Device for producing rod-shaped articles from the tobacco processing industry

A technology for the tobacco rod and processing industry, which is applied in the field of devices for producing rod-shaped products in the tobacco processing industry. It can solve the problems that the shape of the scraper is not specified in detail, and achieve the effects of reducing heat generation, reducing head drop, and reducing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

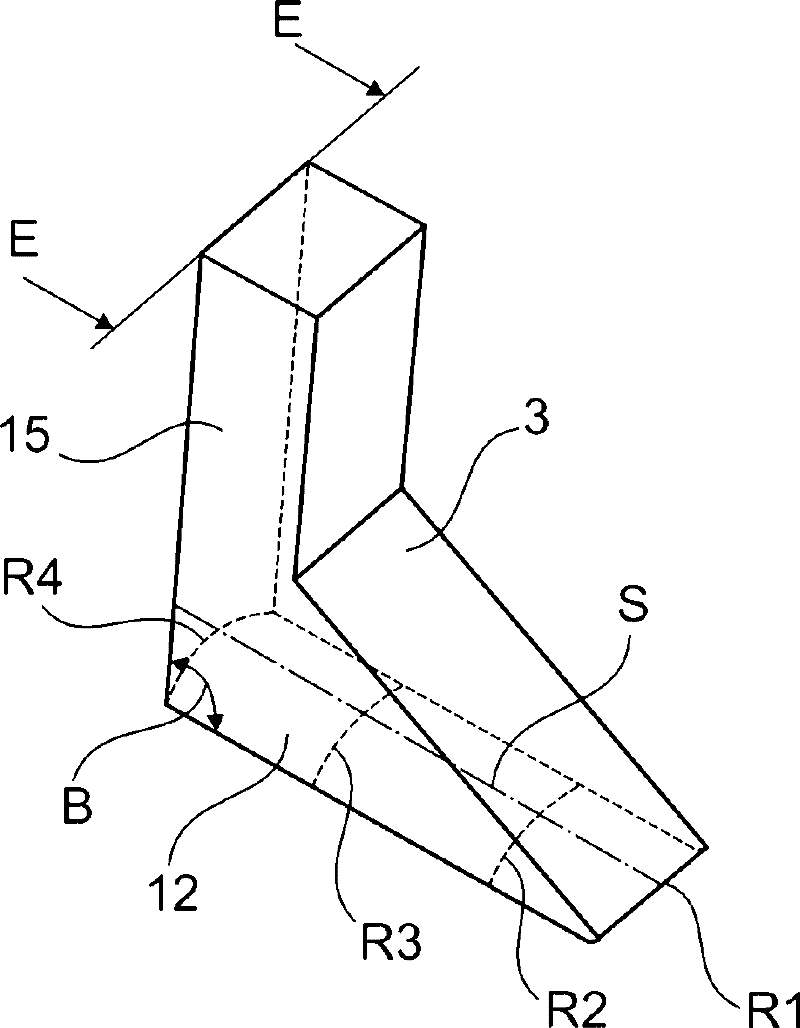

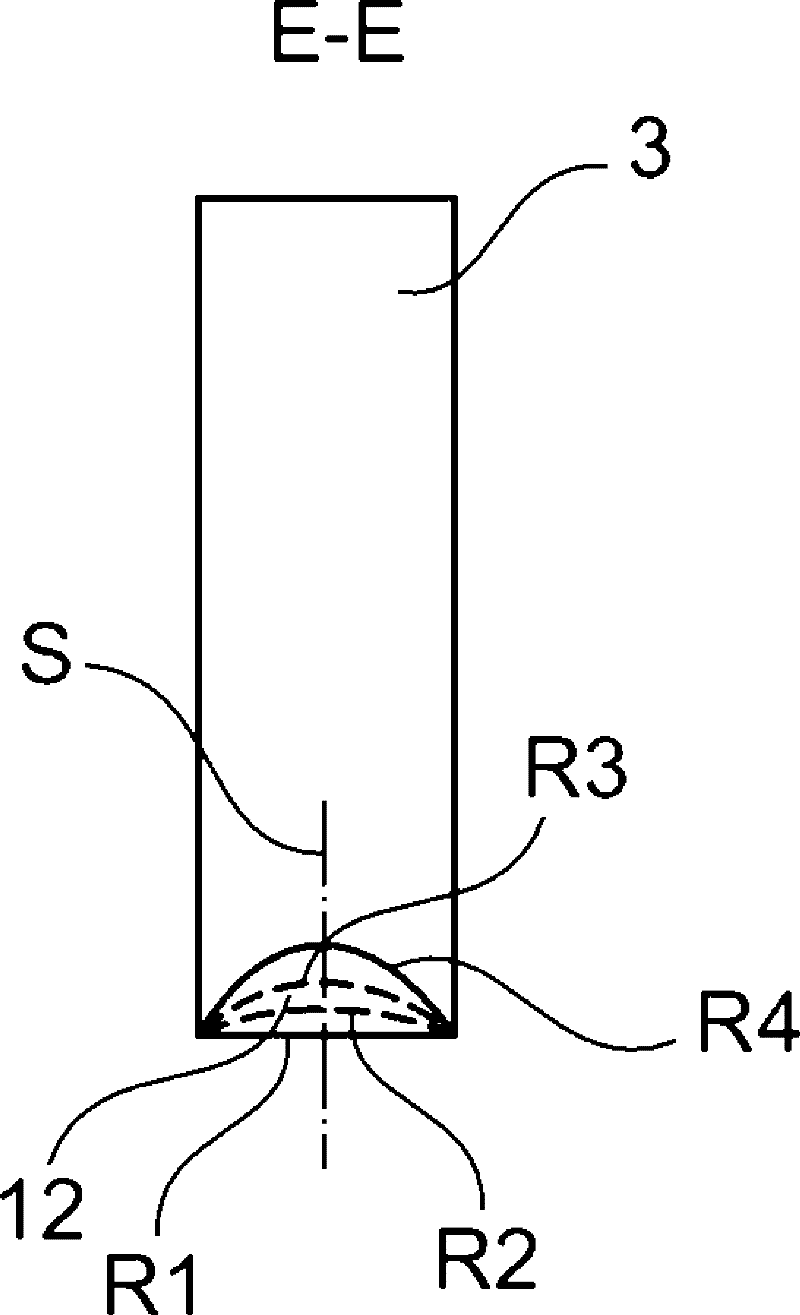

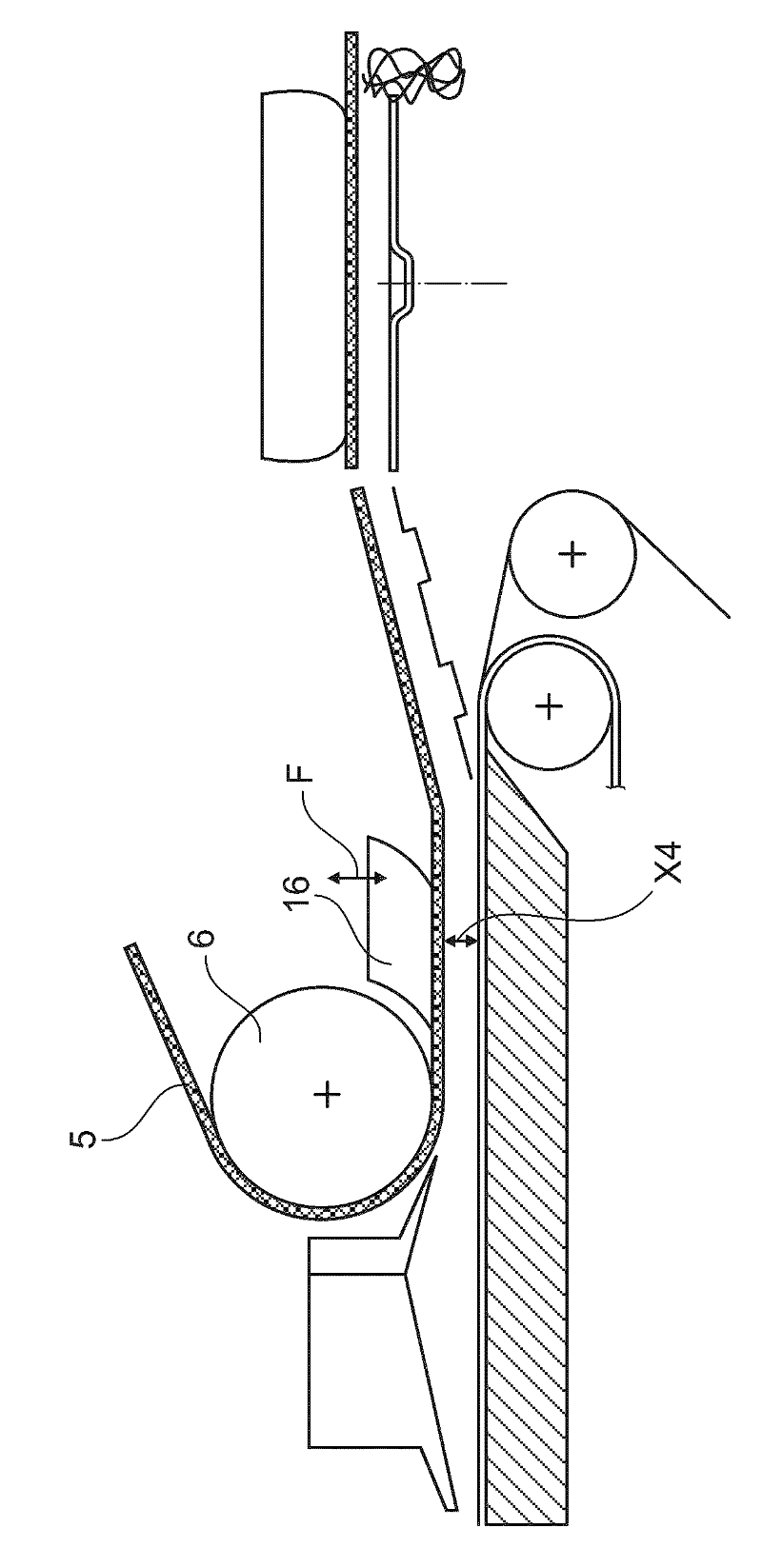

[0034] exist figure 1 A device according to the invention can be seen in the figure, in which a disordered tobacco volume 7 homogenized in an upstream homogenizer is sucked by a perforated continuous conveyor belt 5 by means of low pressure. On one side of the continuous conveyor belt 5 there is provided a weight adjustment shoe 9 . This adjustment shoe can move in the direction of arrow C. Arranged on the opposite side of the continuous conveyor belt 5 is a trimming device 14 in the form of one or more rotating cutting discs and each having one or more grooves 8 . The distance between the continuous conveyor belt 5 and the finishing device 14 can be changed by moving the weight adjustment shoe 9 in the direction of the arrow C. During continuation, the continuous conveyor belt 5 wraps around the guide roller 6 and is driven in the direction of the arrow D by a drive not shown. By the movement of the continuous conveyor belt 5 in the direction of the arrow D, the adhering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com