Test method of permeameter contacting with structure in high stress, high hydraulic gradient, and large shear deformation

A shear deformation, high hydraulic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that it cannot be used to guide the design of high earth-rockfill dams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing description, the present invention is described in further detail:

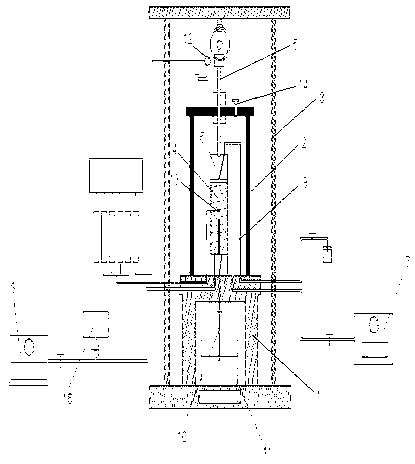

[0021] Such as figure 1 Shown: high stress, high hydraulic gradient and large shear deformation, soil and structure contact permeameter, characterized in that it includes base 1, confining pressure chamber 2, axial pressurizer 3, sample 4, heat shrinkable tube, shaft Pressure bar 5, sample cap 6, permeable stone, confining pressure pressurizer 7, osmotic pressure pressurizer 8, first water outlet pipe 9, second water outlet pipe 10, measuring cup 11, displacement sensor 12, circumferential strain Sheet 13, air relief valve 14, pore water pressure sensor 15.

[0022] The confining pressure chamber 2 is arranged on the base 1; the axial presser 3 is connected to one end of the axial pressure rod 5, and the other end of the axial pressure rod 5 extends from the top end of the confining pressure chamber 2 into the confining pressure chamber 2 , in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com