Full-module-assembly adhesion type lifting scaffold

A lifting and attaching scaffolding technology, applied in the field of scaffolding, achieves obvious economic and social benefits, reduces construction and dismantling costs and steel consumption, and saves steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

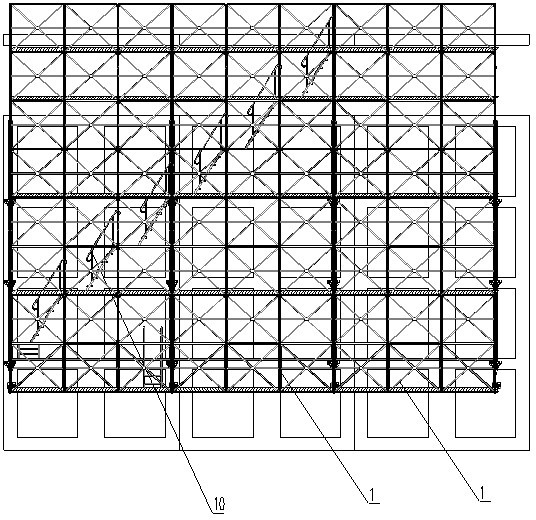

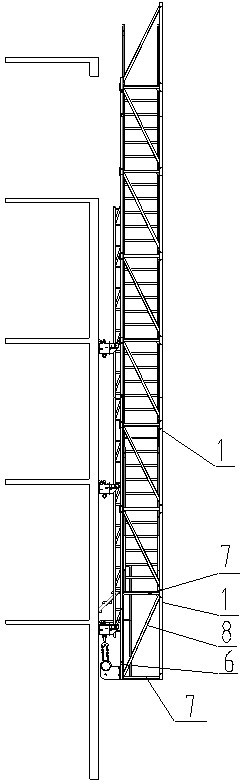

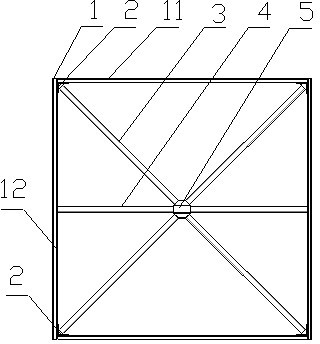

[0039] like figure 1 , 2 , 3, 4, the physical diagram of the whole module assembly attached lifting scaffold of the present invention mainly includes the outer row standard module, the inner row truss module, the vertical main frame module, the ladder module, the steel scaffolding board, the power device (electric hoist) And control system, etc., assembled at the construction site.

[0040] The whole module assembly attachment type lifting scaffold of the present invention comprises the standard modules of the outer row, and the standard modules of the outer row are formed by several standard module frames 1 through the bolt holes on the four sides, and are connected into a whole with bolts; a plurality of standard module frames in the horizontal direction 1 are connected to form a horizontal truss, and a vertical truss is formed after the standard module frame 1 is stacked vertically, and the horizontal truss and the vertical truss form an outer row of standard modules. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com