Pipe rotating device

A pipe material and driving device technology, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of low degree of automation, high labor intensity of workers, uneven quenching at the end of pipe material, etc., achieve high degree of automation and reduce labor costs. The effect of labor intensity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

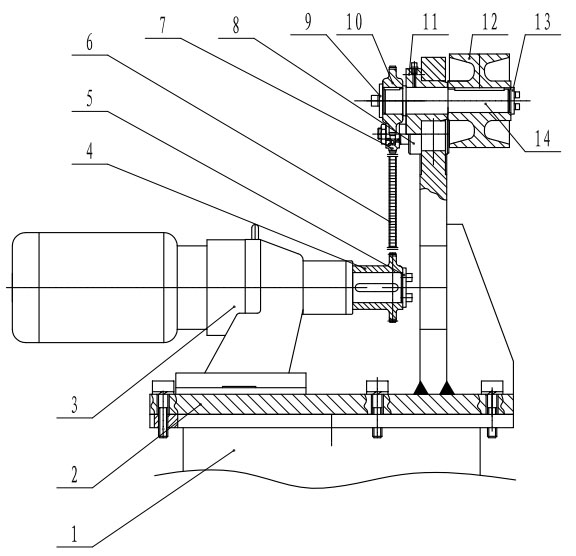

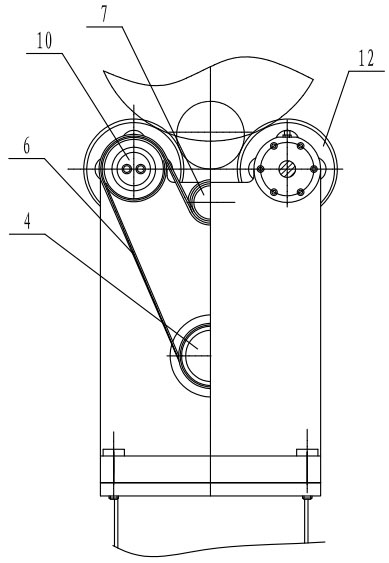

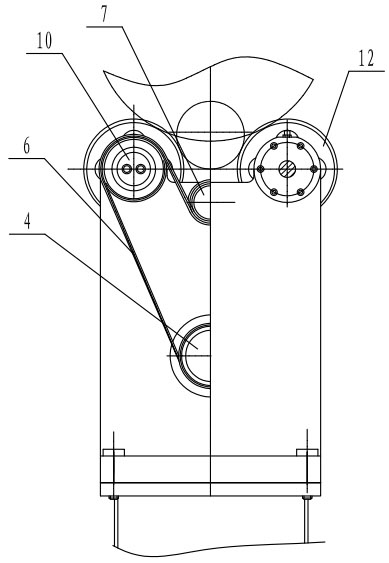

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0010] like Figure 1 to Figure 2 Shown: the present invention mainly consists of base 1, bracket 2, reducer 3, driving sprocket 4, main cover plate 5, chain 6, transition sprocket 7, transition sprocket shaft 8, front axle cover 9, driven sprocket 10, Sliding sleeve 11, drive roller 12, rear axle cover 13, drive shaft 14 etc. constitute.

[0011] The present invention adopts support 2 to be installed on the base 1, and the driving sprocket 4 is fixed on the reducer 3 through the main cover plate 5, the reducer 3 is installed on the support 2, the transition sprocket shaft 8 is installed on the support 2, and the transition sprocket 7 The bearing is mounted on the end of the transition sprocket shaft 8, the sliding sleeve 11 is installed on the bracket 2, the driving shaft 14 passes through the sliding sleeve 11, the driven sprocket 10 and the driving roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com