Device and method for measuring heat storage coefficient of material by harmonic method based on independent sensor

A heat storage coefficient, independent technology, applied in the direction of material thermal conductivity, etc., can solve the problems of difficulty in insulation, repeated preparation of flat metal sensors, inability to accurately characterize liquid and powder samples, etc., to achieve the effect of cost reduction and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Various details involved in the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

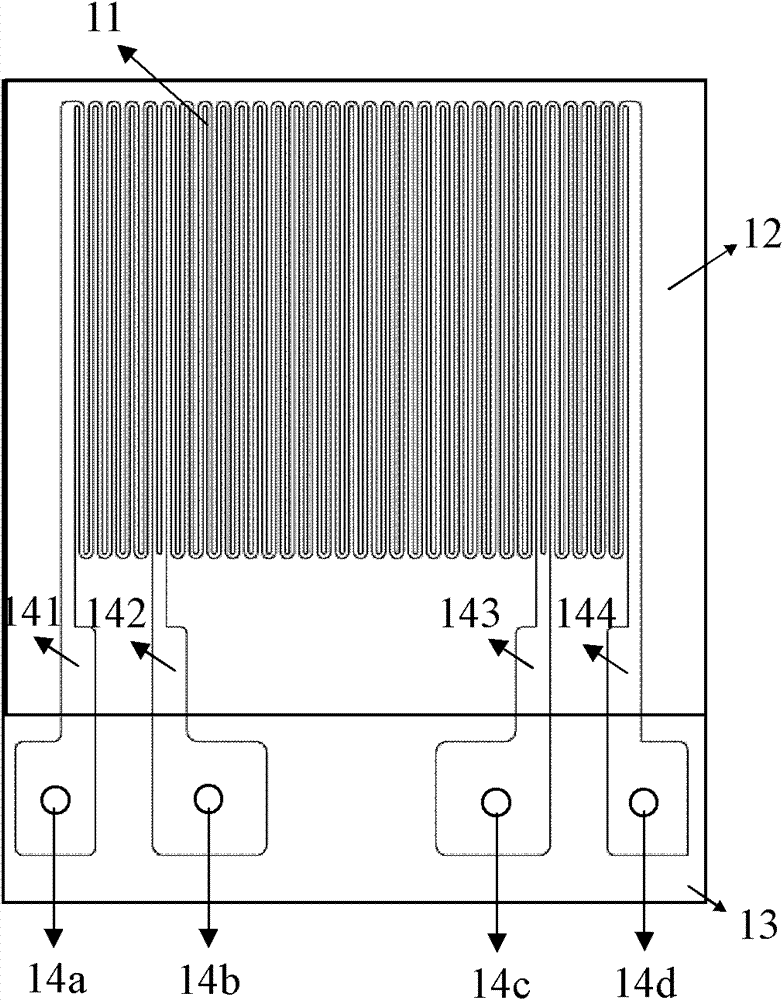

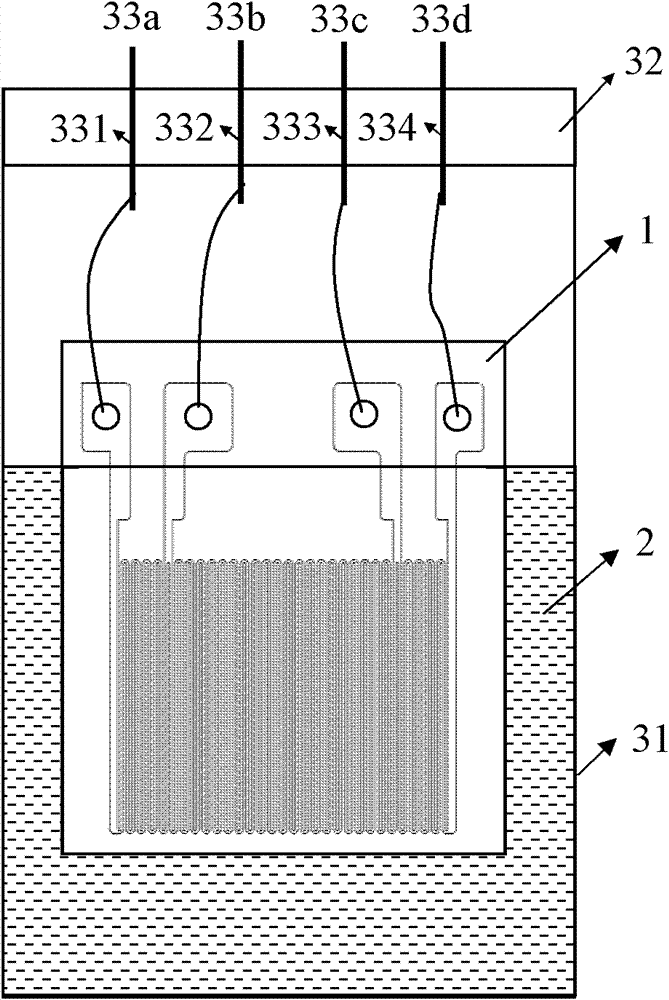

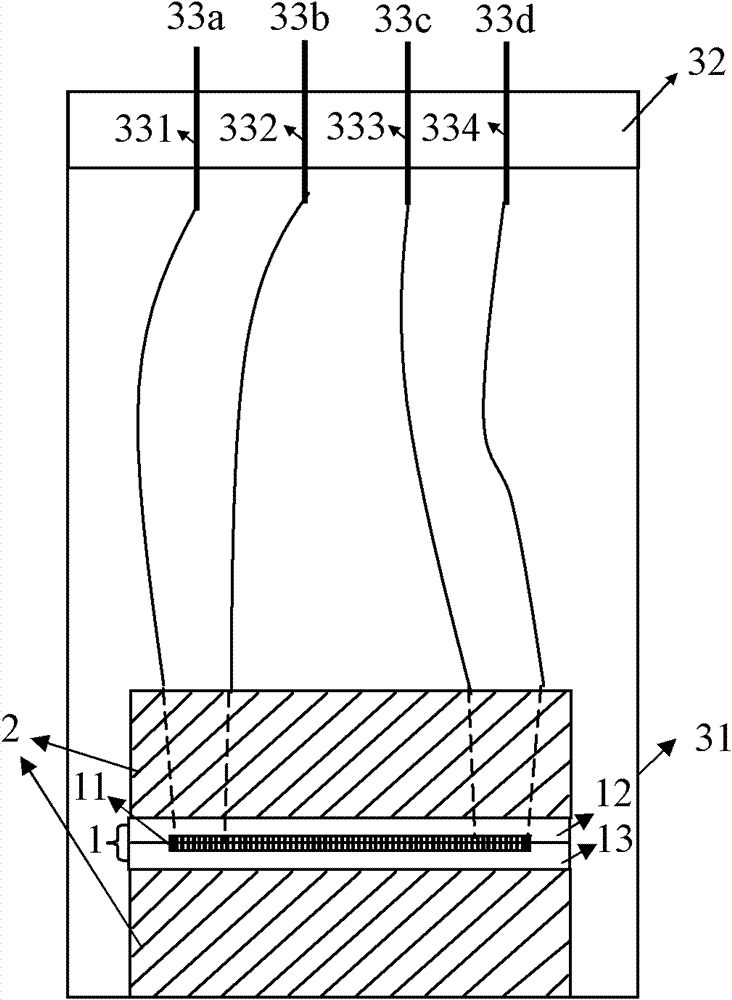

[0047] A device and method for measuring heat storage coefficient of materials based on an independent sensor based on harmonic method of the present invention involves using an independent sensor sandwiched between two identical solid samples instead of directly depositing the sensor on the surface of the sample, using a The structure of the independent sensor vertically placed in the liquid / powder sample replaces the technical solution of depositing the sensor on the surface of another standard solid sample, and realizes the non-destructive test of the thermal storage coefficient of the sample to be tested. Before testing, use standard ethylene gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com