Spring type automatic frying pan

An automatic frying pan and clockwork technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as unusable, food hygiene, and difficulty in popularizing cooking utensils, and achieve extended time, sufficient and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

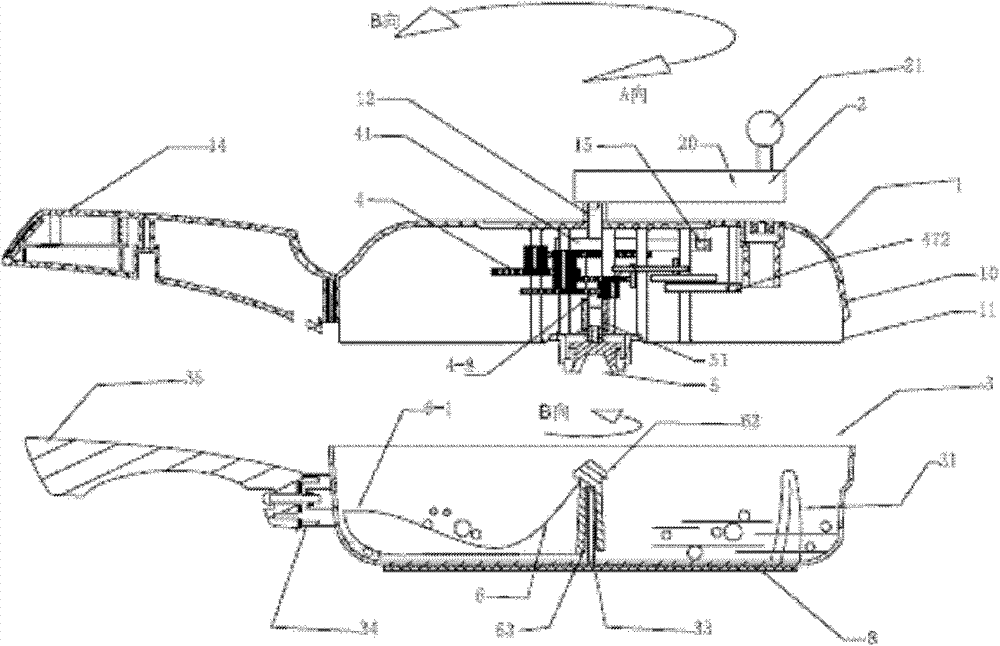

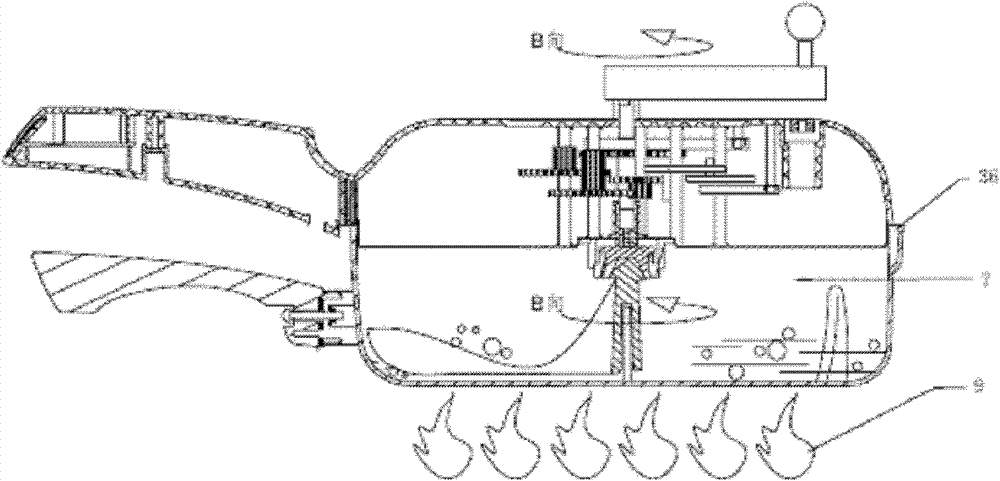

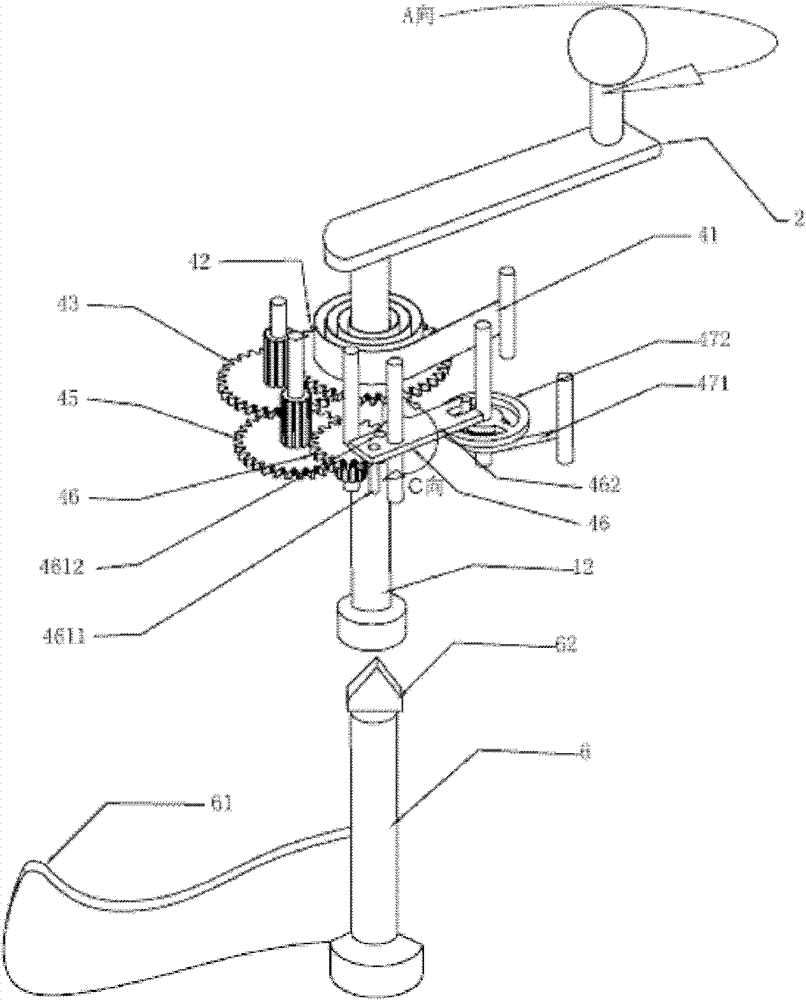

[0023] see figure 1 , figure 2 , a spring-type automatic frying pan, including a pot body 3, a stirring rake 6 for stirring food is arranged in the pot body 3, and a spring-type power device for driving the stirring rake 6 to rotate is provided in connection with the stirring rake 6 4; clockwork power device 4 includes a power clockwork spring 41 connected in sequence for storing energy, a transmission gear set for transmitting energy, a limit swing bar assembly 46 for limiting the speed of the transmission gear set, and for determining The fixed-speed swing assembly 47 of the swing frequency of the limit swing rod assembly 46, the spring power device 4 is provided with a rotating handle 2 for increasing the torque to the power spring 41, and the pot body 3 is provided with a pot body central axis in the vertical direction. 33. The stirring rake 6 is rotationally connected with the central axis 33 of the pot body. The pot cover 1 for sealing the pot body 3 is arranged at the...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the pot body 3 in Embodiment 1 is provided with an internal heat source 8 at the bottom, such as an electromagnetic coil or resistance wire to heat the food, while the bottom of the pot body 3 in this embodiment is not The heating body is set, but the pot body is placed on the external heat source 9 and directly grilled, so as to achieve the purpose of heating food. The external heat source 9 can be a gas flame, campfire or other heat sources. The structure and function are the same as in Embodiment 1. This embodiment is also because of its simple structure, food can be cooked without a power source, and it is especially suitable for situations where the power source cannot be obtained in the wild or remote areas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com