Composite material viscoelastic damping rod

A technology of composite materials and damping rods, which is applied in the field of spacecraft structures, can solve the problems of more rigidity and strength drops of rods, and achieve the effects of overcoming more rigidity and strength drops, increasing axial damping, and ensuring axial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

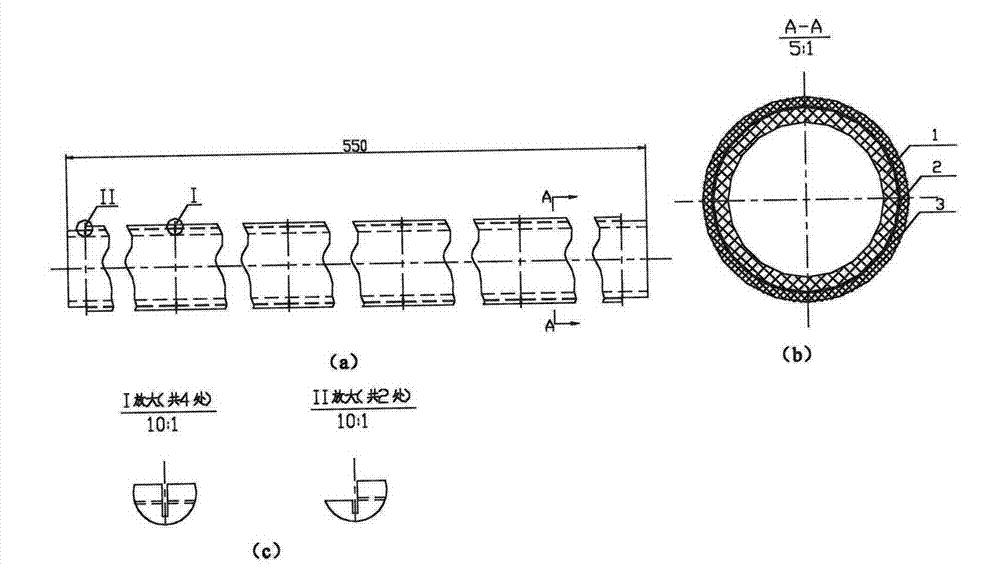

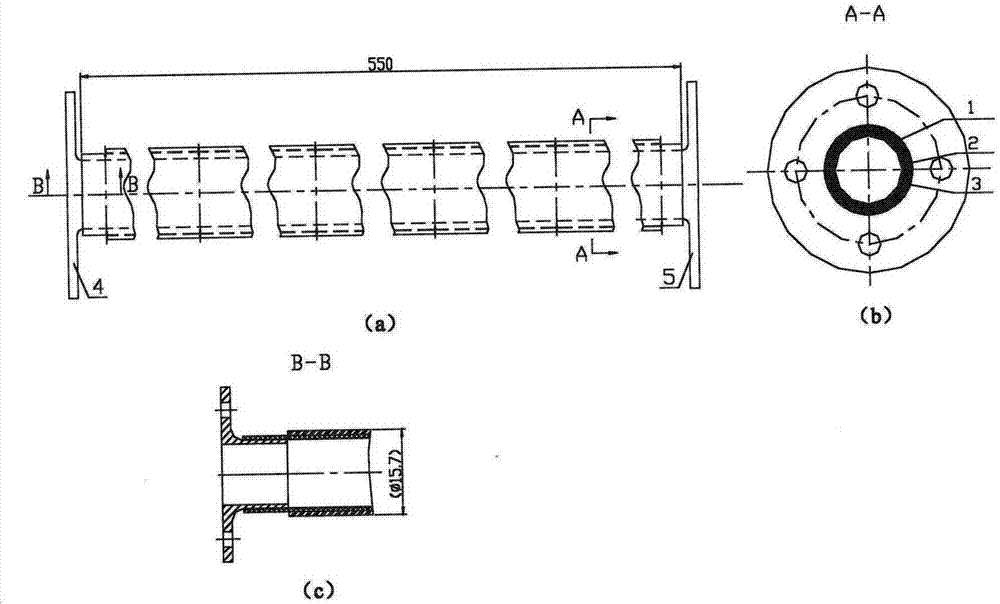

[0017] The viscoelastic damping rod of composite material includes mounting flanges at both ends and a middle rod between the mounting flanges. The middle rod consists of three layers, which are rod body 1, viscoelastic damping layer 2 and constraining layer 3 from inside to outside. Material The design range of the length of the viscoelastic damping rod is 20-1000mm, and the design range of the inner wall diameter is 10-50mm. Lamination is the main layer, with a single layer thickness of 0.125mm. A layer of viscoelastic damping material is pasted outside the rod body. The thickness of damping layer 2 varies from 0.1 to 0.6mm. The material is used as the constrained layer 3, the thickness of which varies from 0.5 to 2.5 mm, and the lay-up design is based on 0° lay-up, with a single-layer thickness of 0.125 mm. The number of segments in the length direction of the rod is 3 to 12, and the segments are realized by designing U-shaped grooves in the circumferential direction of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com