Foil-type coiling machine with cold pressure welding device

A welding device and winding machine technology, applied in welding equipment, coil manufacturing, non-electric welding equipment, etc., to achieve the effects of coil tightness, damage prevention, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

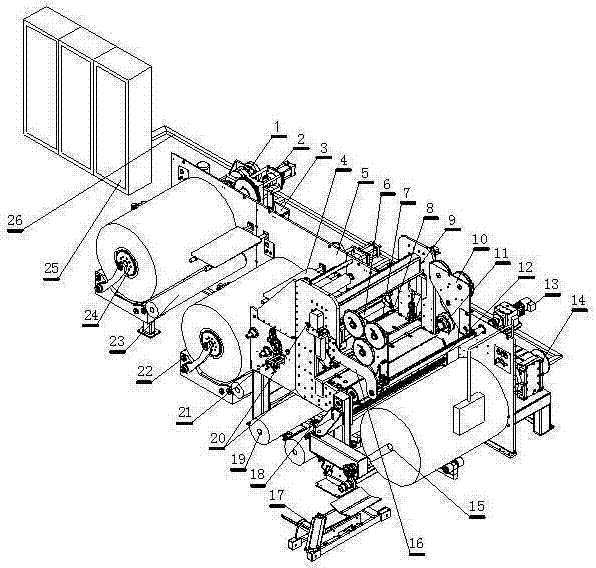

[0019] A foil winding machine with cold press welding device, such as figure 1 As shown, it consists of foil feeding device 1, foil uncoiling device 2, deflection adjustment device 3, support frame 4, main frame 5, pre-welding cleaning device 6, electric grinder 7, angle bracket 8, cold press welding device 9. Edge belt uncoiling device 10, layer insulation transmission device 11, insulation shearing device 12, edge belt transmission device 13, winding device 14, winding spindle 15, flat strip bracket 16, winding machine sliding bracket 17 , insulating sliding bracket 18, layer insulating uncoiling device 19, screw bearing 20, trimming device 21, end support device 22, release piece rewinder device 23, unwinding spindle 24, control device 25 and control device cable 26 , the specific connection relationship is as follows: the main frame 5 is provided with an end sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com