fifth The distance between the center of the row of suction holes 7 and the trailing edge of the blade is 10% of the chord length; the distance between the f...

Embodiment 3

[0046] This embodiment is a compressor stator blade with suction surface suction, which is used to perform boundary layer suction and test on the 20-80% span area of the suction surface of the compressor stator blade.

[0047] Such as figure 1 As shown, a stator blade of a suction side suction compressor proposed in this embodiment includes a blade body 5 and a blade shroud 1 . There is a fixed pin 8 at the blade tip. There are 90 suction holes 7 and 9 static pressure holes 6 distributed on the suction surface of the blade body 5 .

[0048] The suction holes 7 are divided into 9 rows, 10 in each row, evenly arranged from the leading edge to the trailing edge of the blade body 5, and the distance between the center of the first row of suction holes 7 and the leading edge of the blade is 10%. Chord length, the distance between the center of the ninth row of suction holes 7 and the trailing edge of the blade is 15% of the chord length; the distance between the first row of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com