Air pressure brake unit and multi-shaft automobile chassis with same

A technology for pneumatic brakes and multi-axle vehicles, which is applied in the direction of brake transmission, brakes, brake components, etc., and can solve the problems of utilization of adhesion between wheels and the ground, limitation of compressed air flow, and reduction of vehicle driving safety. Ensure the normal function, improve the braking response speed, and ensure the effect of timely effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

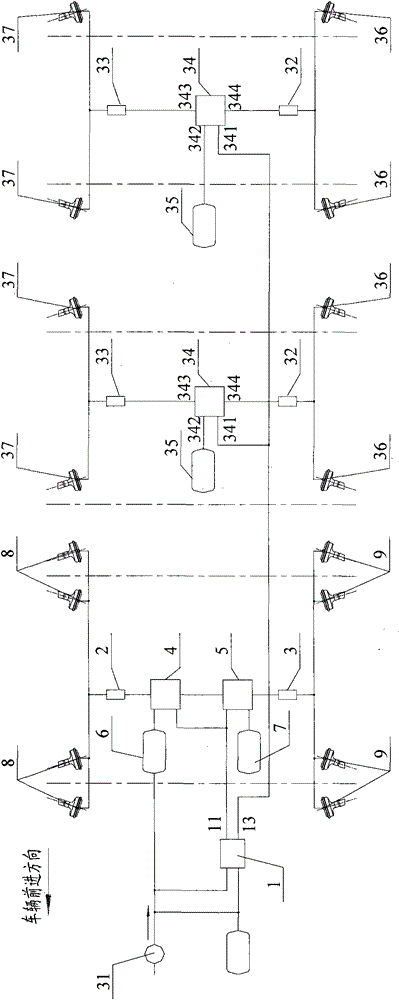

[0026] The core of the present invention is to provide an air brake unit applicable to adjacent multi-axis penetrating balance, so as to ensure the braking efficiency of the vehicle on the basis of reducing the manufacturing cost of the vehicle. Combined with the instructions below

[0027] The accompanying drawings illustrate this embodiment in detail.

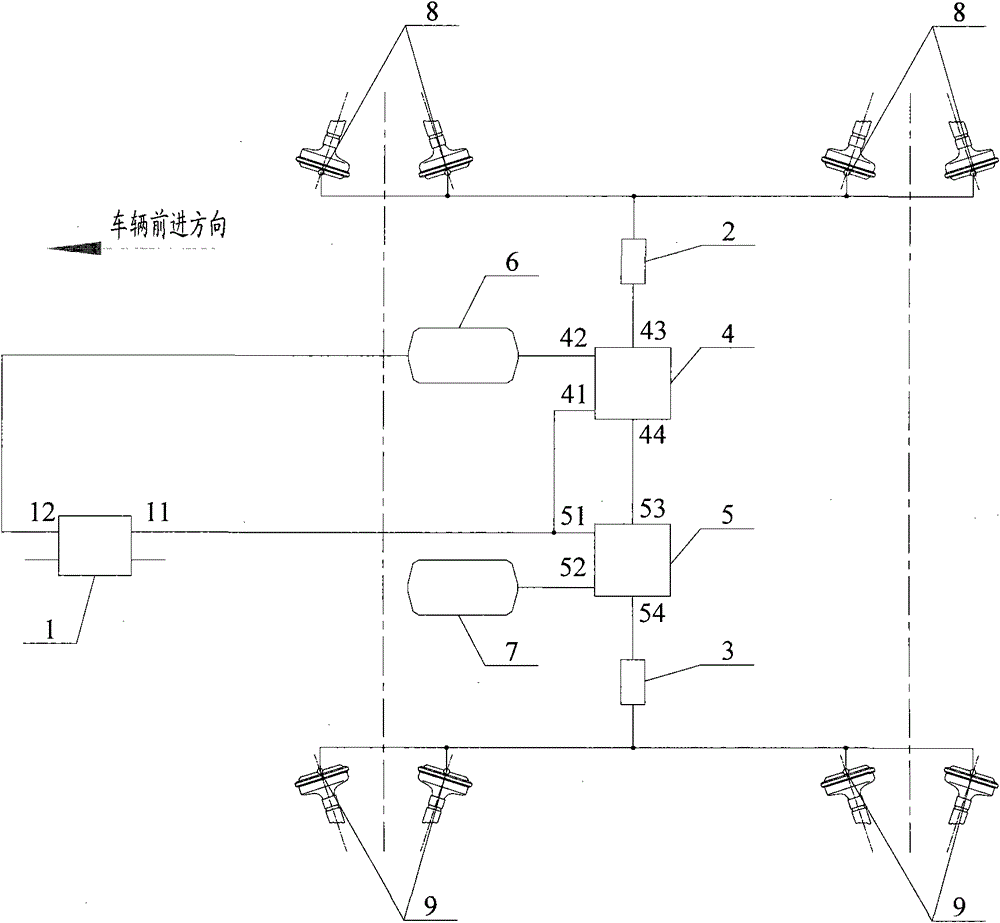

[0028] See figure 1 , which is a schematic diagram of the air brake unit in this embodiment.

[0029] The pneumatic brake unit mainly includes a foot brake valve 1, a first solenoid valve 2, a second solenoid valve 3, a first foot relay valve 4, a second foot relay valve 5, a first air storage tank 6 and a second storage tank. Inflator7.

[0030] Wherein, the air outlet 11 of the first chamber of the foot brake valve 1 communicates with the control air port 41 of the first foot relay valve 4 and the control air port of the second foot relay valve 5 respectively.

[0031] The first electromagnetic valve 2 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com