Spherical cavity type solar heat absorber with inwardly concave glass cover

A solar heat absorber and glass cover technology, which is applied to solar heat collectors, solar heat collectors using working fluids, solar thermal energy, etc., can solve the problems of lack of light-to-heat conversion efficiency cavity heat absorbers, etc., to achieve Enhanced light capture ability, less loss of reflected light, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention has been clearly described above, and the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

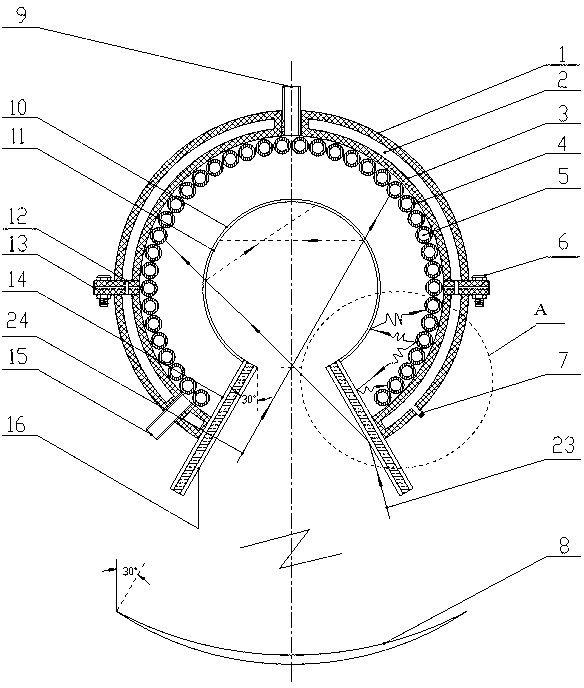

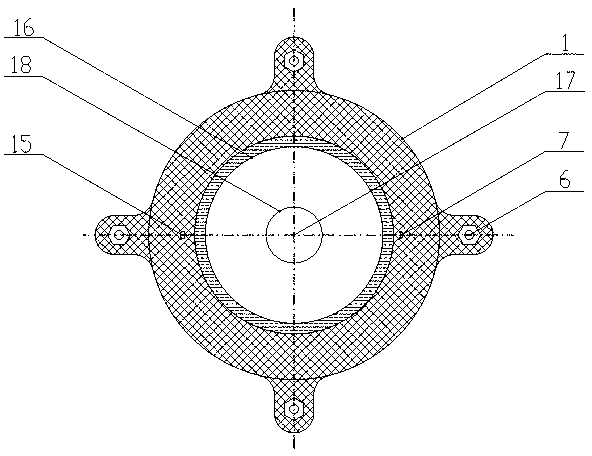

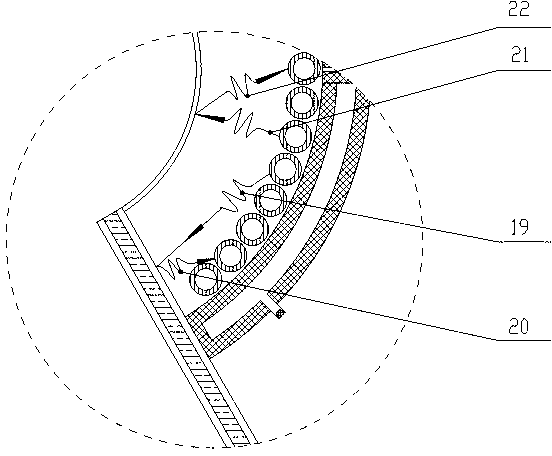

[0031] Figure 1-Figure 2It is a schematic diagram of the structure of the present invention. A spherical cavity solar heat absorber with a concave glass cover includes an outer shell 1; a vacuum layer 2; an inner shell 3; a heat exchange coil 4; a heat transfer fluid 5; bolts 6; air extraction holes 7; The outer wall of the spherical glass cover 10; the inner wall of the spherical glass cover 11; the ventilation hole 12; the rubber sealing ring 13; the inner side of the windshield 14; the fluid inlet 15; the outer side of the windshield 16; The overall structure of the cavity-type heat absorber is a spherical cavity with openings, wherein the structure of the shell is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com