Convex wafer workpiece grinding device

A technology for grinding devices and wafers, which is applied in the direction of grinding workpiece supports, machine tools suitable for grinding workpiece planes, grinding machines, etc., which can solve problems such as high requirements for workers' operating skills, uneven force application, and short service life of thimbles. Low operating skill requirements, reduced spherical eccentricity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

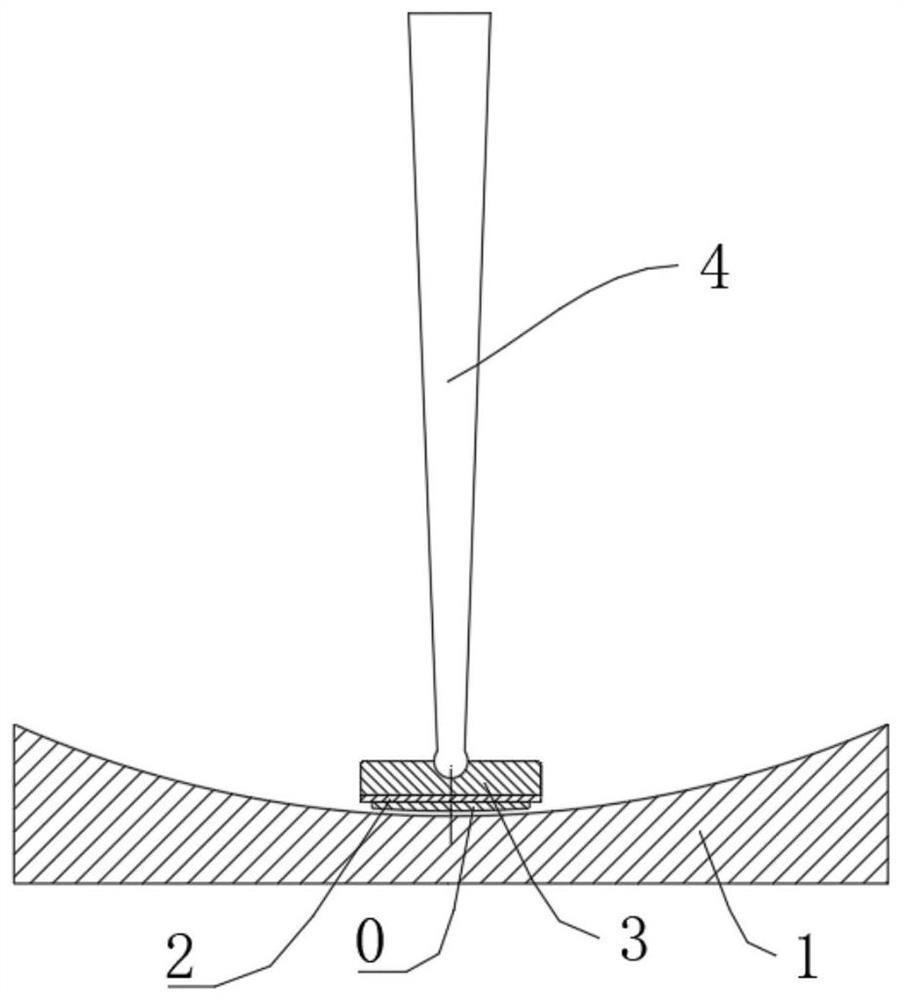

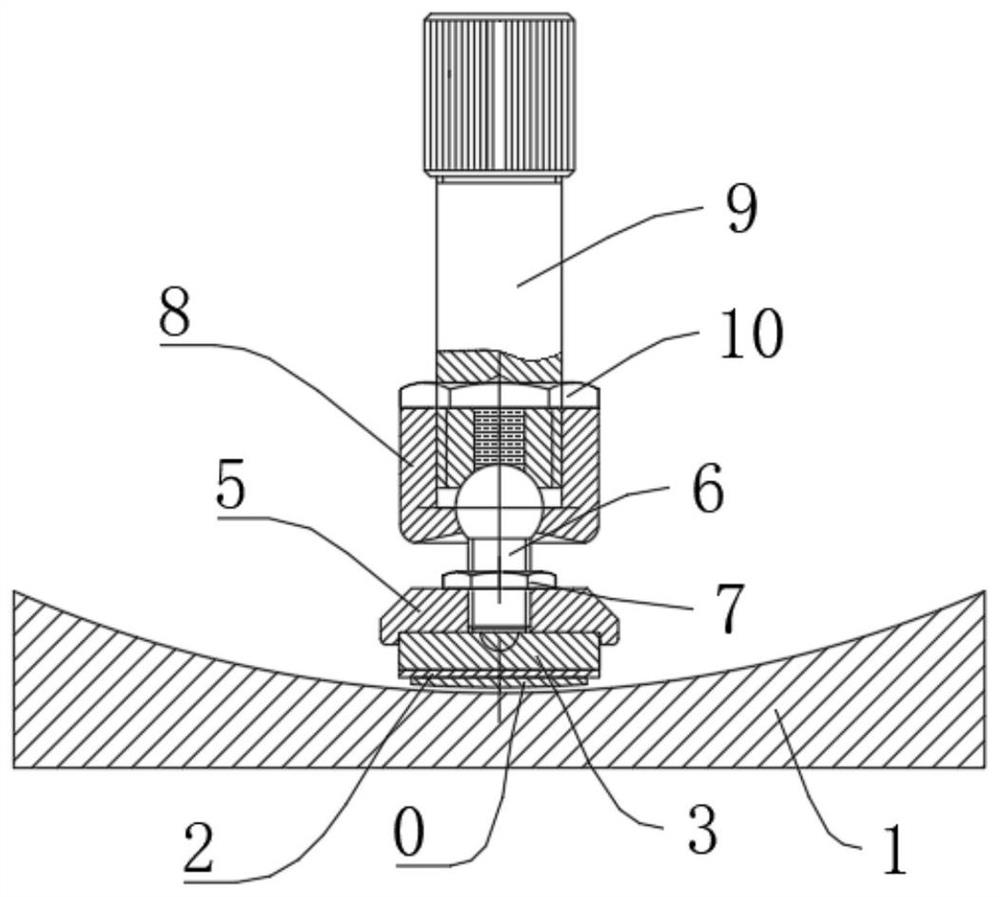

[0121] Such as Figure 2 to Figure 6 as shown,

[0122] This embodiment provides a convex wafer workpiece grinding device,

[0123] Including concave spherical grinding disc 1 and suction disc 3;

[0124] The suction disc 3 is located above the concave spherical grinding disc 1;

