Ultrasonic phased array micro-cavitation micro-fluidic detection system

An ultrasonic phased array and detection system technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., can solve problems such as omission of crack detection and incomplete workpiece detection. , to improve the detection accuracy, facilitate remote control, improve the degree of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

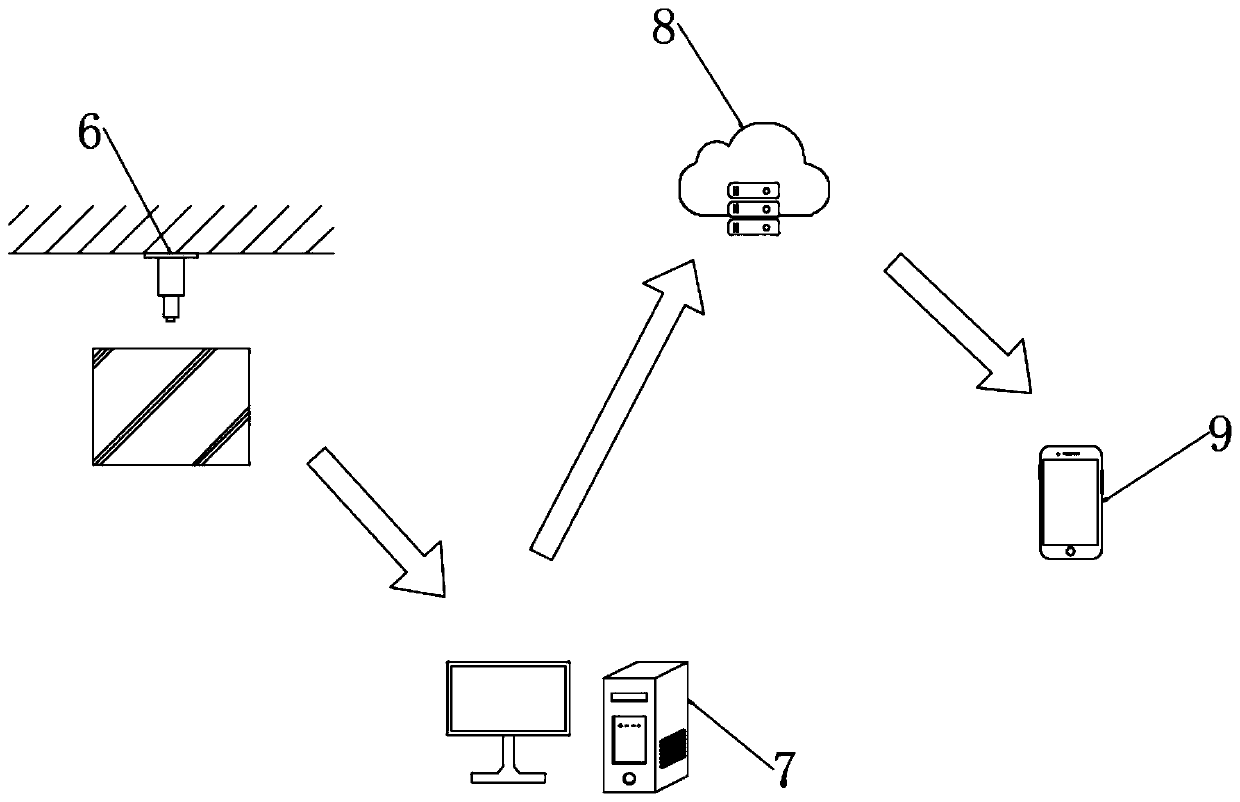

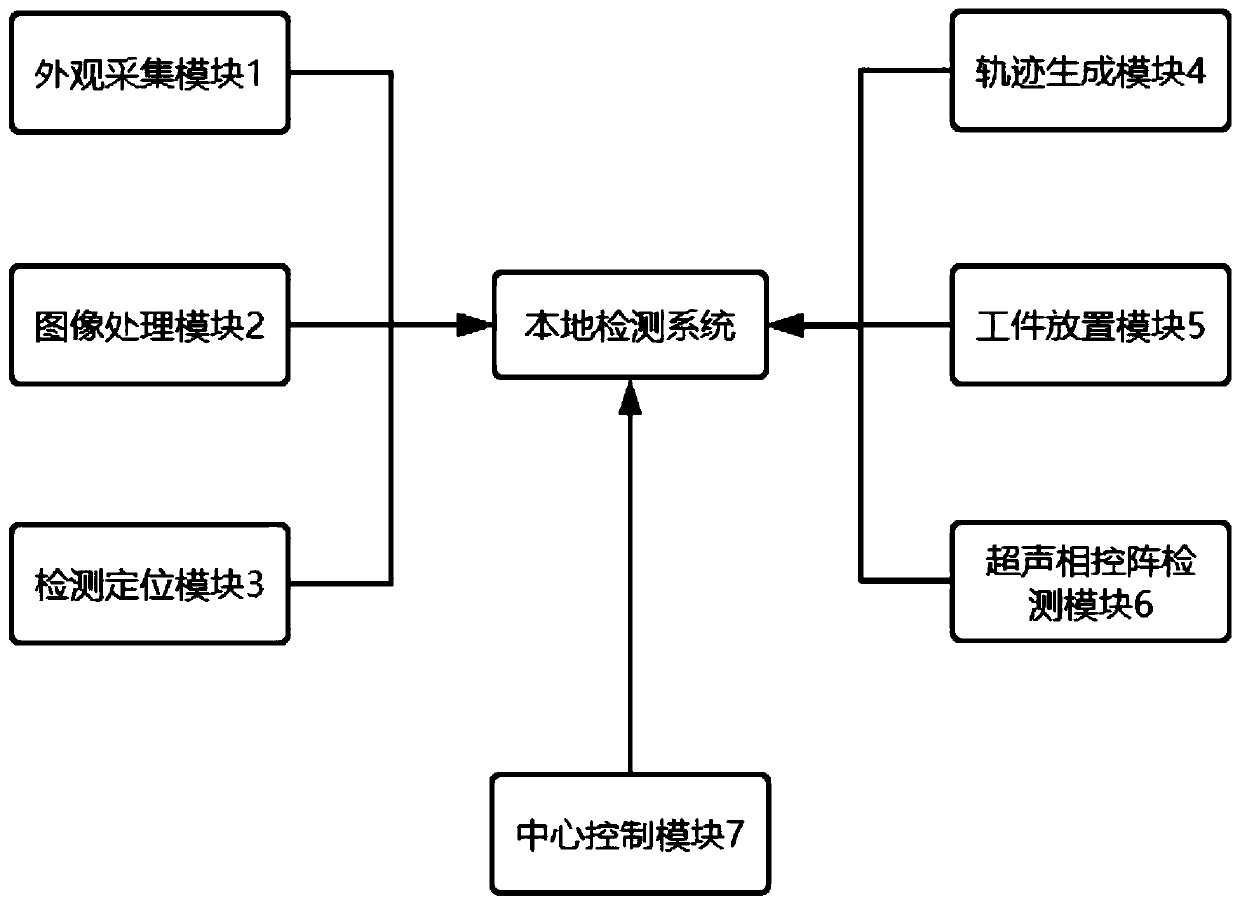

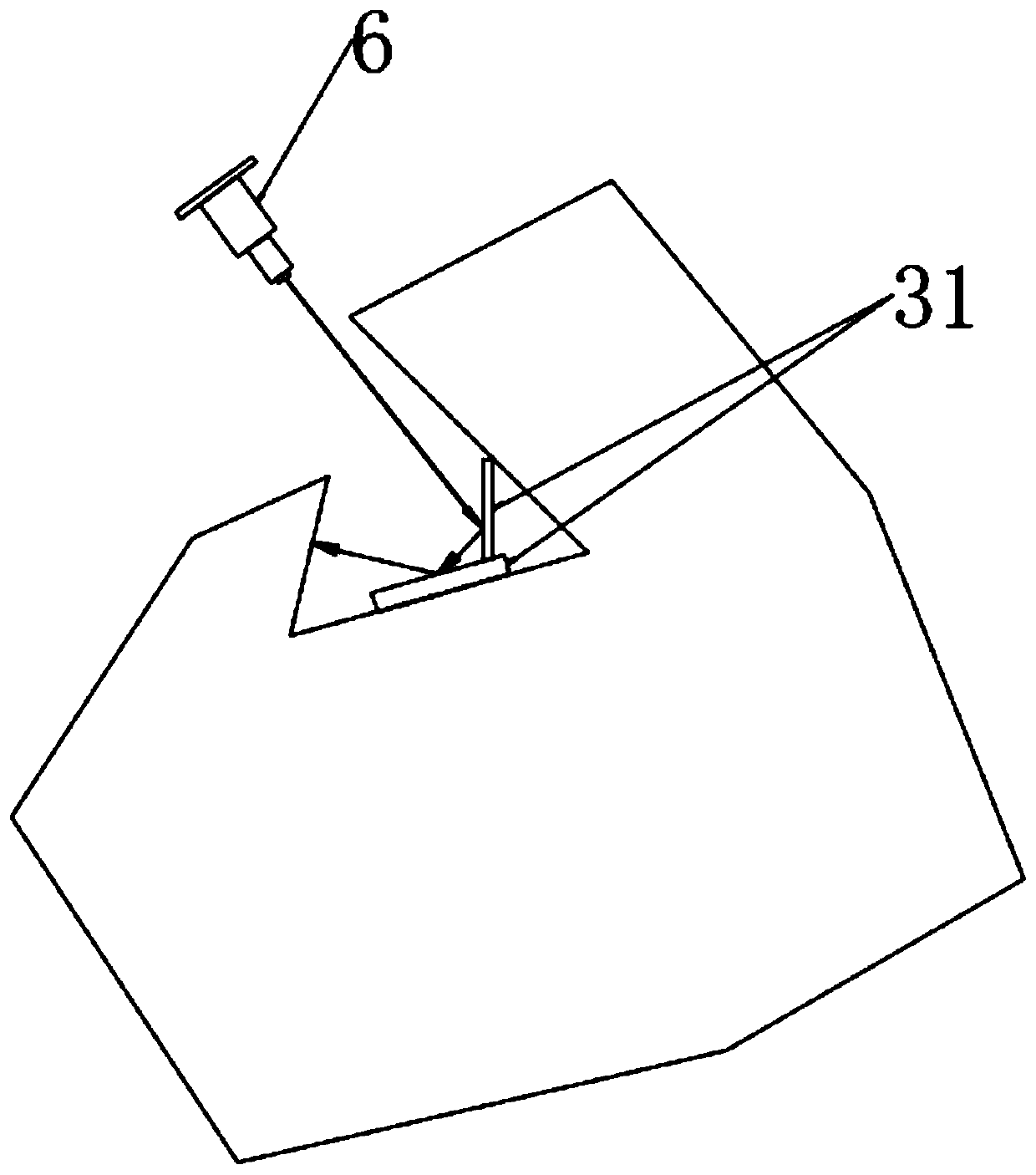

[0036] see Figure 1-3, Ultrasonic phased array microcavitation microfluidic detection system, including a local detection system, the local detection system includes appearance acquisition module 1, image processing module 2, detection and positioning module 3, trajectory generation module 4, workpiece placement module 5, ultrasonic phase The array detection module 6 and the central control module 7, the appearance acquisition module 1 includes no less than 6 high-definition cameras, and at least six directions corresponding to the workpiece should be observed to ensure the complete acquisition of the appearance of the workpiece. The image processing module 2 includes The image enhancement unit, filter processing unit, gray scale conversion unit, feature extraction unit and image segmentation unit can easily obtain the best detection track and the best detection angle after image processing, and find hidden points that cannot be directly detected in advance. The workpiece pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com