Mobile transfer trolley

A trolley and frame technology, which is applied in the field of mobile transfer trolleys, can solve the problems of reducing the reliability of the transfer trolley, inconvenient operation of the front baffle, time-consuming and laborious operation, etc., so as to reduce auxiliary operation time, facilitate manual operation, and improve transportation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

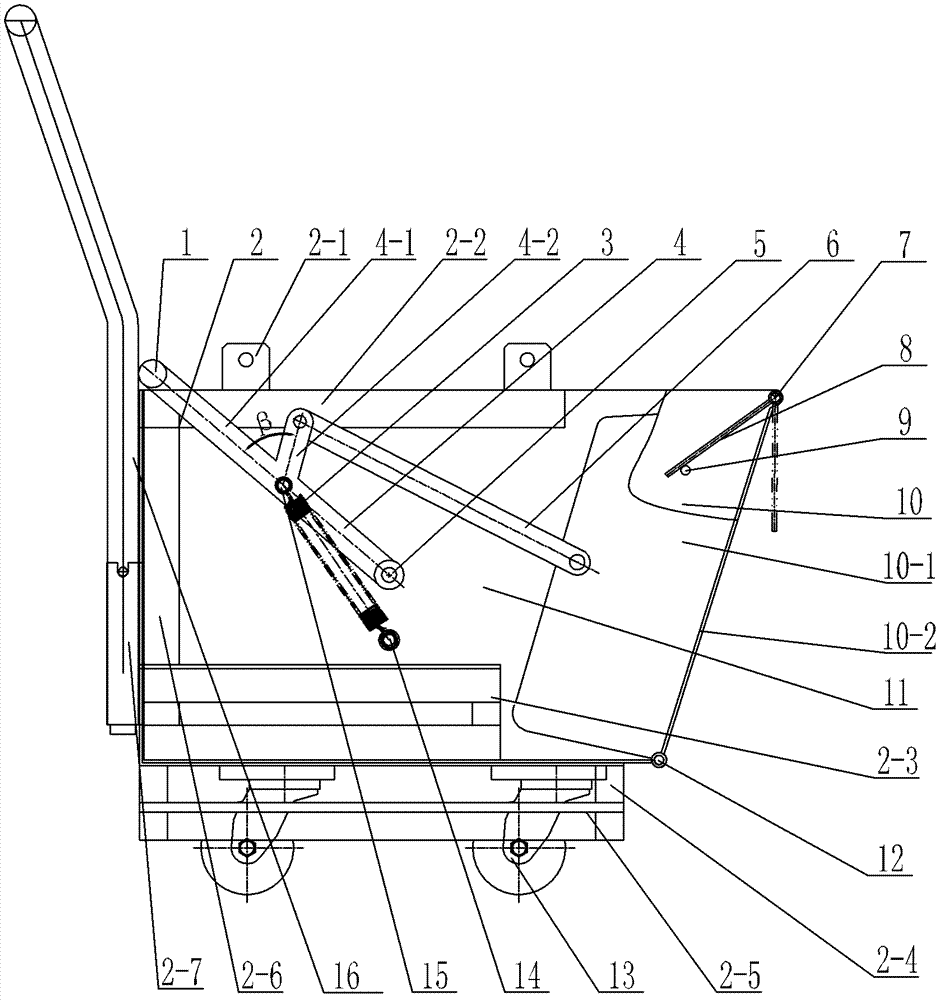

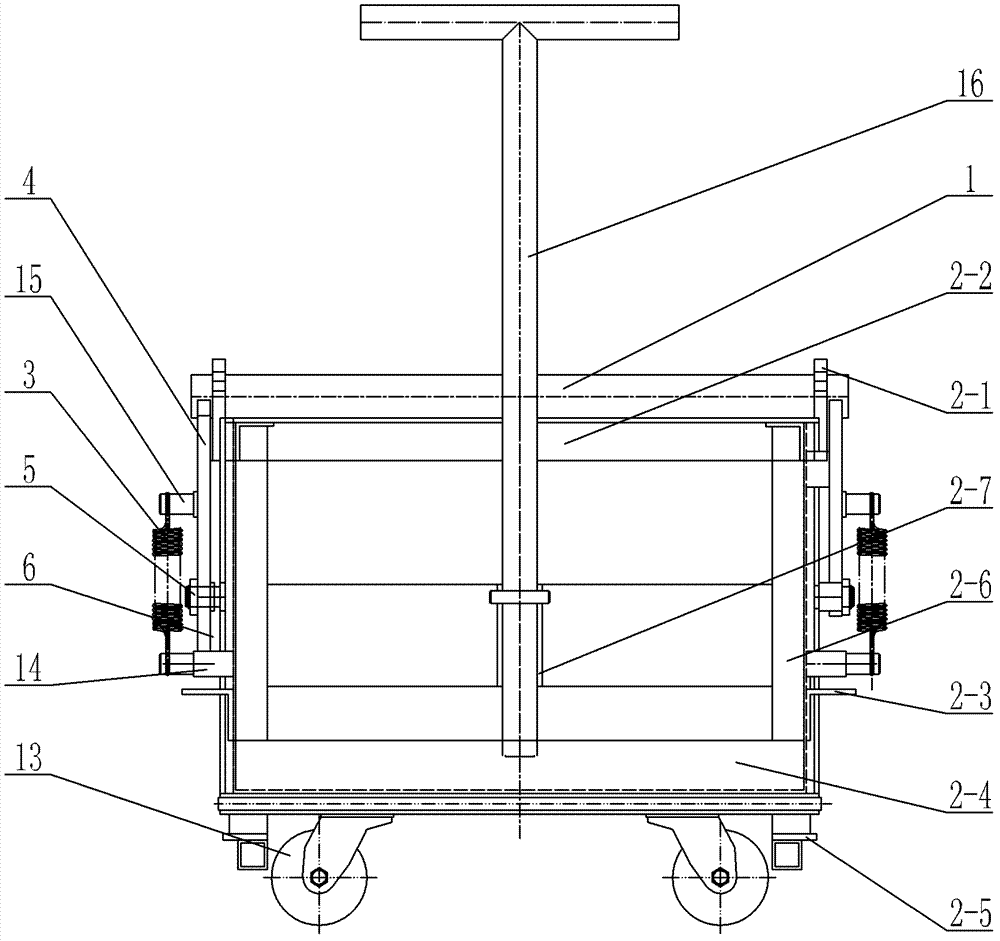

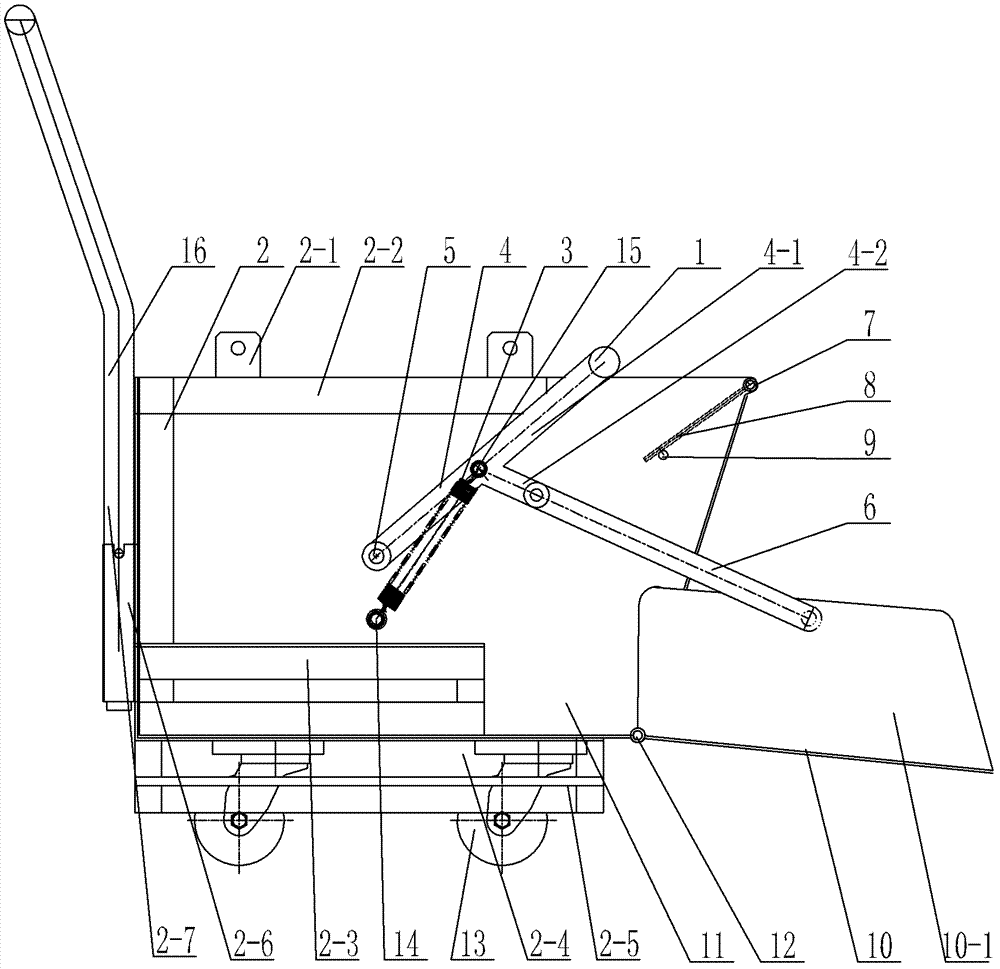

[0011] See Figure 1~3 As shown, the mobile transfer trolley of the present invention includes a vehicle frame 2 and at least three universal wheels 13 installed at the bottom of the vehicle frame 2. The universal wheels 13 adopt existing wheels, and the universal wheels 13 can be arranged in a triangular shape or at four corners. Set, the vehicle frame 2 comprises more than four columns 2-6 and the upper beam 2-2 and the bottom beam 2-4 fixed on the upper and lower sides of each column 2-6, and the column 2-6 can adopt angle iron or channel steel , and the upper beam 2-2 and the bottom beam 2-4 can adopt angle iron and be welded on the upper and lower sides of each column 2-6 respectively, the front part of the upper beam 2-2 is open, so that the vehicle frame 2 becomes a front end with an opening. Frame structure, the two sides of the vehicle frame 2 of the present invention also have side beams respectively, and the side beams on the vehicle frame 2 are erected and respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com