System and method for controlling zone melting furnace for producing silicon single crystal by using abnormity polycrystalline material

A control system and a technology for zone melting furnaces, applied in the field of zone melting furnace control systems, can solve the problems of melting zone eccentricity, ignition, and broken buds of zone melting silicon single crystals, and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

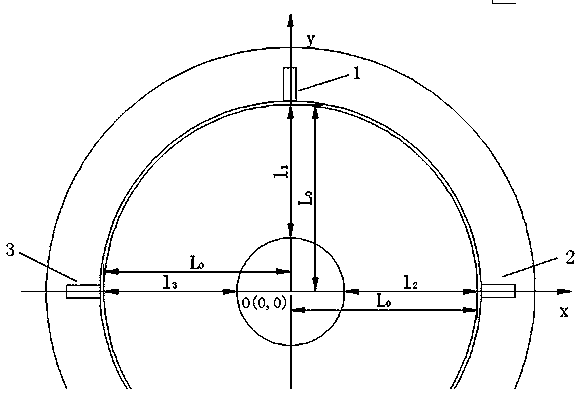

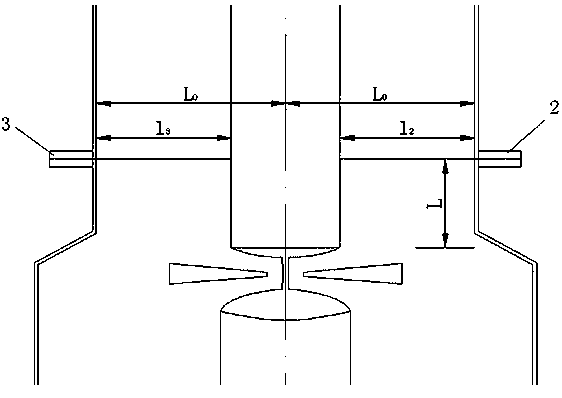

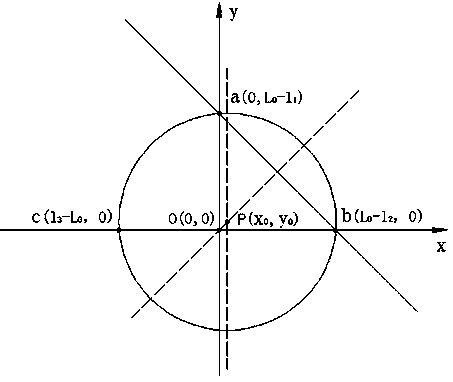

[0052] Embodiment: The model of the zone melting furnace adopted in this embodiment is PVA FZ-30. A coordinate system is established with the center of the furnace as the coordinate origin. The horizontal distance L between the distance meter and the furnace center O 0 is 500mm; the vertical distance L between the range finder and the solid-liquid interface of the polycrystalline material rod is 10mm; after the single crystal grows in equal diameter, the upper shaft speed r is 0.2rpm; the upper shaft speed v is 2mm / min; the polycrystalline material The time t required for the cross section of the rod to reach the solid-liquid interface is 5 min.

[0053] The sampling period in this embodiment is 1 minute, that is, ranging and calculation are performed every 1 minute. Start the system at 16:05, and see the table below for the specific data at 16:15. Among them, the offset vector at 16:10 The offset vector after time t calculated at 16:05 . Offset vector from 16:11 to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com