Bionic wear-resisting deep-digging shovel blade

A deep loosening shovel and bionic technology, applied in agricultural machinery and implements, applications, plows, etc., can solve the problems of increased manufacturing cost and use cost, high price, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

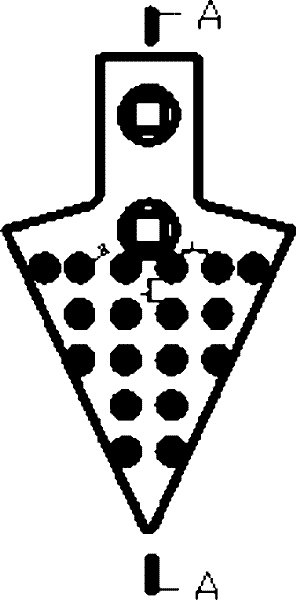

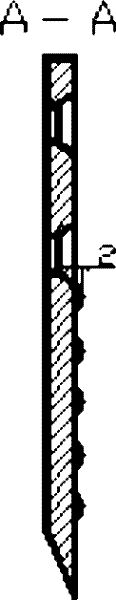

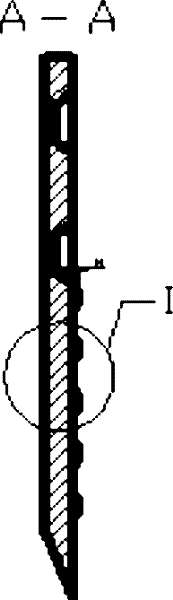

[0037] Example 1 Refer to Figure 1a, Figure 2a, Figure 2b, Figure 2c:

[0038] Fig. 1a and Fig. 2a are the structural diagram and size diagram of the regularly distributed pack-shaped bionic subsoiler blades, and Fig. 2b and Fig. 2c are the dimension diagrams of the cross-distributed and randomly distributed pack-shaped subsoiler blades. The sliding speed of the soil on the surface of the subsoiler blade is 1.94m / s, the size of the soil particles is 0.214-0.420mm, and the direction of the impact velocity of the soil is at an angle of 35° to the surface of the blade. According to the above conditions and considering the size of the deep loose cutting edge, the height of the envelope is determined to be 2 mm, the radius of the ball where the envelope is located is 5 mm, and the ratio of the height of the envelope to the diameter of the bottom circle is 2:8. Therefore, the contour equation of the envelope is obtained for: x 2 +y 2 +z 2 =5 2 , where, 4mm≤x≤5mm, 4mm≤y≤5mm, 3mm≤...

example 2

[0039] Example 2 Refer to Fig. 1b, Fig. 3a, Fig. 3b, Fig. 3c, Figure 3d :

[0040] Fig. 3 is a structural schematic diagram and dimension diagram of ribbed-shaped bionic subsoiling blades distributed laterally. Among them, Figure 3a is a continuous regular distribution; Figure 3b is an intermittent regular distribution; Figure 3c is an intermittent cross distribution; Figure 3d is an intermittent random distribution. The sliding speed of the soil on the surface of the subsoiler blade is 1.94m / s, the size of the soil particles is 0.214-0.420mm, and the direction of the impact velocity of the soil is at an angle of 35° to the surface of the blade. According to the above conditions and considering the size of the sub-loosening blade itself, the height of the rib is determined to be 2.8mm, and the length l of the continuous rib is the transverse width of the sub-loosening blade at the position; the length of the intermittent rib is l One-third of the width of the subsoiler cu...

example 3

[0041] Example 3 referring to Fig. 1c, Figure 4a , Figure 4b , Figure 4c , Figure 4d :

[0042] Fig. 4 is a structural schematic diagram and dimension diagram of ribbed bionic subsoiling blades distributed longitudinally. Figure 4a is a continuous regular distribution; Figure 4b Is intermittent regular distribution. Figure 4c is an intermittent cross distribution; Figure 4d is an intermittent random distribution. The sliding speed of the soil on the surface of the subsoiler blade is 1.94m / s, the size of the soil particles is 0.214-0.420mm, and the direction of the impact velocity of the soil is at an angle of 35° to the surface of the blade. According to the above conditions and considering the size of the sub-loosening blade itself, the height of the rib is determined to be 2.8mm, and the length l of the continuous rib is the longitudinal dimension of the sub-loosening blade at the position; the length of the intermittent rib is l It is one-half or one-third of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com