Multi-group tonnage classification control system of hydraulic press

A hierarchical control and hydraulic press technology, which is applied in the field of hydraulic presses, can solve problems such as not being able to meet the actual needs of hydraulic press work, and achieve the effects of reducing processing costs, easy pressing and molding, and saving financial and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

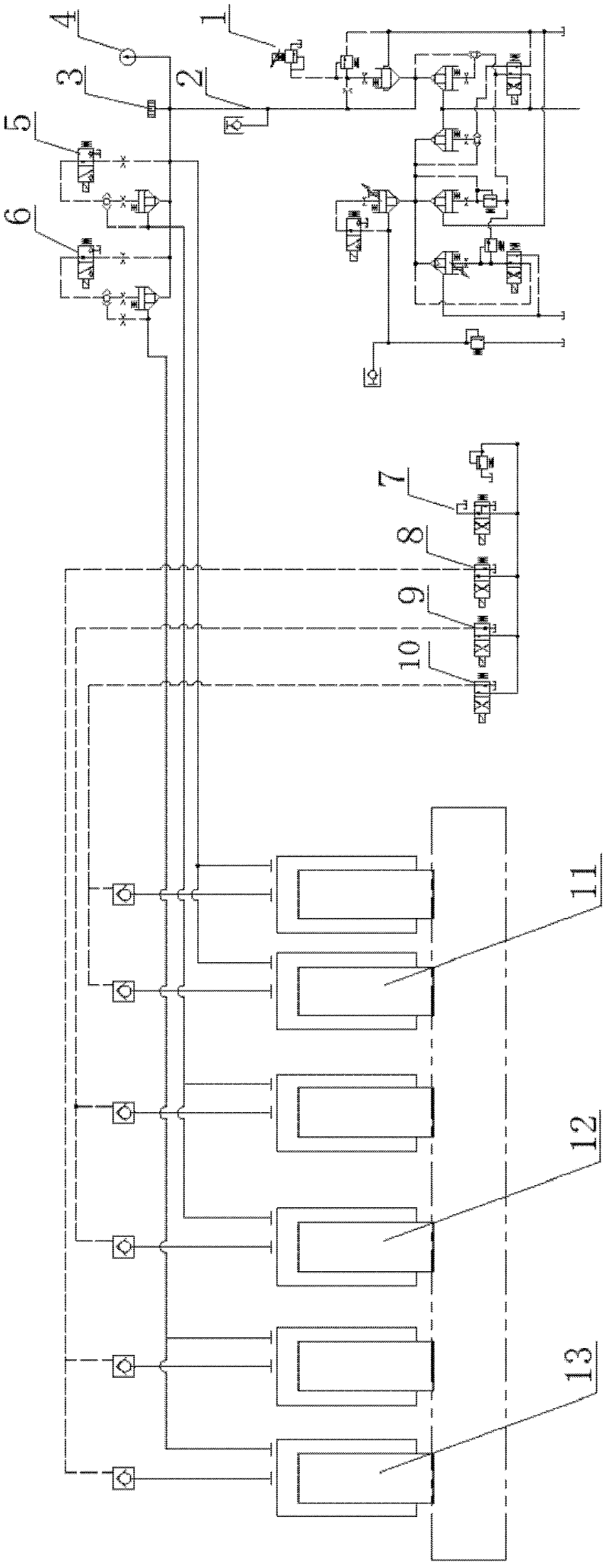

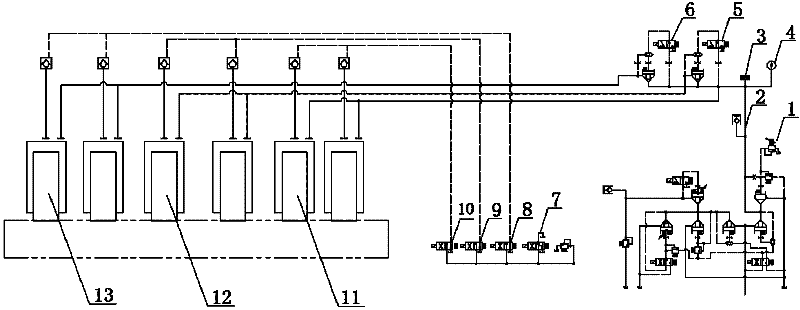

[0018] figure 1 exemplifies a multi-group tonnage grading control system for hydraulic presses with three grading tonnage groups, including three grading tonnage groups, namely the first grading tonnage group 11, the second grading tonnage group 12 and the third grading tonnage group 13, and also includes Fuel tank and connecting oil pipe 2, a proportional relief valve 1 is provided between the fuel tank and the grading tonnage group, that is, three grading tonnage groups form multiple branches of the proportional relief valve 1, and one of the grading tonnage groups passes through the connecting oil pipe 2 It is directly connected to the proportional overflow valve 1, and a solenoid valve is also provided between the other grading tonnage gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com