Three-phase dry type magnetic voltage regulator driver for driving cathodic power supply for processing niobium-silicon alloy

A driving device and voltage regulator technology, which is applied in the direction of instruments, electric variable adjustment, control/regulation system, etc., can solve problems such as electron beam current fluctuation, influence on electron beam processing, and unstable output power of cathode power supply, etc., to achieve suppression Influence, improve signal drive capability, smooth and controllable load stepless voltage regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

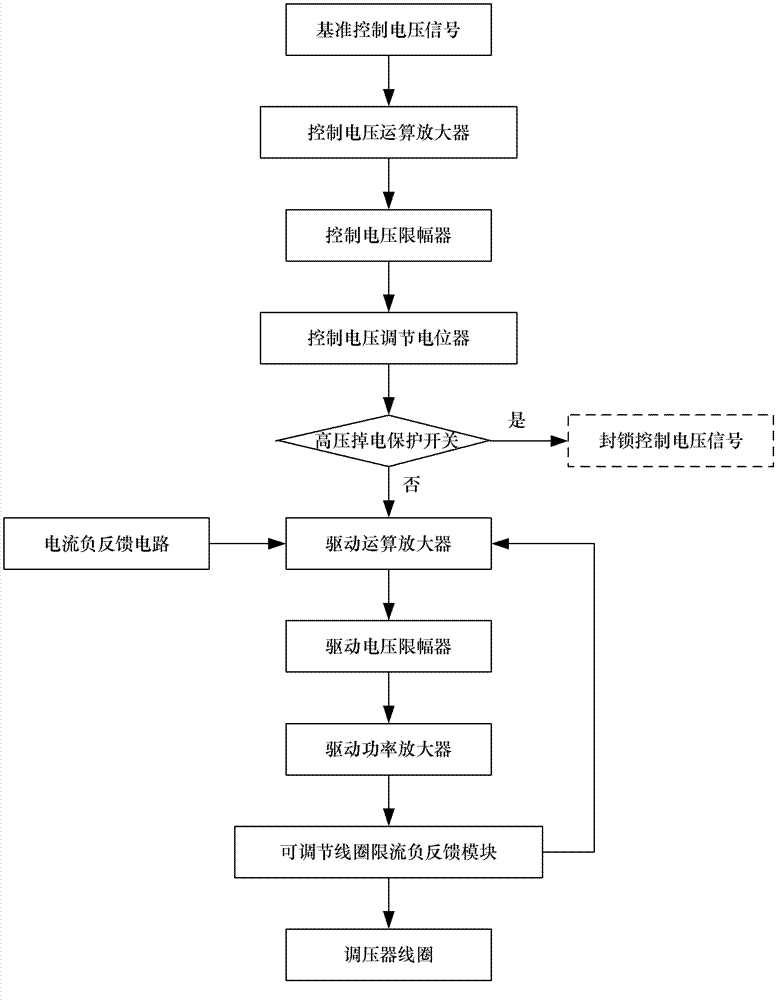

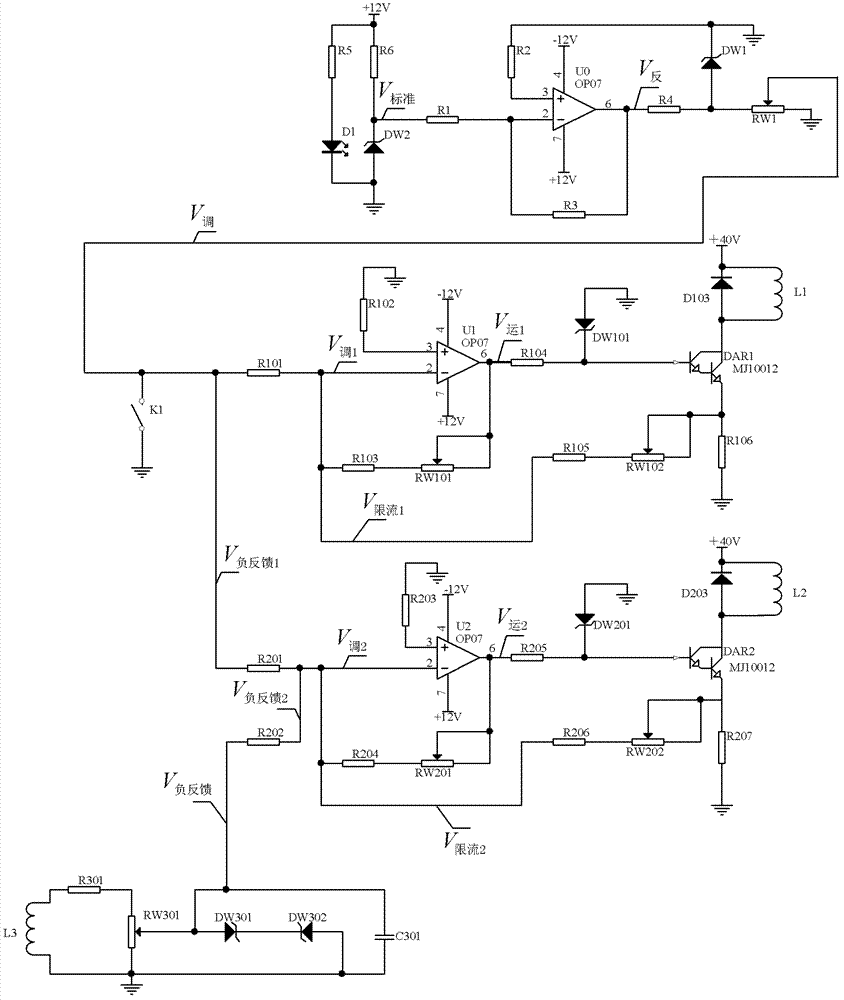

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] see figure 1 As shown, a kind of three-phase dry-type magnetic voltage regulator driving device for driving the cathode power supply of niobium-silicon alloy of the present invention, the driving device includes:

[0033] A reference control voltage signal module

[0034] The reference control voltage signal module is used to obtain the required standard voltage signal V 标准 , the voltage value of the reference voltage is adjusted as required by the Zener tube DW2.

[0035] A Control Voltage Operational Amplifier Module

[0036] The control voltage op amp module is used for the standard voltage signal V 标准 Perform inverting amplification to obtain the required inverting voltage signal V 反 .

[0037] A control voltage limiter

[0038] The control voltage limiter is used to control the inverting voltage signal V 反 Amplitude, to avoid excessive vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com