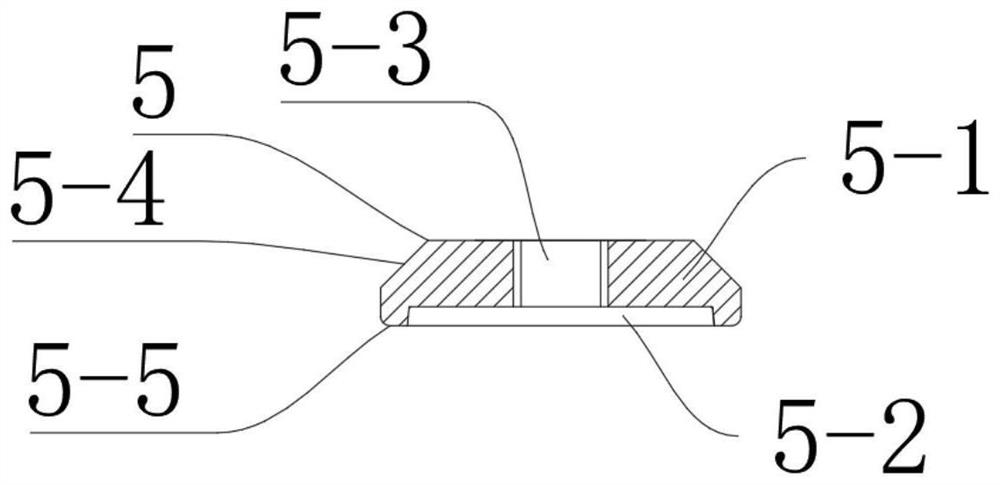

[0125] The suction disc 3 is engaged with the chuck 5;

[0126] The chuck 5 is fixedly connected to one end of the ball handle 6 through a first nut 7;

[0127] The other end of the ball handle 6 is movably connected with the lower lock nut 8 through a swing rod 9;

[0128] The lower lock nut 8 is fixedly connected to the swing rod 9 through a second nut 10 .

[0129] In this embodiment, the suction disk is engaged with the chuck; the chuck is fixedly connected to one end of the ball handle through the first nut; the other end of the ball handle is movably connected to the lower lock nut through the swing rod. The second nut is used to fix the connection between the lower lock nut and the swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com