Multifunctional multilayer insulated wire

A multi-layer insulation and multi-functional technology, applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve the problems of loss of electrical insulation, abrasion of insulated wires, internal slippage, etc., to prevent electrical breakdown and improve wear resistance. The effect of sex, winding convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

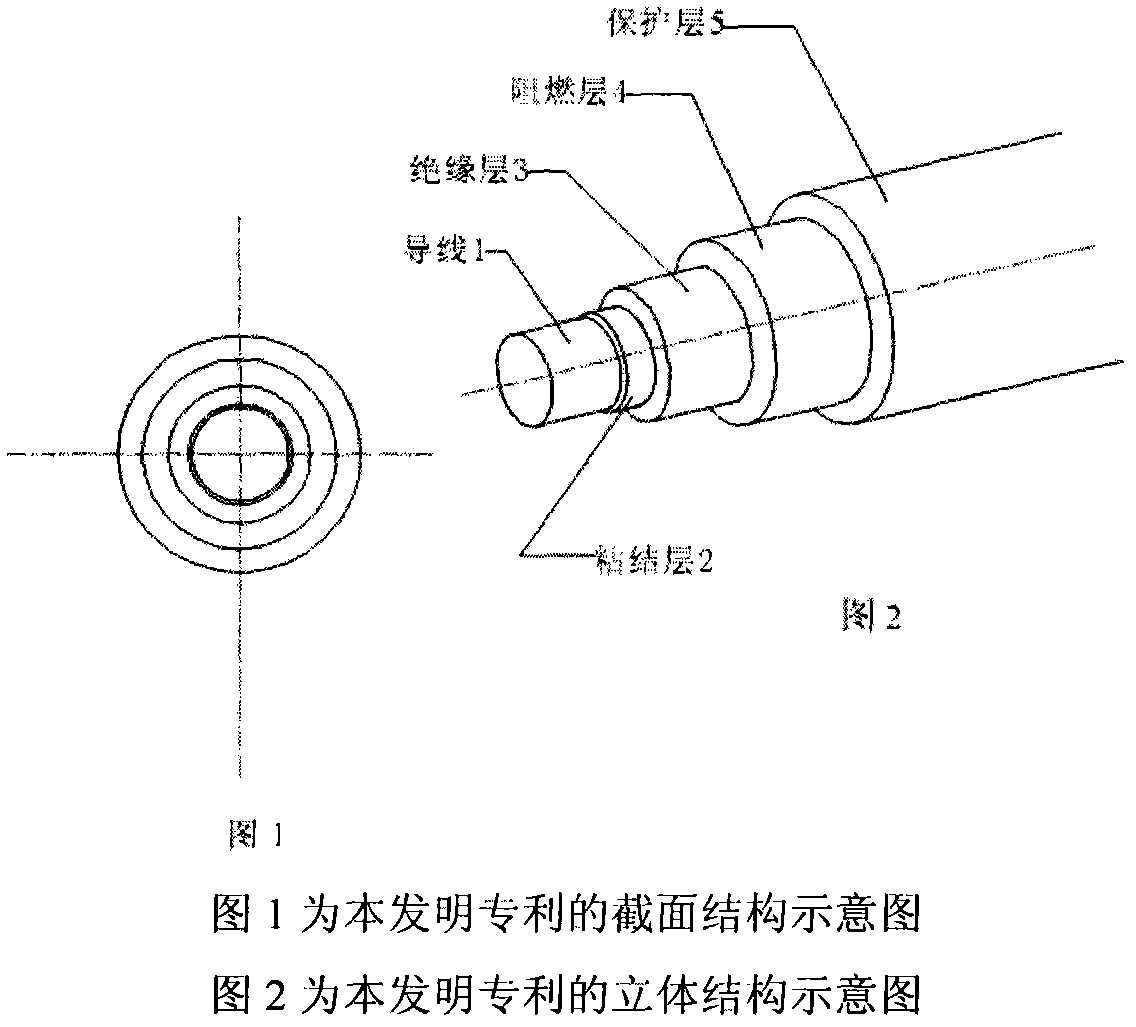

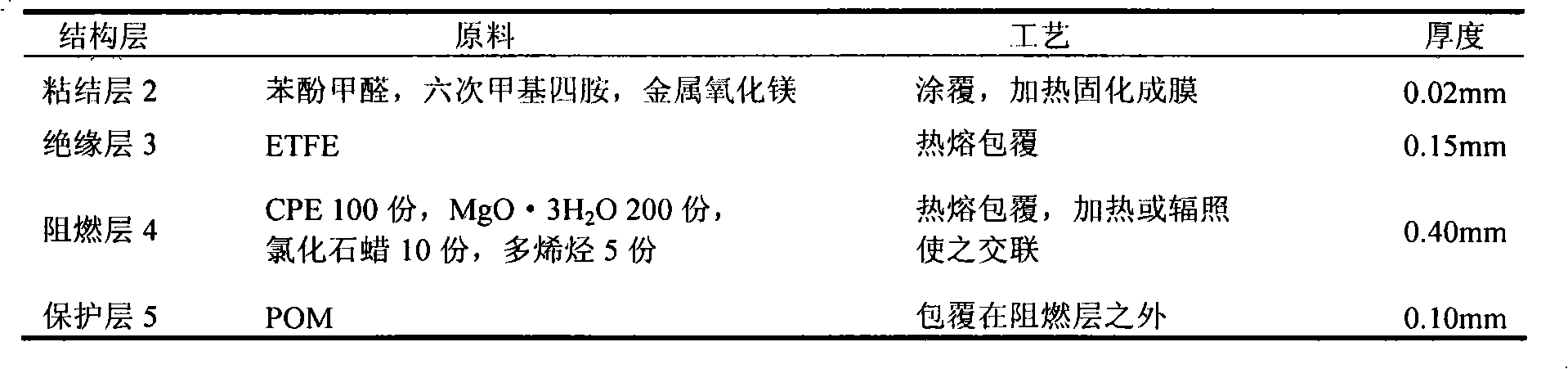

[0010] A multifunctional multilayer insulated wire, which comprises a metal wire 1, an adhesive layer 2, an insulating layer 3, a flame retardant layer 4 and a protective layer 5 (see figure 1 ). The metal wire 1 is copper bare wire, Φ0.5mm, the bonding layer 2 is coated on the outside of the metal wire 1, the insulating layer 3 is covered on the bonding layer 2, and the flame retardant layer 4 is covered on the insulating layer. In addition to the layer 3 , a protective layer 5 covers the flame retardant layer 4 . The specific implementation is as shown in Table 1:

