Gas distribution detection method in coal mine underground goaf

A measurement method and goaf technology, applied in fuel oil testing, material inspection products, etc., can solve problems such as few measurement methods, inability to grasp the gas distribution law, and difficulty in gas distribution measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

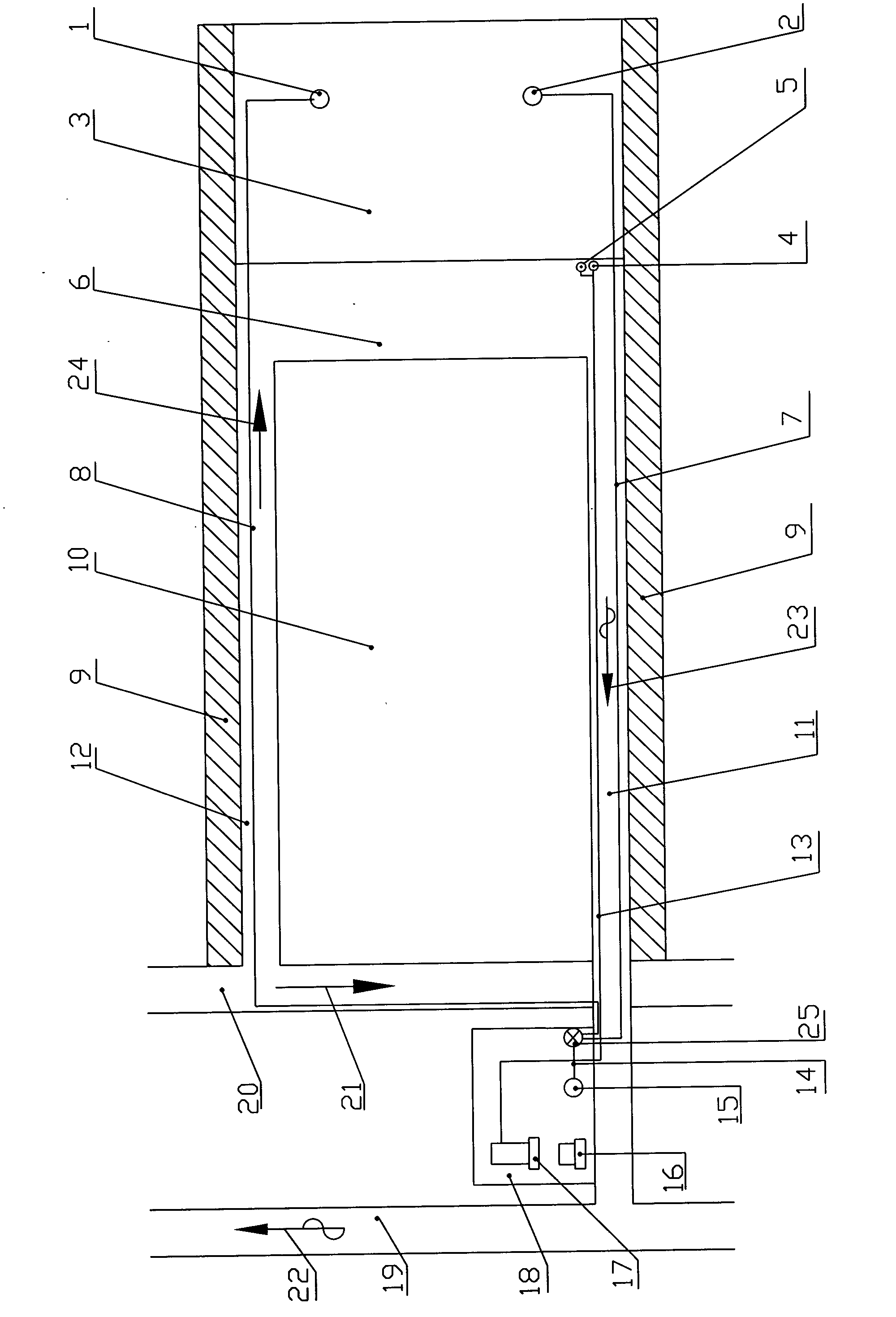

[0047] The present invention will be further described below in conjunction with accompanying drawing:

[0048] figure 1 As shown in the figure, it is the state diagram of gas measurement in the goaf of the coal mine. The position and connection relationship of each part must be correct and operated in sequence.

[0049] The measurement of gas distribution in the goaf is carried out directly in the coal mine. There are coal pillars 9 on both sides of the coal mining face 6 in the coal mine, and the goaf 3 is on the right side of the coal mining face 6 and coal pillar 9. The left part is the mining coal seam 10 of the working face; the air return roadway 11 and the air inlet roadway 12 are set between the coal seam 10 and the coal pillar 9 of the working face, and are connected to each other. The wind tunnel 12 is connected to the air inlet lane 20 in the mining area, and the measurement work cabin 18 is provided between the air return lane 19 and the air inlet lane 20; the go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com