Adjusting mechanism for rotor centration by utilizing piezoelectric crystal

A piezoelectric crystal and adjustment mechanism technology, applied in the direction of centering/balancing rotors, etc., can solve the problems of difficult to guarantee adjustment accuracy, long adjustment period, time-consuming and labor-intensive, etc., to achieve simple and fast centering adjustment, large output force, The effect of large bearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

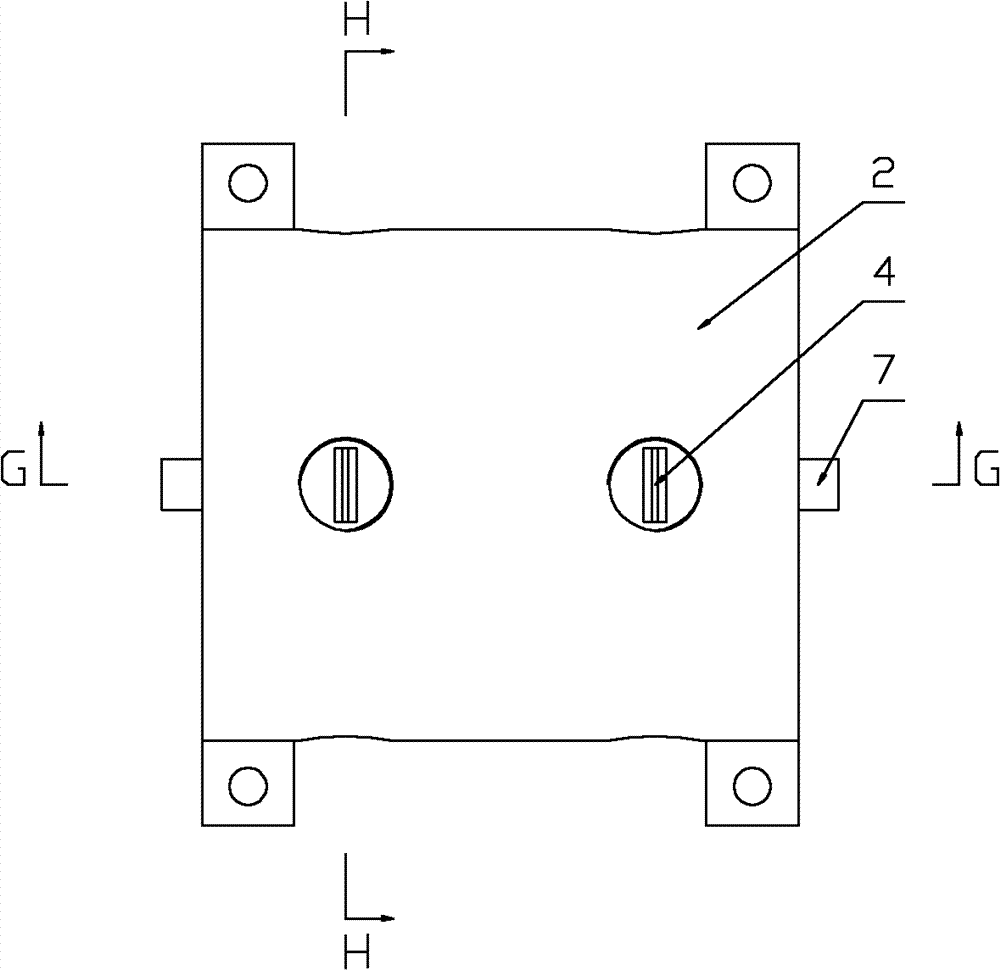

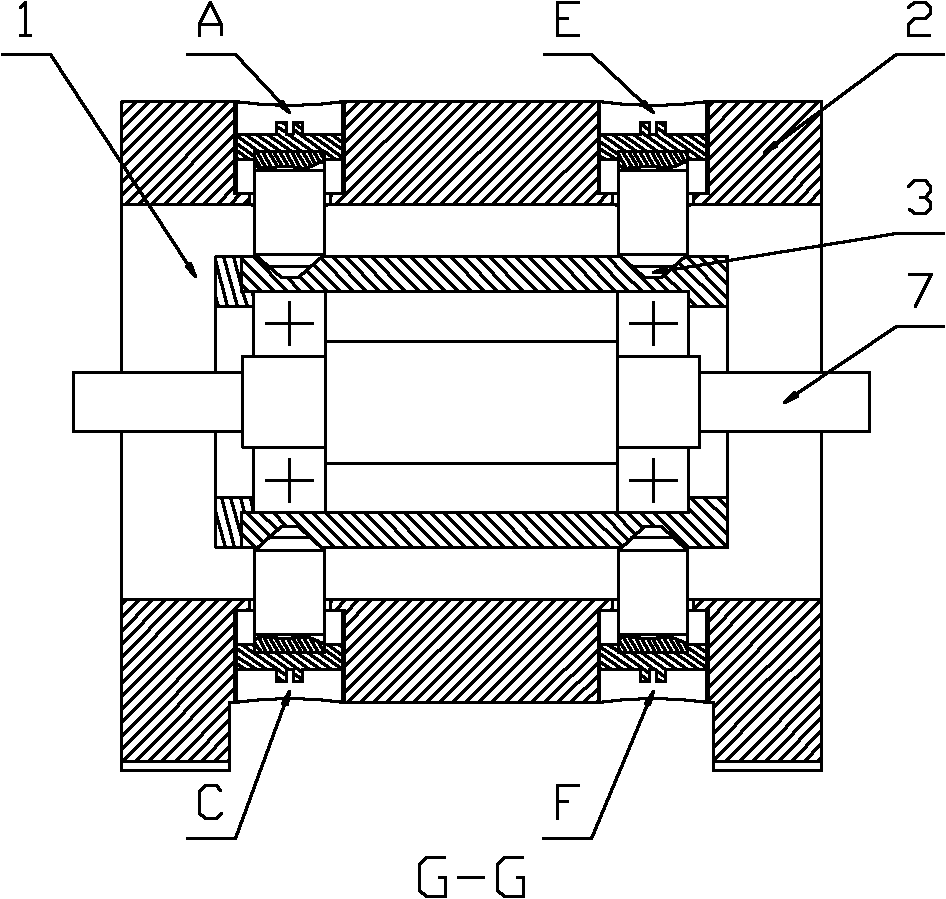

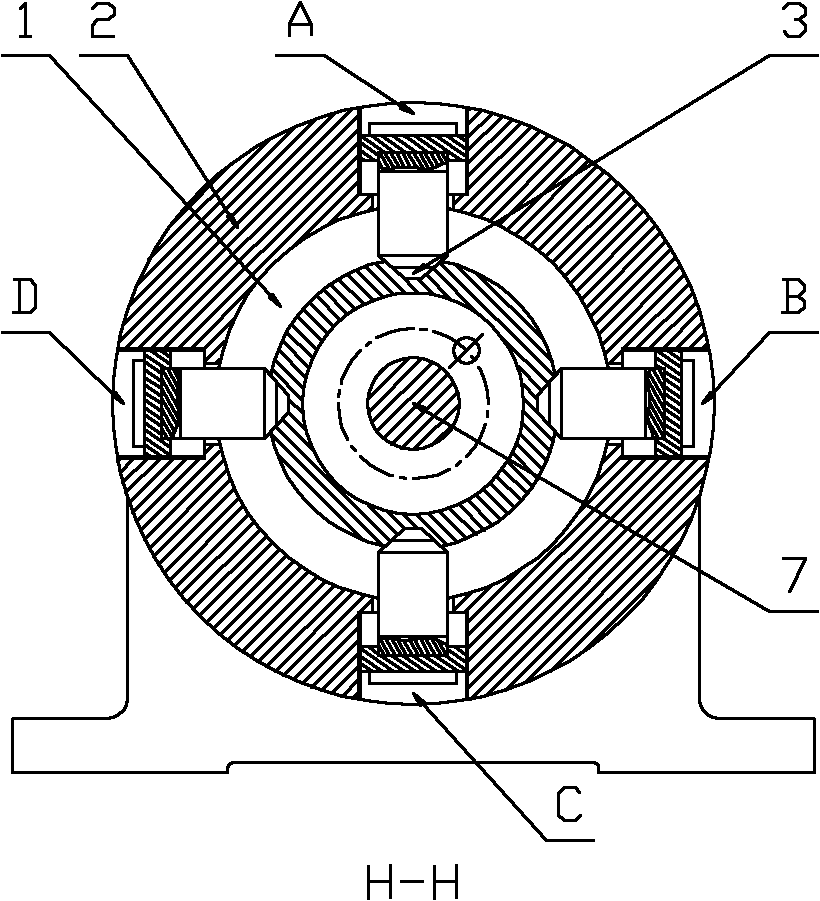

[0015] refer to figure 1 , figure 2 and image 3 , an adjustment mechanism using piezoelectric crystals for rotor alignment, including a bearing-rotor system, the bearing-rotor system is installed in the bearing housing 1, the bearing housing 1 is installed in the housing 2 through the piezoelectric actuator unit, two groups or More than two groups of piezoelectric actuators are distributed along the axial direction of the bearing housing 1 and cooperate with the corresponding conical holes 3 on the bearing housing 1. Each group of piezoelectric actuators includes two or more piezoelectric crystal actuators , the piezoelectric crystal actuators in each group of piezoelectric actuator units are distributed along the circumferential direction of bearing seat 1, refer to Figure 4 , each piezoelectric crystal actuator includes an end cap 4, a heat shrink sheet 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com