Steel plate spring support

A technology of leaf springs and support plates, applied in the direction of springs, springs/shock absorbers, leaf springs, etc., can solve the problems that the leaf springs cannot function effectively and are deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

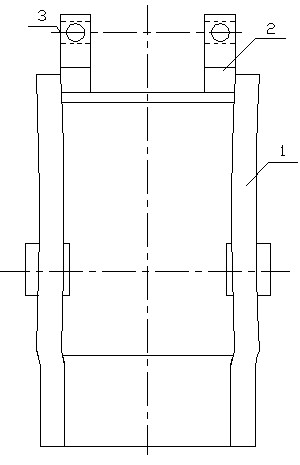

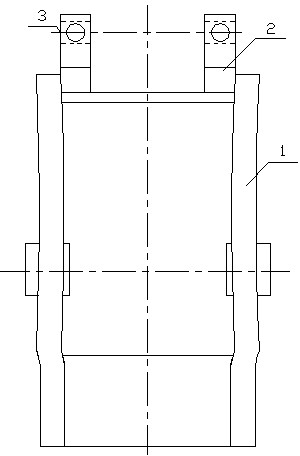

[0011] The specific implementation of the leaf spring bracket of the present invention will be described below with reference to the accompanying drawings.

[0012] see figure 1 As shown, the leaf spring support of the present invention includes two support plates 1 symmetrically arranged, and the two support plates 1 are respectively fixed with lifting lug bearings 2, and the two lifting lug bearings 2 are provided with coaxial lifting lugs. A trunnion hole 3, wherein the two support plates 1 have a protruding arc relative to each other.

[0013] Through the above-mentioned technical scheme of the present invention, after the whole vehicle is installed, since the support plate 1 of the leaf spring support of the present invention is pre-formed with relative to each other protruding radian, so the deformation that occurs under the weight of the whole vehicle, the support plate will be slightly The curved plate with a radian becomes a flat plate, so that the deformation due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com