Rubbish bag-breaking machine

A bag breaking machine and garbage technology, applied in the direction of grain processing, etc., can solve the problems of insufficient cutting of garbage bags, troublesome staff health, poor bag breaking effect, etc., and achieve the effect of simultaneous cutting, good effect and sufficient cutting work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

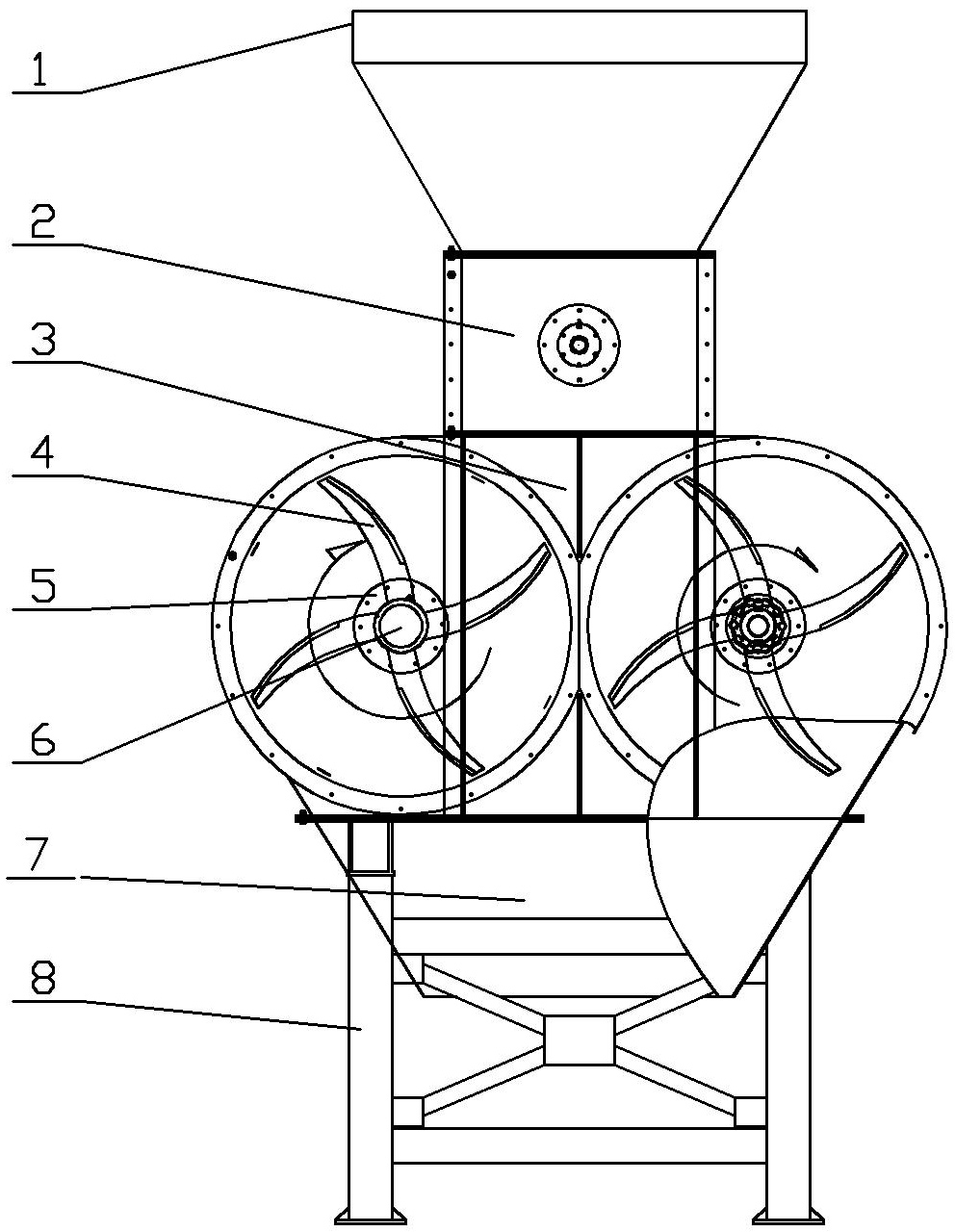

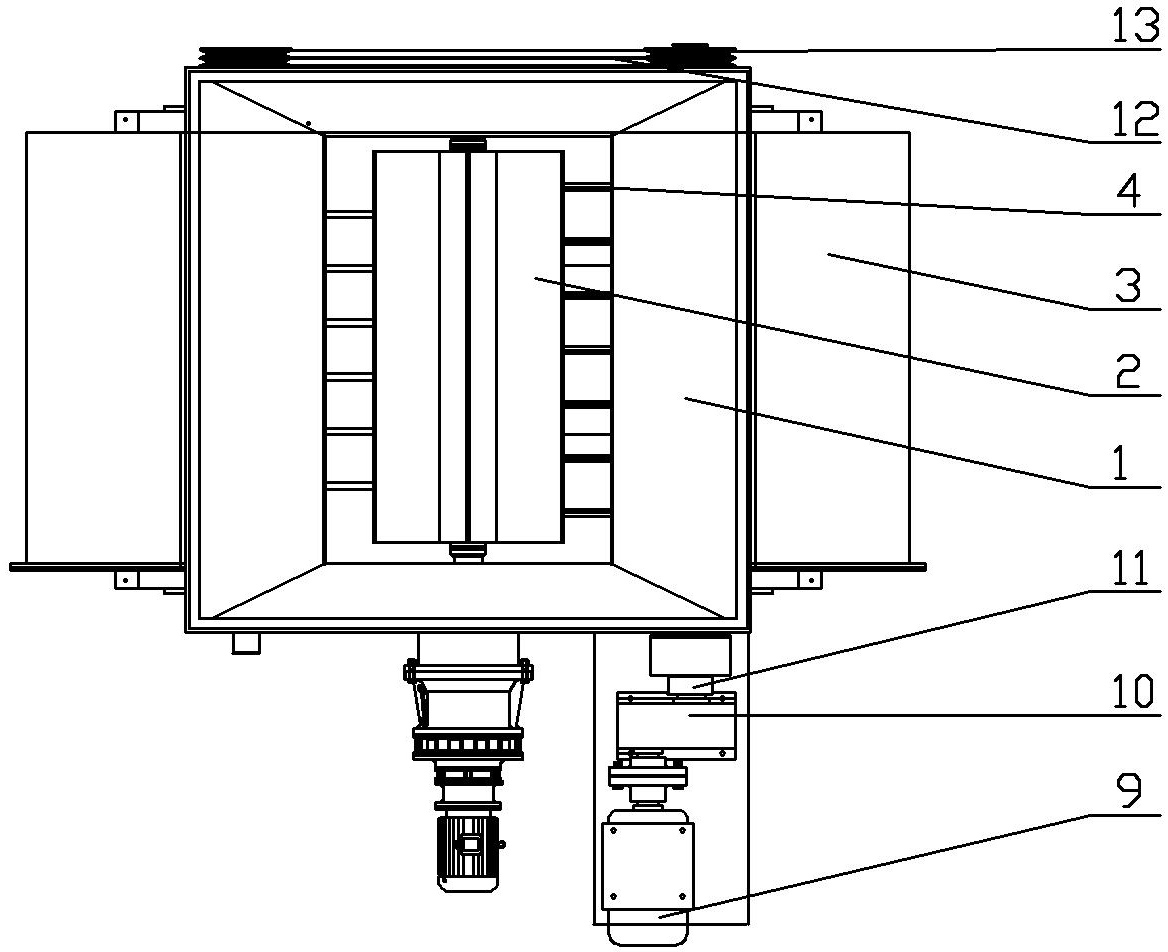

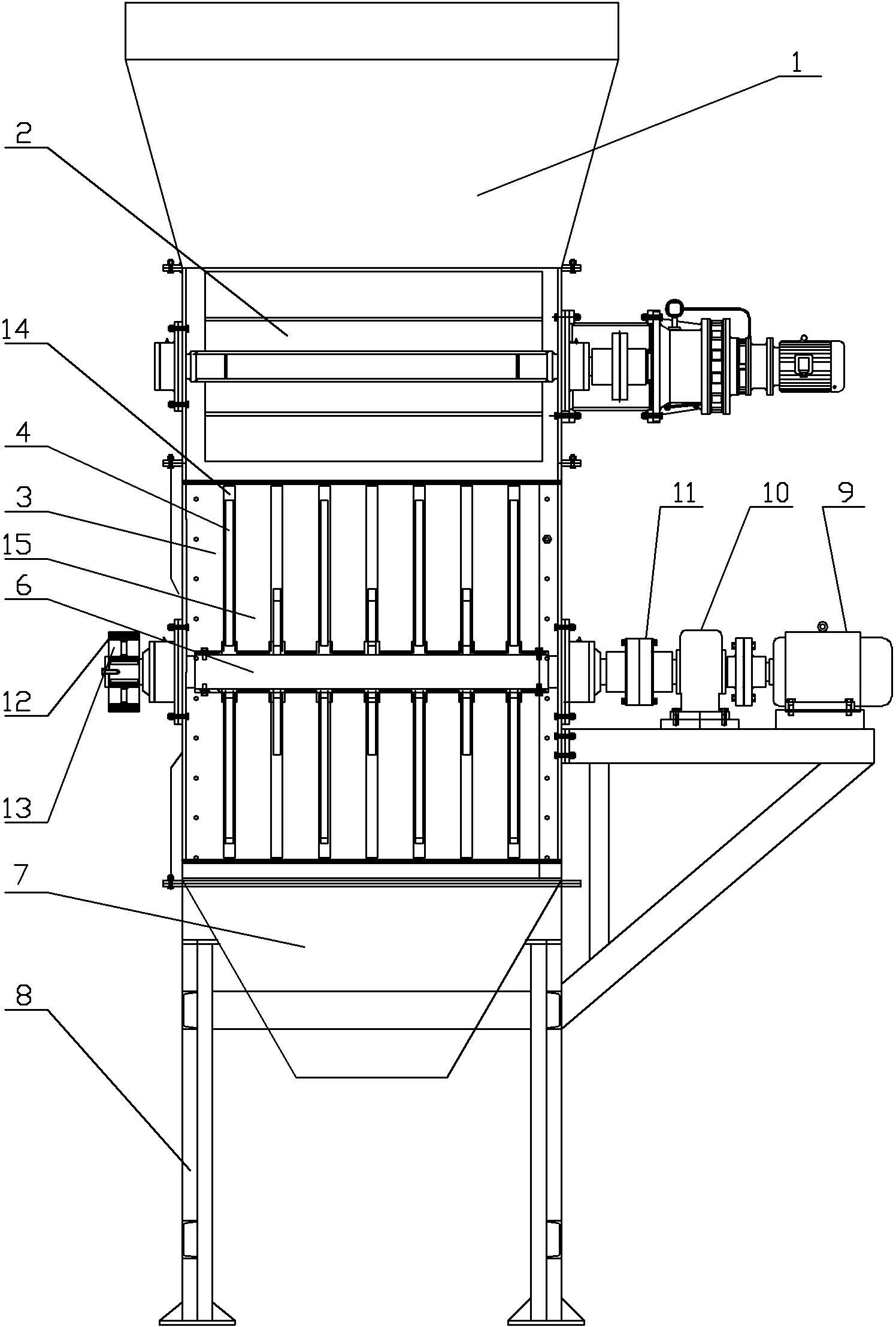

[0019] As shown in the figure, the present invention includes a bag breaking box 3, an upper feeding funnel 1 is arranged at the upper end of the middle part of the bag breaking box 3, a lower discharge funnel 7 is arranged at the lower end of the middle part of the bag breaking box 3, and left and right symmetrically arranged in the bag breaking box 3 Two sets of impellers 5, the blades 4 of the impellers 5 are knife-shaped with cutting edges, the main shafts 6 of the two impellers are connected by a pulley 13 and a belt 12, and the main shaft 6 of one group of impellers is connected to the motor 9 through a coupling 11, a reducer 10 connected. The bottom of the broken bag box 3 can be supported with a certain height by the steel structure support foot 8, which is beneficial to the output of the discharge. The wall of the broken bag box 3 below the two impellers 5 can be set to the inclined slant plate to the middle part, which is convenient for the whereabouts of the debri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com