Device and method for producing amorphous and nano-crystalline alloy strip

An amorphous nanocrystalline and alloy strip technology is applied in the field of preparation of amorphous soft magnetic alloy strips, and achieves the effects of stable strip quality, production cost savings, and stable stripping pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

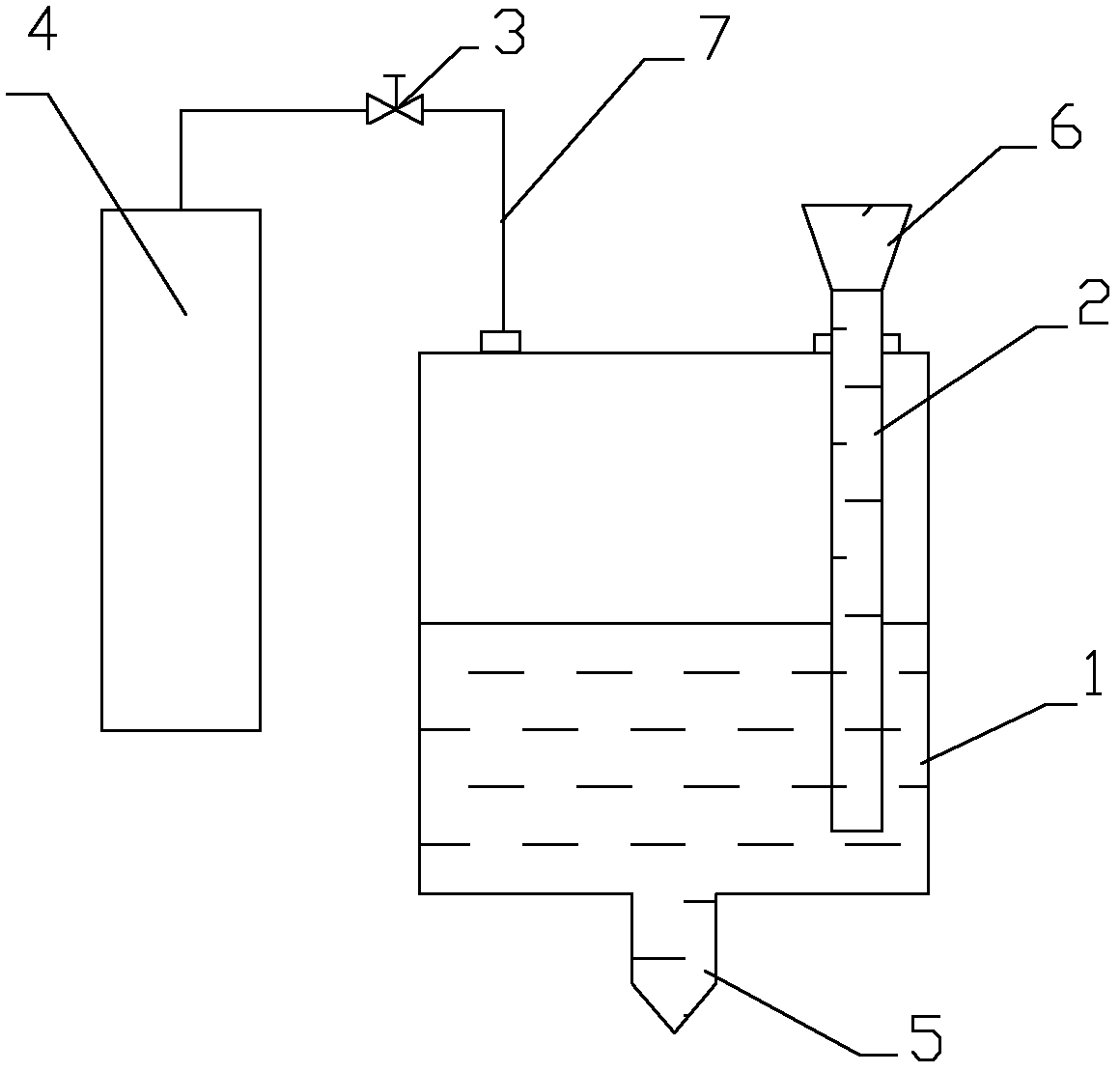

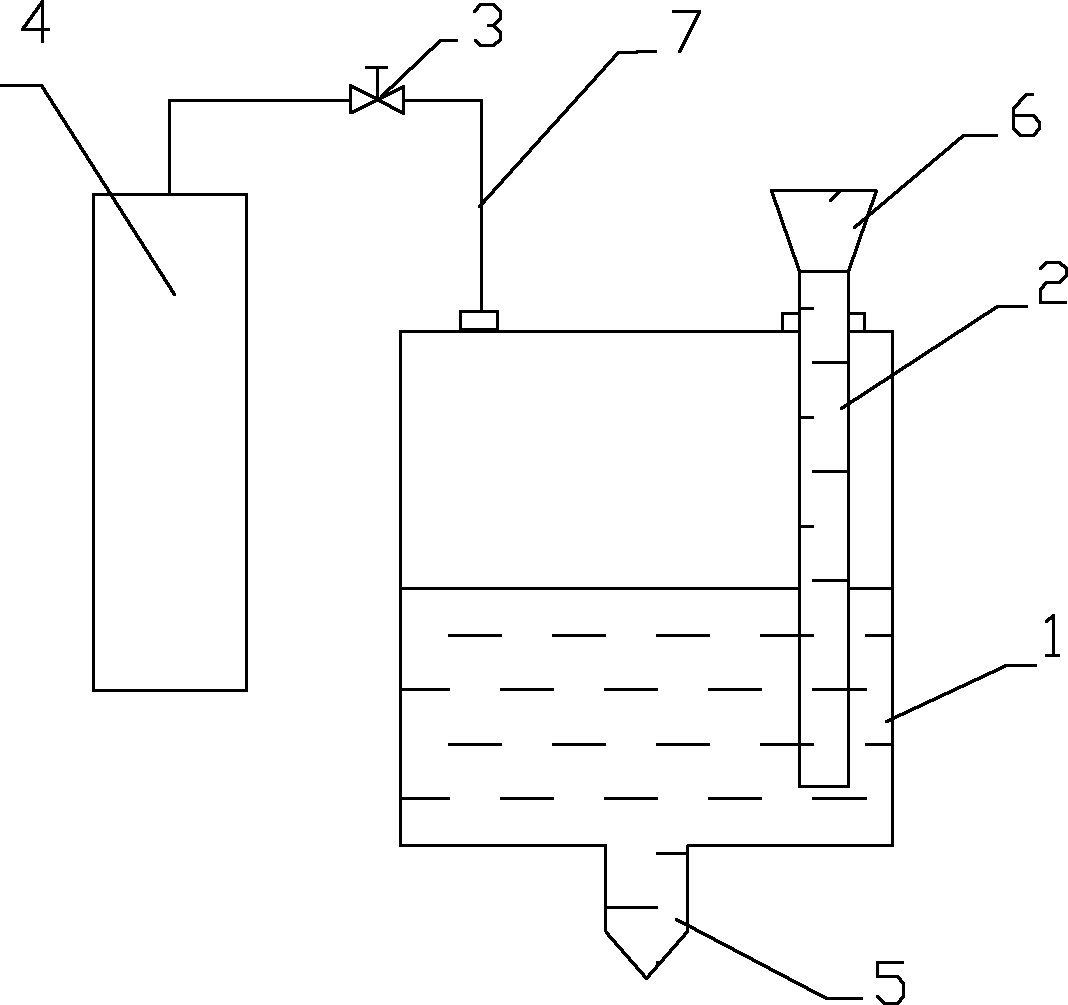

[0016] The present invention will be further described by embodiment now in conjunction with accompanying drawing.

[0017] The strip spraying device of the present invention is as shown in the figure, the crucible 1 upper connection port as spraying device is connected with a draft tube 2 whose lower end extends to the bottom of the crucible 1, and the crucible 1 passes through the gas delivery pipe from its upper connection port 7 and the regulating valve 3 arranged on the gas delivery pipe 7 are connected to the inert gas storage tank 4, and the nozzle 5 is connected to the lower connection port of the crucible 1;

[0018] The preparation method of the strip of the present invention is to input the pressure gas into the sprayer while inputting the molten steel into the sprayer, and adjust the input spraying method manually or automatically according to the change of the molten steel level in the sprayer. The pressure of the gas of the injector is used to maintain the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com