[0011] Table 1 Raw materials and process parameters of multi-functional multilayer insulated wire

[0012]

specific example 2

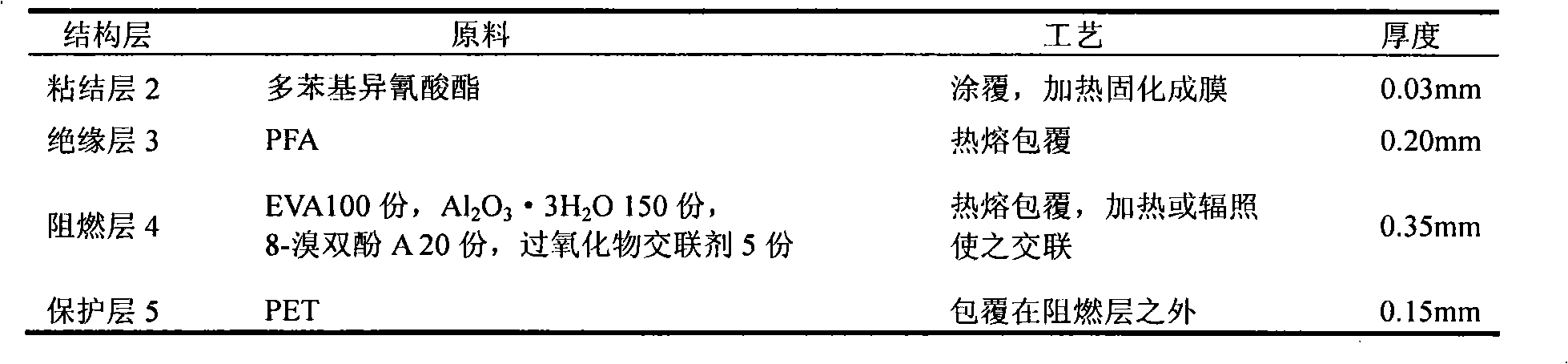

[0014] A multifunctional multilayer insulated wire, which comprises a metal wire 1, an adhesive layer 2, an insulating layer 3, a flame retardant layer 4 and a protective layer 5 (see figure 1 ). The metal wire 1 is a tinned copper wire, Φ1mm, the bonding layer 2 is coated on the outside of the metal wire 1, the insulating layer 3 is covered on the bonding layer 2, and the flame retardant layer 4 is covered on the insulating layer. In addition to the layer 3 , a protective layer 5 covers the flame retardant layer 4 . The specific implementation is as shown in table 2:

[0015] Table 2 Raw materials and process parameters of multi-functional multilayer insulated wire

[0016]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com